An Introduction to Thermal Evaporation Deposition in Thin Film Technology

Thin film technology plays a critical role across a wide range of industries, including semiconductor manufacturing, optical systems, and emerging applications such as flexible electronics. Among various deposition methods used in thin-film fabrication, thermal evaporation remains widely adopted technique due to its versatility and effectiveness.

1. Understanding Thermal Evaporation

Thermal evaporation deposition (thermal evaporation) is a deposition method used to deposit precise thin films of materials. In brief, this process involves vaporization of high purity materials and subsequent condensation onto a substrate to form a uniform thin film. The operating environment for this is carried out in a vacuum chamber to eliminate interference from residual atmospheric gases, which also maintains defect-free films.

This method is part of another broader field, known as physical vapor deposition (PVD), which uses physical movement of atoms without undergoing chemical reactions in the process.

2. Fundamental Principles of Thermal Evaporation

The fundamental principles behind thermal evaporation are as follows:

- 1. Vaporization: Resistive heating is used to heat target material (often in the form of wire, pellets, or pieces) until the vaporization temperature is reached.

- 2. Vacuum Transport: The material turns into a vapor (gaseous) state, travelling in a line-of-sight trajectory. Vacuum conditions allow the vapor atoms to travel without colliding with residual gases.

- 3. Condensation: Upon reaching the cooler substrate surface, vaporized target material condenses into solid form. The following result is a thin film of the material with precise thickness and properties.

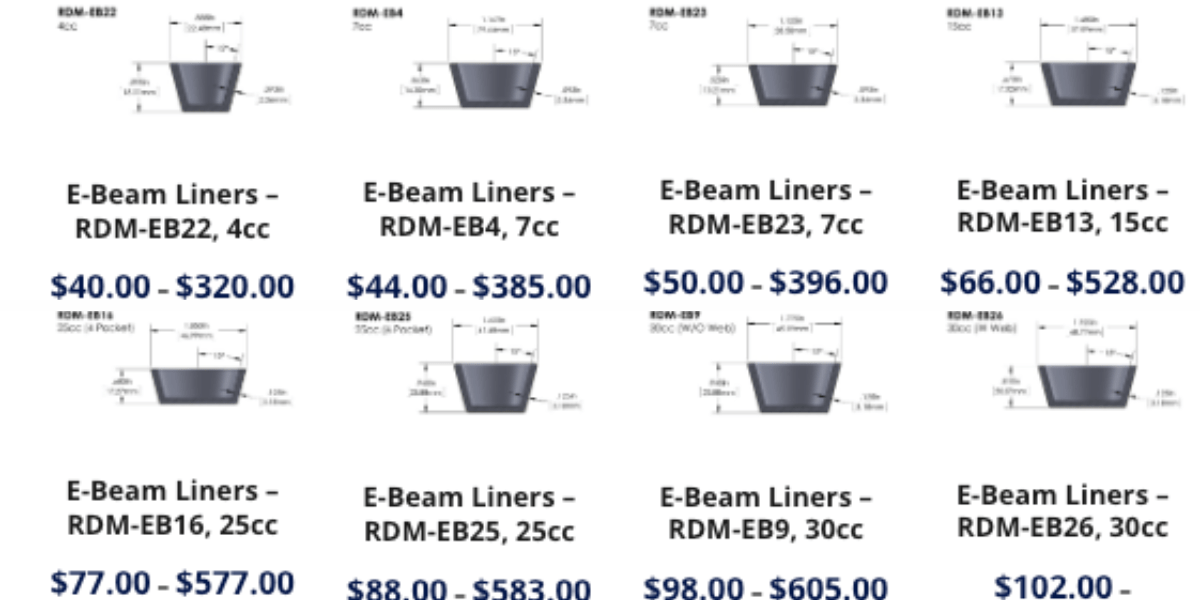

3. Materials Used

A wide range of materials can be used in thermal evaporation, such as metals, alloys, and even some organic compounds. Generally, commonly used materials include aluminum, gold, silver, and various dielectric materials. The choice of material depends on the particular application and the properties required for the thin film.

Thermal evaporation can only deposit metals: False!

Contrary to common misconception, compound materials such as silicon monoxide, titanium oxide, or zinc sulphide are used in various different coating applications. For instance, magnesium fluoride is often used as an anti-reflective coating.

4. Applications

4.1. Semiconductor Industry

Thermal evaporation is widely used in semiconductor manufacturing to deposit metals such as copper, as well as dielectric layers like silicon dioxide (SiO₂), onto integrated circuits. In semiconductor applications, coating materials are carefully chosen based on their electrical characteristics and their compatibility with the underlying substrate.

