Case Study: Alumina-Coated Tungsten Boat in Semiconductor Manufacturing

In semiconductor manufacturing, controlling material deposition with precision and consistency is critical to device performance and yield. Physical vapor deposition (PVD) techniques are used within this industry to deposit sensitive thin films during the fabrication process using parts such as an alumina coated tungsten boat.

This study examines how alumina-coated boats serve as a robust solution to address challenges during thin film coatings of semiconductor devices.

1. Challenges in Manufacturing

1.1. Thin Film Consistency

Semiconductor manufacturing demands high quality thin films while maintaining adequate efficiency and production rates. For this reason, many physical vapor deposition techniques (PVD) are employed within the manufacturing process, including thermal evaporation.

Film consistency can vary from material to material, especially with materials that exhibit wetting or corrosive properties during the high temperature deposition process. Variables such as these can affect the deposition process, i.e. increasing maintenance or leading to source failure.

2. Solutions: Alumina Coating

2.1. Introduction

Alumina‑coated tungsten boats combine the high melting point and structural resilience of tungsten with the chemical inertness and thermal stability of a ceramic aluminum oxide coating. These parts are stable and perform well in environments up to temperatures such as 2000°C. The configuration enhances performance in several measurable ways in the context of semiconductor fabrication.

2.2. Uniformity

The alumina coating exhibits non-wetting behavior with molten materials, preventing non-uniform depositions. This lack of uniformity can be caused by uneven material wetting and distributing to cooler areas of a boat source.

