5 Common Evaporation Materials Used for Industrial Applications

What are evaporation materials? Evaporation materials are used in vacuum deposition processes to produce a thin film on a substrate. They’re commonly utilized in various high-demand sectors, including the electronics, optical, medical and energy industries — and they can have a wide range of properties and applications, depending on the material used.

Discussed below are some common evaporation materials used for industrial applications and how they’re deposited:

1. Aluminum

Aluminum is one of the most widely used evaporation materials due to its low cost, good thermal & electrical conductivity, and high reflectivity. Manufacturers often use aluminum in the production of electronic components, such as integrated circuits and solar cells, making it particularly relevant in the energy sector and developing renewable energy technology.

It is also often used for its reflective coating, which is seen in telescope mirrors, car headlamps, and other optical applications. Aluminum provides a durable coating with high reflectivity.

Aluminum deposition

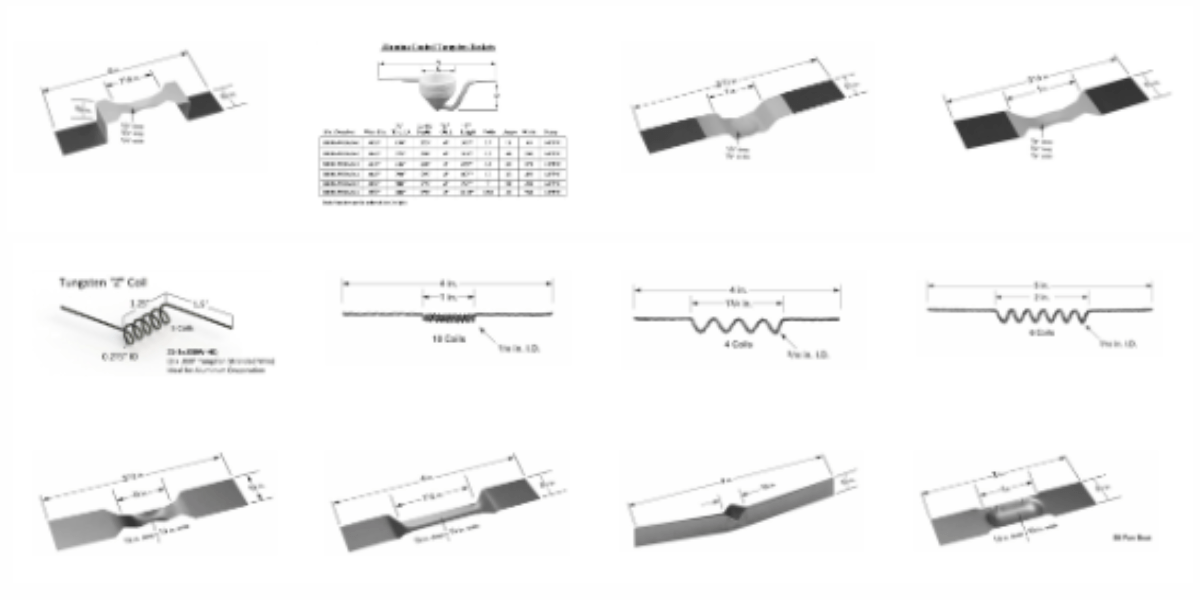

When thermally evaporating this metal, keep in mind that it is corrosive when molten. Use a thick tungsten boat rather than a tantalum or molybdenum boat to maximize the evaporation source’s life.

2. Gold

Gold is a popular evaporation material due to its high electrical conductivity, corrosion resistance, and aesthetic appeal. This metal is commonly used in the production of of optical filters, conductors, and electronic components, where uniform and controlled thickness are required.

Another common application of gold is for jewelry, particularly for the watch industry. Many watch manufacturers use gold PVD coatings for better wear resistance as opposed to less durable methods like electroplating.

Gold deposition

To minimize the loss of gold, use alumina coated evaporation sources (such as alumina coated boats or alumina coated tungsten baskets) to prevent the gold from escaping the evaporation area. This ceramic layer of alumina prevents molten gold from wetting, ensuring that it evaporates properly and effectively.

3. Silver

Silver is another popular evaporation material due to its high electrical conductivity and reflectivity. The conductive properties of silver are utilized within the construction of various types of electronic components, such as microchips and solar panels.

For visual appearance, PVD is one of the methods of giving high-end utensils their shiny appearance: hence the name “silverware”. Historically, manufacturers have also made mirrors using silver as the reflective surface.

Silver deposition

In most cases, silver is a simple material for thermal evaporation. Choose a molybdenum or tantalum boat source based on the capacity of silver needed for your thin film application.

4. Chromium

Chromium is a hard and corrosion-resistant metal that is commonly used as an evaporation material in the production of printed circuits, reflectors and adhesion layers between multiple layers of coatings. As opposed to traditional chrome plating (electroplating), PVD serves as an alternative method for applying environmentally-friendly chromium coatings.

Chromium deposition

For chromium, it is recommended to evaporate it from a tungsten rod source (CRW).

5. Titanium

Titanium, a strong, lightweight, and corrosion-resistant metal, serves as an thin film material in the production of aerospace components and electronic devices. Additionally, this resistance to corrosion makes titanium a highly biocompatible material. The medical device industry uses titanium as a biomaterial for coating surgical implants and tools.

Titanium deposition

We recommend to use a tungsten boat for the thermal evaporation of titanium.

RD Mathis Company’s Evaporation Materials

Overall, the choice of evaporation material depends on the specific properties required for the thin film produced and the intended application. We offer a wide selection of high-purity, vacuum-ready evaporation materials in several forms — including difficult to source materials, sizes, and purities upon request.

For over a half-century, we’ve brought a higher level of quality and innovation to meet even the most challenging customer needs. With our innovative technical expertise, RD Mathis Company can solve evaporation source problems for your film process.

View our selection to get started or contact us about source solutions.