Understanding the Chemical Resistance of a Boron Nitride Crucible

Boron nitride crucibles are becoming increasingly popular in various industries due to their exceptional chemical resistance. These crucibles, made from hexagonal boron nitride (h-BN), offer unique properties suitable for demanding applications, ensuring the purity and quality of processes in which they are used.

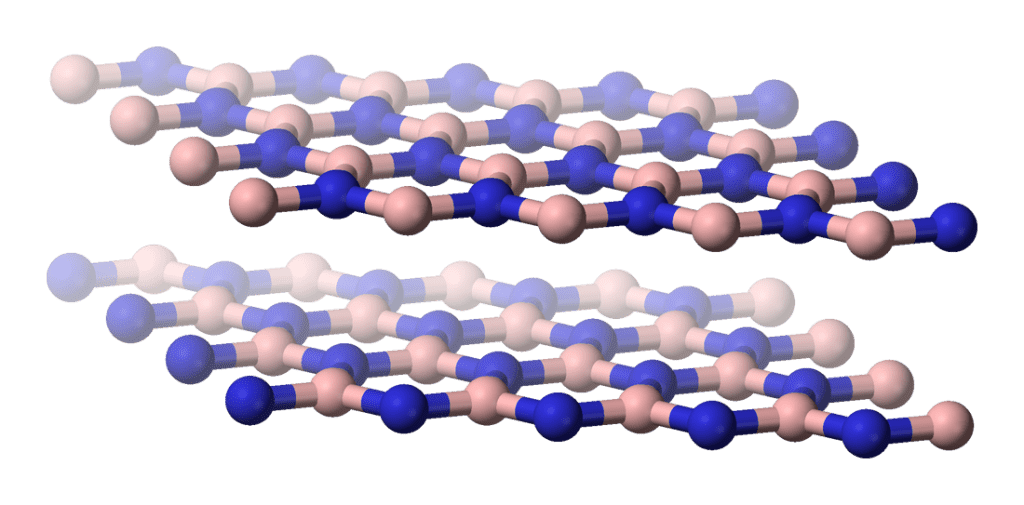

What is Boron Nitride?

Boron nitride (BN) is a synthetic material composed of boron and nitrogen. It exists in several crystalline forms, with hexagonal boron nitride (h-BN) being the most stable and commonly used form. h-BN is structurally similar to graphite, where boron and nitrogen atoms are arranged in hexagonal layers. This structure endows boron nitride with several remarkable properties, including high thermal conductivity, electrical insulation, and, most importantly, excellent chemical resistance.

The Chemical Resistance of a Boron Nitride Crucible

These properties of boron nitride make it applicable in many harsh environments, including elevated temperatures, corrosion, contamination-sensitive, and more. As a result, boron nitride has usage as a crucible material for thermal evaporated coatings as well. Let’s investigate the chemical resistance of boron nitride crucibles and why it’s an excellent choice for these various processes.

- Resistance to Acids and Alkalis

Boron nitride crucibles exhibit excellent resistance to acids and alkalis, even at high temperatures. This makes them suitable for processes involving highly corrosive chemicals, where traditional materials would fail. For instance, h-BN crucibles can withstand exposure to strong acids like hydrochloric acid (HCl) and sulfuric acid (H2SO4) without degrading or reacting.

- Inertness to Molten Metals

One of the standout features of boron nitride crucibles is their inertness to molten metals. Many metals, when heated to high temperatures, become highly reactive and can corrode or contaminate crucible materials. However, boron nitride remains stable and non-reactive, making it an ideal material for melting, casting, or thermally evaporating metals such as copper and especially aluminum.

- Resistance to Oxidation

Oxidation is a common problem in high-temperature applications. Materials exposed to oxygen at elevated temperatures can form oxides, compromising their integrity and performance. Boron nitride crucibles, however, have excellent oxidation resistance. They can operate in oxidative environments up to 1000°C, maintaining their structure and functionality.

- Stability in Reactive Atmospheres

Industries such as semiconductor manufacturing and materials research often require processes in reactive atmospheres like nitrogen, hydrogen, or ammonia. Boron nitride crucibles are chemically stable in these environments, ensuring the purity of the materials being processed and extending the lifespan of the crucibles.

Shop High-Quality Crucibles

Boron nitride crucibles offer unparalleled chemical resistance, making them indispensable in various high-temperature and corrosive applications. If you are looking for high-quality boron nitride crucibles, look no further than R.D. Mathis Company. We specialize in providing top-of-the-line crucibles that meet the rigorous demands of modern industry.

Visit our website to explore our selection for the best boron nitride crucibles on the market, compatible with our crucible heaters. For custom crucible sizes for your process, inquire with our technical team for a quote.