Vacuum Components: Handling Tungsten and Other Parts

Vacuum components are chosen for their high temperature resistance, minimal outgassing, and durability. These components include parts fabricated from high purity tungsten, molybdenum, and tantalum. To maintain the lifetime of these components, certain procedures need to be followed to minimize stresses and contaminants.

See the following warning and procedural guidelines for vacuum processes:

1. Material Stresses

Materials used for vacuum components are designed for durability for high performance in demanding conditions. However, cyclic stresses can still contribute to wear and tear on components, which may lead to premature failure that increases maintenance costs.

1.1. Mechanical Stresses

When subject to elevated temperatures, thermal expansion and contraction occurs, even with materials with low coefficients of thermal expansion like tungsten. For some particular components, a lack of allowances for expansion can eventually cause cracking.

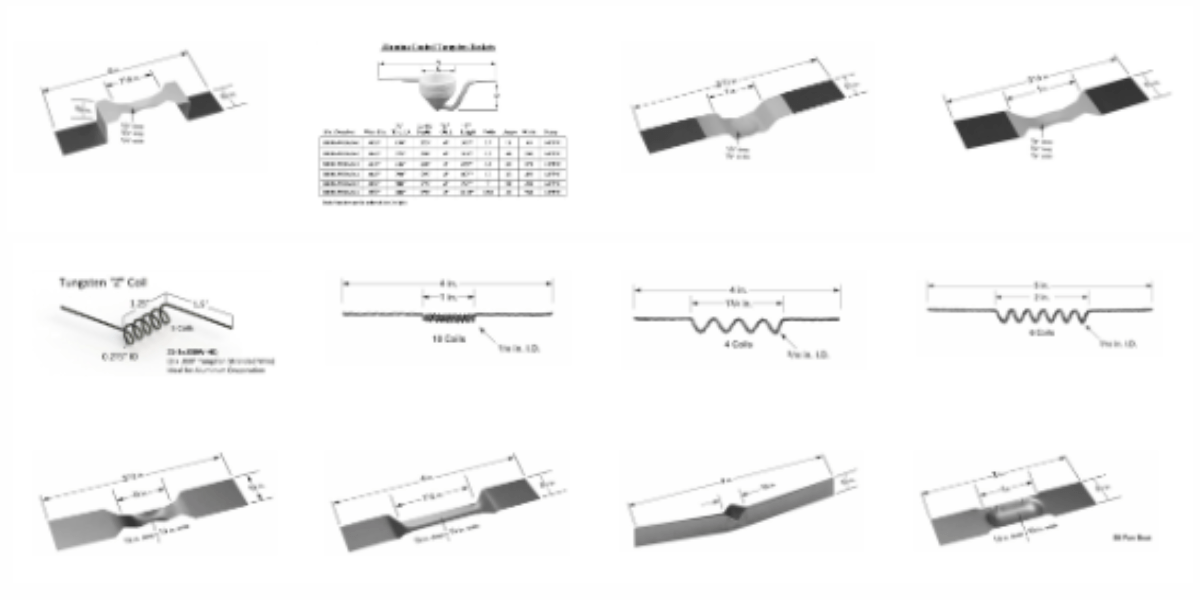

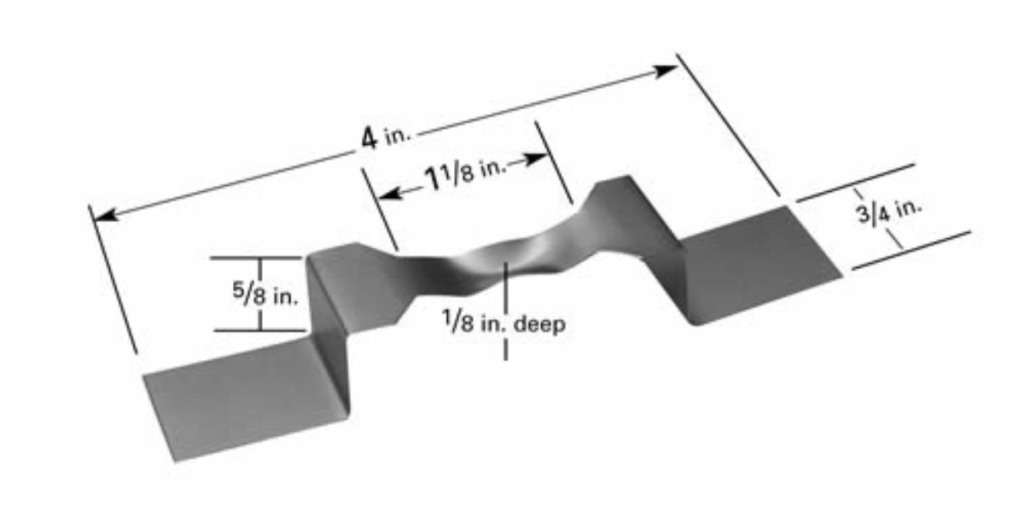

In the context of deposition systems using thermal evaporation, the parts used as resistive heaters can reach temperatures up to 2000°C. How thermal expansion is handled within the system is a contributing factor to the amount of cycles these parts can endure. By adding bends into the evaporation boat geometry, stresses at the mounting points of these parts can be alleviated.

Image: S1 Boat with bends to accommodate for thermal expansion

1.2. Thermal Stresses

Repeated cycles of heating and non-heating will introduce thermal stresses onto vacuum components. This can be minimized by ramping up temperatures and subsequently ramping down temperatures. For resistive heating elements, ramping up temperature and also ramping down temperatures for 5 minutes puts thermal shock into these parts.

2. Oxidation

Vacuum components should avoid long-term exposure to open atmospheric gases whenever possible to minimize oxidation, which contributes to contamination. Components such as heaters made from tungsten filament should not be operated outside of a vacuum environment. Parts such as molybdenum are prone to oxidation.

