Vacuum System Performance: High-Current Electrical Components

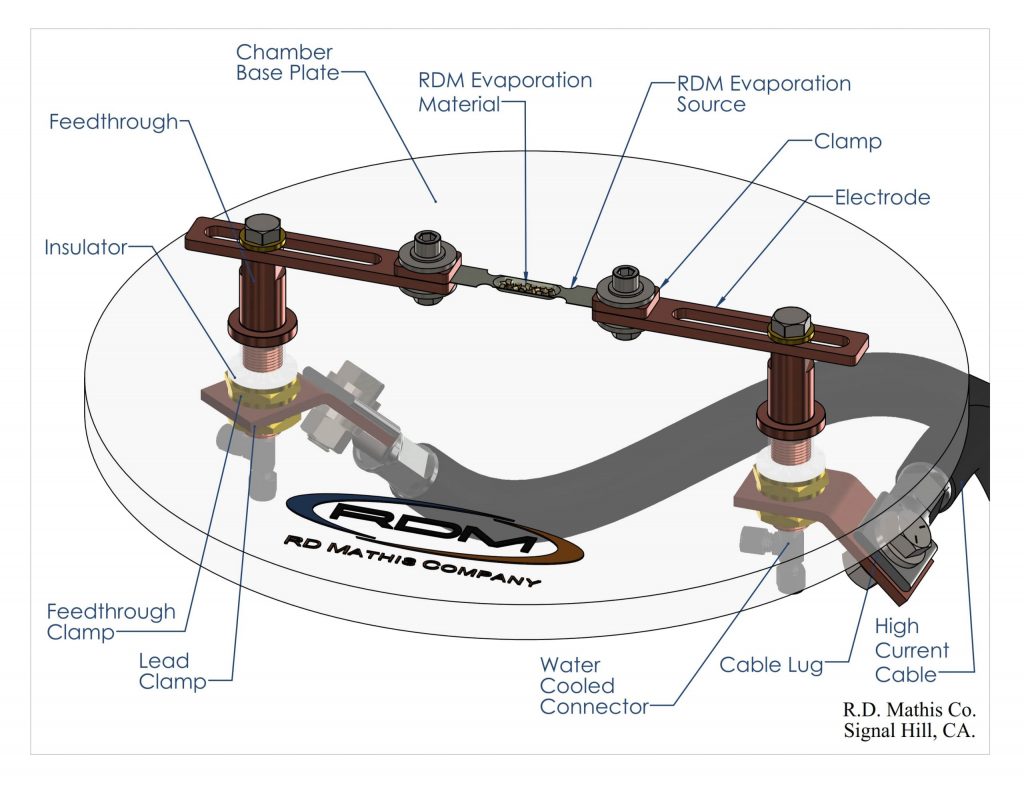

For thermal evaporators, depositions are conducted by running current through resistive thermal evaporation sources. Complex sources with heat shielding can require hundreds of amps. With this in mind, high-current electrical components such as lugs, feedthroughs, and cables must be able to safely deliver continuous power under these loads.

This review will go over the electrical system for delivering high current power into a vacuum chamber.

1. High-Current Low Voltage Power Supply

1.1. Overview

High-current power supplies provide the high current required to operate resistively heated evaporation sources. The energy outputted by these power supplies allows sources such as tungsten boats and filaments to reach temperatures of up to 2000°C. In the thermal evaporation process, temperature is dependent on the supplied current, which in turn controls the deposition rate.

1.2. Characteristics

Clear monitoring and resolution is important for fine-tuned control over deposition rates alongside a quartz crystal monitor (QCM) for real-time thickness readings. Unstable output from improperly selected power supplies can result in temperature fluctuations, tampering with the reproducibility of film thicknesses and uniformity.

Image: R.D. Mathis high-current power supplies, designed for specifically for thermal evaporation

2. High-Current Cables and Lugs

2.1. Overview of Cables

High-current cables serve as the pathway to transfer energy from the power supply to the vacuum chamber system. These components must minimize resistive losses and thermal buildup while maintaining durability and overall equipment performance.

2.2. Characteristics of Cables

Vacuum chamber system components may require adjustment in research and experimental set-ups. Available space in the system may limit room for cable management. In this case, flexible cables are recommended to save space when compared to rigid cables.

2.3. Lugs

High-current lugs provide a bridge between mechanical and electrical interfaces. Although overlooked, lugs can have a large effect on system performance. Improper installation can introduce contact resistance, instable voltages, or overheating. Ensure lugs are properly sized and installed for running depositions safely, smoothly, and at full capacity.

3. Feedthroughs

3.1. Overview

High-current feedthroughs must be able to transfer outside electrical power into a sealed environment without compromising integrity. Under high vacuum conditions, these components must resist thermal stresses and prevent leakage, which would otherwise cause contamination and potentially system damage.

3.2. Characteristics

To prevent overheating, higher amp feedthroughs use water-cooling to dissipate heat. Electrodes, attached to the feedthroughs, constitute the final elements of the electrical system.

Electrodes can also be designed for flexible chamber design. A slotted electrode provides an additional layer of operational adjustability for thermal evaporation systems.

High-Current Power Supplies, Cables, Lugs, and Feedthroughs

The optimization of electrical systems for vacuum deposition relies on efficient power transfer and integration. R.D. Mathis Company provides high-current components and customizable electrodes to support thermal evaporator equipment.

For maintenance of thin film coating processes, R.D. Mathis provides advanced evaporation materials and thermal evaporation boats and filaments for continued deposition needs. Contact us for information about any high-current electrical components or parts for conducting thermal evaporation.