4.2. Thin Film Optics

Thin film coatings applied to optical components, such as lenses and mirrors, benefit the ability to control properties like reflectivity. Silicon dioxide is used in optical applications as an anti-reflective film for high-precision applications, including telescopes or other advanced instruments.

4.3. Photovoltaics

In solar cell fabrication, thermal evaporation is commonly employed to deposit thin films of semiconductor materials such as silicon and cadmium telluride. Modern PVD technologies allow these coatings to be accurately applied to silicon wafers while minimizing stresses, preserving substrate integrity.

4.4. OLED Displays

Organic light-emitting diode (OLED) displays benefit from the precise deposition of organic materials using thermal evaporation. Overall, this process facilitates high efficiency, color accuracy, and reliable device performance, which are all critical for display applications.

4.5. Sensors

Thin film sensors for various applications, such as gas detection or biosensing, are produced using thermal evaporation. By enabling uniform and high-quality film deposition, this technique ensures consistent sensor sensitivity, accuracy, and reproducibility.

5. Advantages

- 1. High purity: The vaporized material is typically of high purity, leading to pure and contaminant-free thin films. Unwanted particulates in the atmosphere are removed during the pumpdown of the vacuum chamber.

- 2. Controlled thickness: Thermal evaporation allows precise control over film thicknesses, making it suitable for sensitive applications requiring nanoscale precision.

- 3. Uniform coatings: The method produces uniform and even coatings across large areas.

- 4. Versatility: It can be used for a wide range of materials, both conductive and insulating.

- 5. Cost-effective: Thermal evaporation is often more cost-effective than other thin film deposition techniques.

Media: Thermal evaporation, Inmodus, licensed under CC BY-SA 4.0

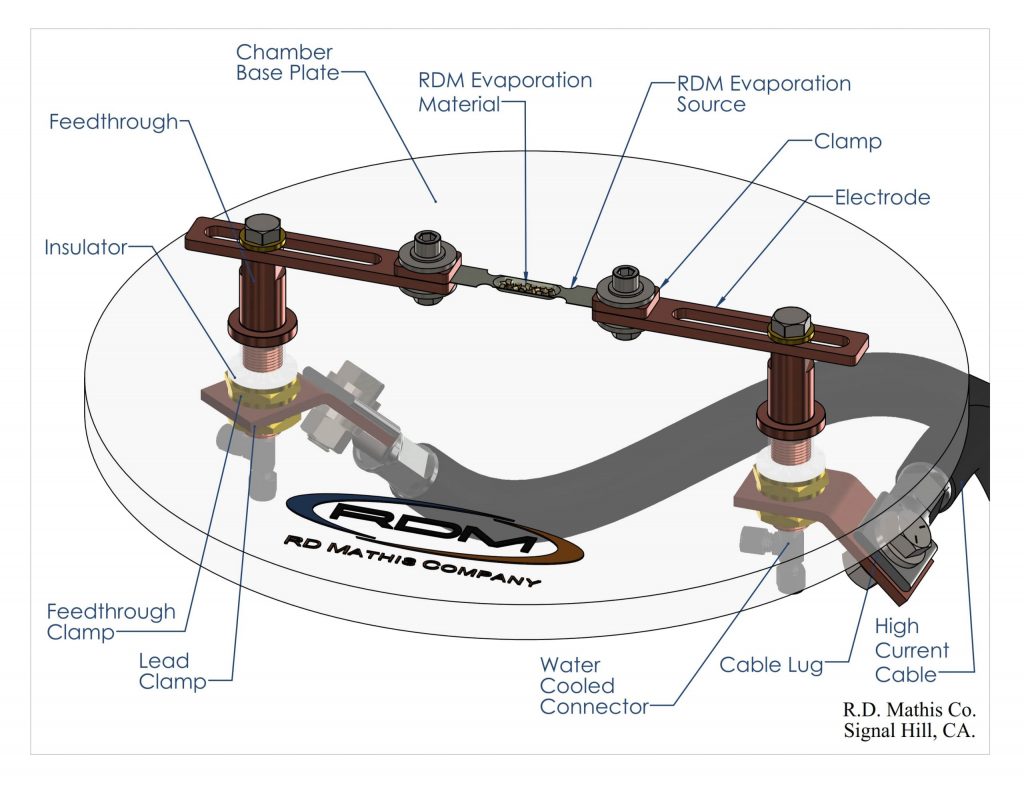

Thermal Evaporation Deposition and R.D. Mathis Company

R.D. Mathis Company is a long-standing manufacturer of thin-film deposition equipment, providing solutions for research and industrial applications that require precise and controlled thin-film deposition. With ongoing advancements in thermal evaporation technology, the company consequently continues to support the advancement and optimization of thin-film processes across a variety of applications.

Visit our website to learn more.