0

You have 0 items in your cart

RD Mathis Company Technical Library Publications

info@rdmathis.com | www.rdmathis.com

Evaporation of metals from crucibles, open boats, wire coils or filaments is often plagued with erratic eruptions, particularly if fast evaporation rates are used. These eruptions are caused by boiling of the metal as gas is released from the molten metal, and are of sufficient force to carry globules of metal to the target surface. These globules are often small enough that they go unnoticed.

Fortunately, in some cases, they have no adverse effects on film performance. However, in most electronic and magnetic applications, the presence of such defects is highly undesirable. The effects of such defects on film-type capacitors, for example, are well known. Recent discussions of this subject by W. C. Vergara et al[1] of the Bendix Corporation have recently been published. Their findings have been confirmed by work done at Halex, Inc., Autonetics and other concerns.

One method that has been used to circumvent the effects of eruptions is to use source-to-substrate distances great enough and evaporation rates slow enough that the globules never reach the target surface. Large evaporation charges, considerably longer evaporation times, and lower pressures are required for achieving films of the desired characteristics using this method. This is often considered not practical.

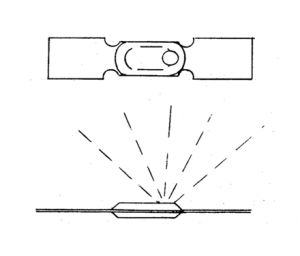

An alternate approach is to prevent the globules from leaving the source in the first place, which can be accomplished in a number of ways. A simple design that has proven effective is described in Figure 1. As noted in the sketch, the bottom of the evaporator is a dimpled boat. The cover, likewise, is dimpled in the same manner such that the two mating surfaces are straight and will close reasonably well. Both boat and cover are notched at the ends of the dimple to provide a hot spot at these points, and limit the wicking of the molten metal between the cover and the boat. As noted in the sketch, the orifice is off-center, well toward one end of the boat. The charge is placed in the boat through this orifice and pushed back toward the opposite end of the boat.

Figure 1

Covered Source Metal

During melting and evaporation, the metal vapor finds its way to and out of the orifice. Because of the offset hole or orifice, the target placed above the evaporator does not see the molten metal source. However, the vapor emanates from the orifice upward in a wide cone with distribution very nearly that produced by point source, as shown in Figure 2.

Figure 2

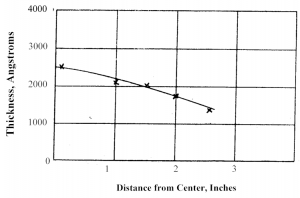

Thickness Distribution from the Covered Source at a Source-to-Substrate Distance of 4 Inches

The data for the graph was obtained at a close distance of 4 inches between the source and the substrate. A charge of 130 milligrams produced film thicknesses as shown in the evaporation time of 20 seconds.

Capacitors were fabricated by using this type of source* to produce the electrodes. A baffled box source* was used to deposit the silicon oxide dielectric. Copper was used for the bottom electrode and aluminum for the top.

Three notable results were observed. Microscopic examination of the surface of the deposited electrodes showed no evidence of surface defects or globules. Shorted capacitors were almost non-existent (for example, less than 2% in several hundred capacitors made during the experiment). Also, voltage breakdown characteristics were markedly improved. Breakdown at voltages up to 100 volts was unknown. Higher voltages were not tested.

*The covered boat source and the baffled box source used in these studies were fabricated by the RD Mathis Co., Long Beach, California.

This type of covered evaporation source has proven to be an effective means of producing metal films with defect-free surfaces. The design is simple, and the boat is easy to load and keep clean. When used for evaporating copper, a covered boat of this design has been used for well over 50 evaporations. In the case of aluminum evaporation, the life is limited by the alloying of the aluminum with the tungsten boat. This was minimized by adding short lengths of tungsten wire in the boat with the aluminum metal. By this means, as many as six evaporations were made with a single boat.

Author

Earl Olson

HALEX, Inc.

139 Maryland Avenue

El Segundo, CA 90245

Distributed By

RD Mathis Company

2840 Gundry Ave Signal Hill CA 90755

Phone: (562) 426-7049 | Fax: (562) 595-0907

1) W. C. Vergara Et al Rev. Sci. Instruments, 34 (May.1963)

2) Holland, L. and Stekelmacher, W. Vacuum 2 (1952) 346