Thermal evaporation parts, such as boats or filaments, are best used upon receipt. For medium to long-term storage, controlled atmospheres or desiccants are preferred to limit any oxidation or contamination.

3. Corrosion

In vacuum processes involving high heat, parts can be damaged by corrosion or unwanted alloying between two surfaces. This is particularly relevant in thermal evaporation, where conduction of thermal energy enables evaporation material to form a gas phase and condense into a thin film.

3.1. Surface Area

Surface area is determinant of the amount of corrosion that occurs when dealing with molten material in processes like thermal evaporation. Overfilling a boat dimple with material increases the ratio of surface area contact, which also enables further alloying.

Minimizing early failure due to corrosion can be done by increasing boat capacity as to not overfill the evaporation area. Another method involves using tungsten wire mixture as sacrificial material, allowing the evaporation material to alloy with the mixture instead of the boat surface.

3.2. Thickness

Increased thickness (in the case of filament, wire diameters) helps extend lifetime of an evaporation source before it must be replaced. These resistively heated boats and filaments are more heavy-duty and thus require more power to run.

3.3. Alumina Coatings

Aluminum oxide (Al2O3) is a ceramic that exhibits inert properties with most molten materials. By coatings parts such as filaments, boats, or crucibles, the alumina layer inhibits corrosion. Coating processes for this material can be done on many different parts upon request.

Source Vacuum Components and Materials

R.D. Mathis Company works with high purity tungsten, tantalum, and molybdenum for vacuum applications. A wide range of vacuum-ready parts are available to meet performance and reliability needs across several different industries. With expertise in this type of manufacturing, please contact us for more information about vacuum solutions and custom fabrication to streamline your process.

We have several decades of experience with many forms of tungsten. For inquiries about quotes and manufacturing tungsten parts for your application, contact us with more details. Explore our selection today for tungsten components for ultra-high vacuum applications.