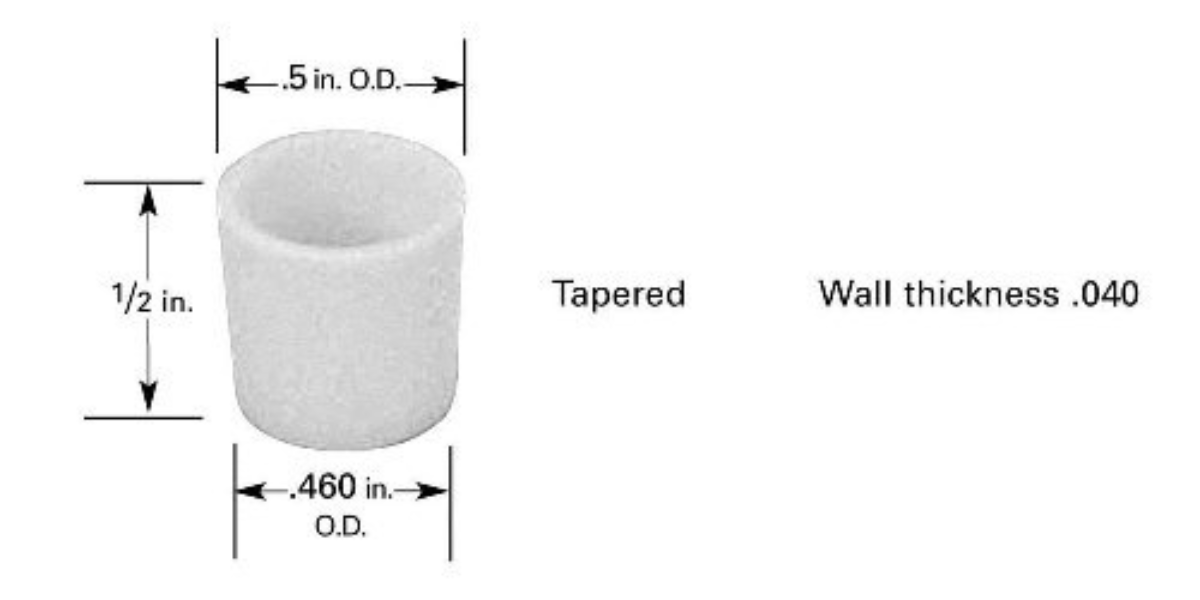

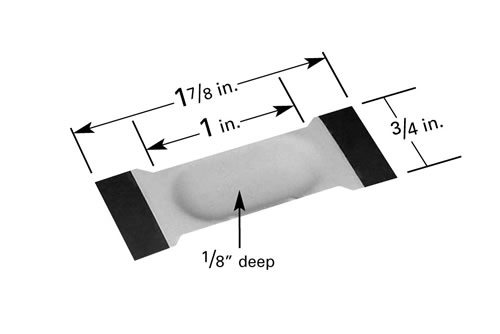

Image: Alumina-coated ME3-AO

By maintaining control over material wetting, alumina-coated tungsten boats help maintain consistent vapor flux. The resulting coating exhibits better thickness consistency for these semiconductor thin film layer applications.

2.3. Chemical Inertness

Contamination is a constant concern in semiconductor manufacturing. It is a potential risk for compromising the reliability of devices being produced. However, alumina-coated tungsten boats minimize the risk of contamination by providing a clean and stable platform for material evaporation.

The inert nature of alumina ensures that no unwanted elements are introduced into the thin films, preserving the integrity of the semiconductor components. This gives them resistant to corrosive or reactive materials that may be used during semiconductor manufacturing, making them valuable components for fabrication processes.

3. Cost Analysis

3.1. Versatility in Deposition

Semiconductor manufacturing encompasses various thin film materials, each with its unique requirements. Alumina-coated tungsten boats prove versatile, adapting to a variety of different materials used in thermal evaporation. This flexibility makes them a preferred choice for manufacturers employing diverse semiconductor fabrication processes.

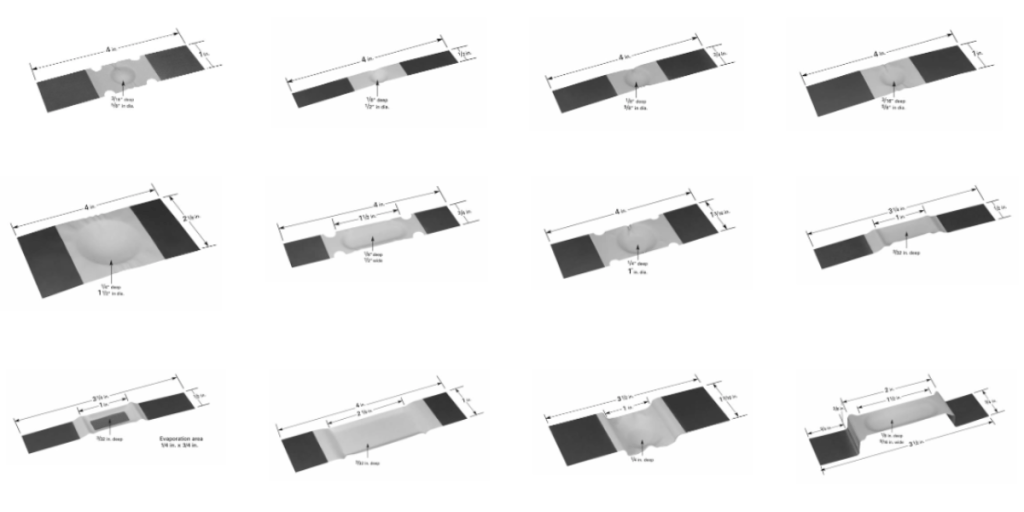

Image: Example selection of alumina coated boat geometries

These sources can be made from tungsten, molybdenum, and tantalum, depending on the compatibility with the evaporation material used in the thin film process. Beyond that, customized manufacturing for these heating element sources are accessible upon request.

3.2. Source Longevity

For many materials, the alumina-coated tungsten boat can increase durability and resistance to wear. This is true in the case of materials that can be corrosive or also mildly corrosive at elevated temperatures. Reduced maintenance and higher utilization rates can contribute to cost savings throughout the process.

Source Alumina-Coated Tungsten Boats

If looking for a range of alumina-coated tungsten boats or other applications of alumina coating, contact the R.D. Mathis Company for more information. As a cutting-edge supplier, our production team offers a diverse range of high-quality products for precise material deposition processes.