0

You have 0 items in your cart

Thermal evaporation has the benefit of flexible source geometries. This can be used to physically constrain the vapor stream, allowing you to control it.

Filtering is done by forcing vapor through a system of baffles. This removes particulates in the vapor stream, preventing formation of pinhole defects.

Directional control can also be applied to change the angle of vapor streams. The vapor exits a chimney with a specified orientation. Directional sources are typically used for subliming materials.

Vapor control can be done with standard parts or with modified and customized parts to fit your process needs.

Since chromium sublimes when evaporated at low pressures, lumps or granular chrome exhibit erratic activity during evaporation cycles, causing the deposition to lack desired uniformity.

Because of issues with thermal efficiency when using chromium chips or pellets, imperfections such as spalling and pinholes occur in your thin film coating.

These chrome-plated sources present a uniform, cylindrical surface of known dimensions, so that evaporation and the consequent deposition occur at controllable, uniform rates.

This makes these rods excellent pre-loaded evaporation sources for vacuum depositing chromium films.

Some major advantages of these rods include:

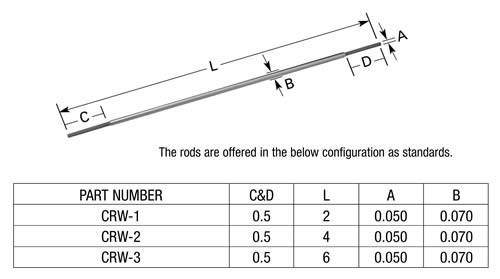

Part Number CRW

Chromium plated tungsten rods are typically available in 2″, 4″, and 6″ lengths. Reference above diagram for more details and specs.

Do you have any comments or concerns you want to share with us?

Please give us a call for further questions about The Evaporator.

Phone: (562) 426-7049

Email: info@rdmathis.com

Website: rdmathis.com

| National Aeronautics and Space Administration |

(Image: NASA)

Reducing dust accumulation on any surface is key for lunar missions as dust can damage or impair the performance of everything.

| Physics World |

(Image: Yongxi Li, University of Michigan)

Carbon-based organic photovoltaics (OPVs) may be much better than previously thought at withstanding the high-energy radiation and sub-atomic particle bombardments.

| SLAC National Accelerator Laboratory |

(Image: RubinObs/NOIRLab/NSF/AURA)

The first reflective coating was applied to Vera C. Rubin Observatory’s 8.4-meter combined primary/tertiary mirror using the observatory’s onsite coating chamber.

Nashville, Tennessee | May 20-21, 2025

Gaylord Opryland Resort & Convention Center

Booth: 919 | Website

Charlotte, NC | Sept 21-26, 2025

Charlotte Convention Center