0

You have 0 items in your cart

An advantage that thermal evaporation has is flexible source geometry, which can be used to physically constrain and control vapor.

Filtering is done by forcing vapor through a system of baffles. This removes particulates in the vapor stream, preventing the formation of pinhole defects.

Directional control can also be applied to change the angle of vapor streams. The vapor exits a chimney with a specified orientation. Directional sources are typically used for subliming materials.

Gold thin films are used in many industries, primarily due to its excellent conductivity and optical properties.

As an evaporation material, boats, baskets, crucibles, and filament sources are all common ways to deposit gold.

However, at elevated temperatures, gold has two main issues:

1. Gold becomes corrosive when molten, eventually corroding boats and filaments.

2. Migration occurs, causing gold to creep to cooler spots of the boat source or creep towards where it is mounted.

Gold evaporation can be optimized through alumina-coated tungsten sources. This combination of tungsten alongside alumina coating maximizes lifetime while minimizing precious metal loss.

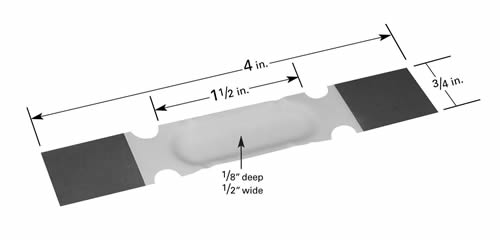

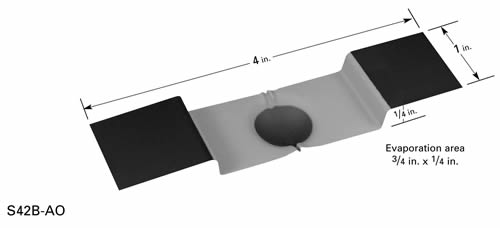

Full alumina coating prevents any gold from wetting to the boat. On the other hand, a barrier style (pictured below) maintains direct thermal contact while still keeping gold from wetting out.

Alumina coatings can be flexible and applied to various other parts, not just boat sources. Box sources, crucibles, and even baskets can be alumina-coated.

Do you have any comments or concerns you want to share with us?

Please give us a call for further questions about The Evaporator.

Phone: (562) 426-7049

Email: info@rdmathis.com

Website: rdmathis.com

| Fraunhofer ISE |

(Image: Fraunhofer ISE)

In a “hybrid route” combining evaporation and blade-coating to deposit perovskite solar cells on silicon bottom cells, they produced tandem solar cells with efficiencies approaching 28 percent.

| Nature Communications |

(Image: Nature Communications)

Researchers at Nanjing Tech University (NanjingTech) and South China University of Technology have demonstrate a layer-by-layer (LBL) thermal-evaporation strategy to fabricate high-quality perovskite-emitting films with tunable emission wavelengths.

| pv magazine |

(Image: University of Oxford Press Office)

A team of scientists in the United States has studied how a perovskite solar cell degrades when under reverse bias conditions.

Fremont, CA | Feb 26, 2026

Fremont Marriott Silicon Valley