0

You have 0 items in your cart

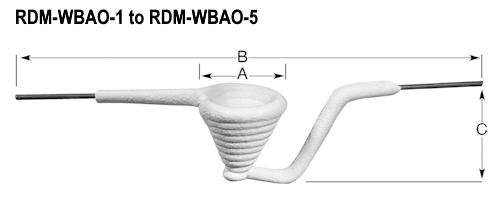

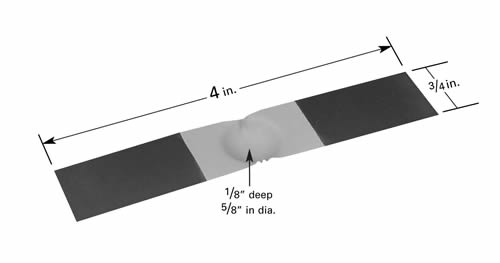

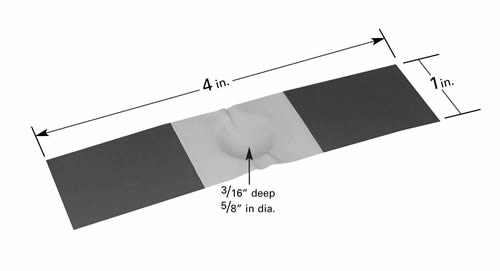

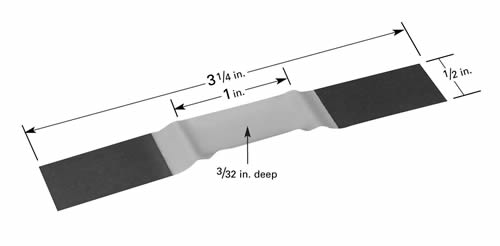

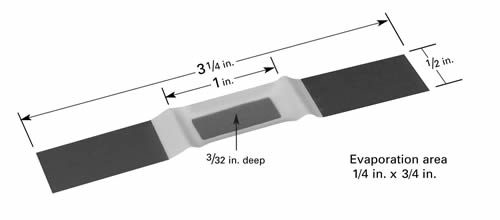

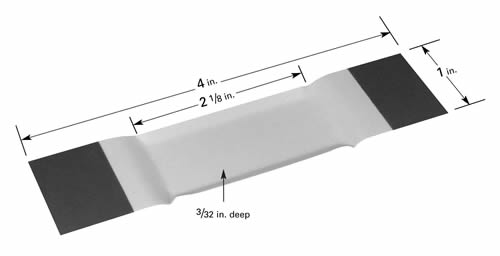

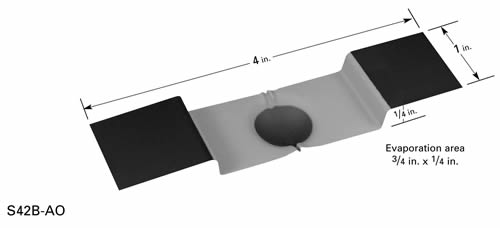

Aluminum oxide coated evaporation sources were developed to replace alumina crucible boats for some specific applications. Advantages of this evaporation source include good heat transfer and inertness of alumina (AO) with most metals. Additionally, evaporant does not wet the alumina resulting in no resistance change of the boat when the material melts. Due to alumina’s non-wetting characteristics, the evaporant forms a sphere when melted, resulting in a point source.

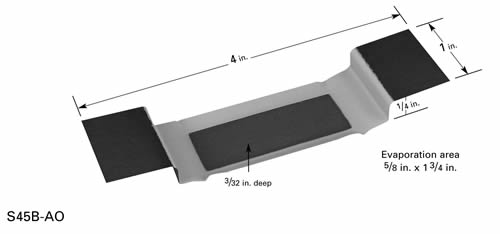

This type of evaporation source will give long life compared to the non-protected sources. Coated sources will require 30-50% more power to affect evaporation due to differences in heat conduction. The semiconductor-grade aluminum oxide is applied to the boat/basket by plasma spray technique. Temperatures of 1850°C should be avoided; when an evaporation is affected, power should be reduced slightly to avoid overheating.

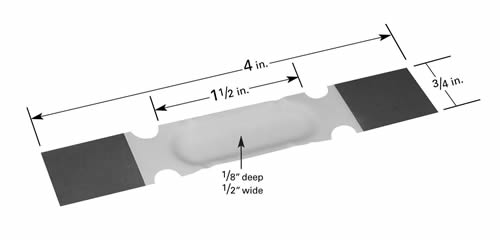

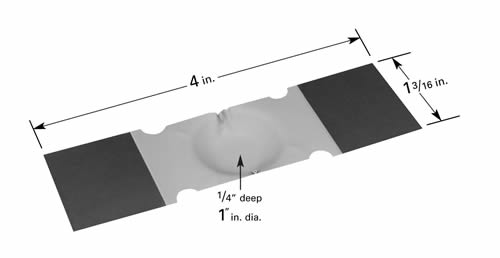

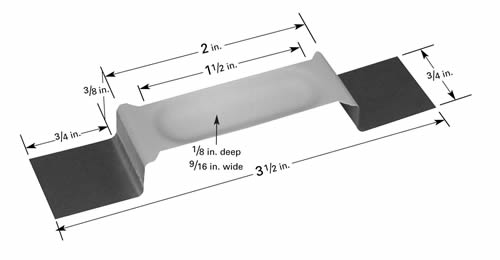

This source has been designed to give the benefit of a refractory metal boat and a ceramic barrier. The exposed metal area in the bottom of the boat allows evaporant to have good thermal contact with the source. An alumina barrier inhibits evaporant from creeping toward the heat sink or wetting the entire boat.