Metal vs. Metal Oxide Sputtering Targets for Reactive Sputtering

Thin film deposition is a critical process in various industries, from electronics to optics and beyond. When it comes to sputtering, oxide coatings and other compound thin films plays a pivotal role in obtaining specific characteristics and performance of produced thin films.

Understanding the differences of these two similar target processes is important to see how composition affects the entire reactive sputtering coating process and end result.

Compound Materials For Thin Film Coatings

Many compounds can be deposited using physical vapor deposition processes, including nitride, carbide, and fluoride coatings to name a few. These thin films require stochiometric precision to ensure the ratio between elements is exact, leading to a coating with specific film properties.

Notably, oxide coatings are often used, encompassing materials such as zinc oxide, aluminum oxide, and titanium oxide. These targets find applications in diverse fields, including electronics, photovoltaics, and corrosion-resistant coatings. Oxide thin films offer versatility in tailoring specific material properties to meet the requirements of different applications.

1. Film Characteristics:

- Optical Properties: Oxides are often transparent and can exhibit variable refractive indices depending on the deposited film’s exact composition.

- Dielectric Properties: Useful for insulating layers and capacitor applications due to their electrical properties.

2. Applications:

- Displays: Oxide films are essential in display technologies like LCDs and OLEDs.

- Photovoltaics: Used in solar cell manufacturing for their transparency and conductivity.

Metal Sputtering Targets

One way of depositing metal oxide coatings is through reactive sputtering with pure metal sputtering targets, where oxygen is added as a reactive gas into the chamber. The pure metal and added oxygen react to form a metal oxide.

1. Material Purity and Composition:

- Purity: Metal sputtering targets are typically available in very high-purity grades (such as 99.999% purities), ensuring minimal contamination in thin film deposition processes.

- Composition: They consist of pure metals and can be deposited with precision. This combination offers flexibility in adjusting film properties by allowing the oxygen ratio to be altered.

2. Considerations:

- Process: Reactive sputtering needs precise control to ensure the film stoichiometry is correct, requiring monitoring and care of the oxygen flow in your vacuum chamber.

- Target Lifetime: Pure metal targets will last longer than compound targets.

Metal Oxide Sputtering Targets

Another way of depositing metal oxide coatings is by using a metal oxide target with the desired composition for your coating.

1. Composition and Structure:

- Oxide Formation: These targets are composed of metal oxides, where the specific oxygen content of the material has an influence on film properties such as transparency and conductivity.

- Stoichiometry: Control over stoichiometry (the ratio of metal to oxygen) is crucial for tailoring film characteristics.

2. Considerations:

- Reactive Sputtering: Oxide targets often require reactive sputtering techniques to control oxygen incorporation. However, the process is typically not as demanding when compared to using pure metal targets.

- Availability: Some oxides may have less availability, making it difficult to readily source specific compounds that you require.

Comparing metal and metal oxide sputtering targets shows several differences for varying applications. These should be kept in mind for thin film deposition and how an improper procedure can create unwanted thin film compositions.

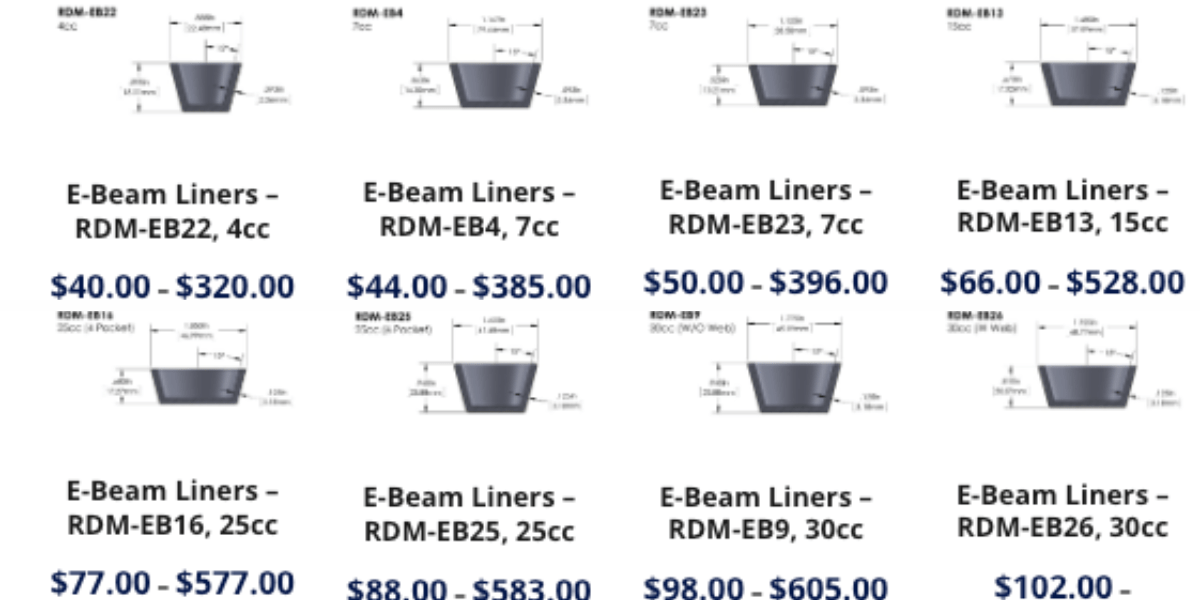

Shop R.D. Mathis Company

When navigating thin film deposition, the difference between metal and metal oxide sputtering targets is something you should keep in mind. Each type offers unique properties and advantages tailored to diverse applications in industries such as electronics, optics, and beyond.

For those seeking reliable and high-quality sputtering targets, R.D. Mathis Company emerges as a trusted partner. With our extensive expertise and commitment to precision manufacturing, we provide a comprehensive range of sputtering targets that meet stringent quality standards.

Shop our selection today.