0

You have 0 items in your cart

The R.D. Mathis Company has published a new catalog, featuring more products for your evaporation needs. This features a new cover design, along with some new part releases.

Call us at: 526-426-7049

Email at: catalogs@rdmathis.com

Download at: rdmathis.com/technical-library/

Check out boats like our S52 & S53, bent lead configuration on the S8E dimple boat and deep drawn S9G boat. Inquire about specialized solutions like z-coiled filaments, cool lip crucibles and tungsten wire mixture.

Over time, boats will need to be replaced as they go through cycles of extreme heat and cooling down. However, some materials, when molten, can alloy or corrode through metals.

Improper boat selection can lead to source failure, causing unnecessary inefficiencies in your thin film coating process.

Here are some considerations to take into account when selecting your evaporation boat sources:

1. Take into account material thickness. Thicker material will be able to withstand more corrosion when compared to thinner boats.

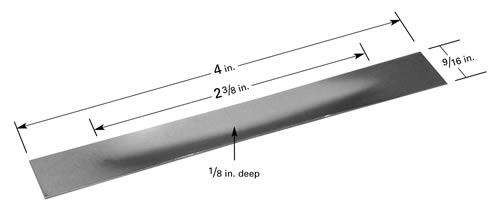

Pictured is the S47 boat, available in thicknesses up to .020”

2. Consider adding tungsten wire mixture to the boat. Tungsten mix allows material to wet to it, preventing migration or splattering. This mix also acts as sacrificial clippings against corrosion.

Part # WWMIX

3. Utilize aluminum oxide when applicable. Alumina coatings are chemically inert to most materials, protecting refractory boats from reacting with evaporation materials.

Alumina can be applied to a wide variety of boat sources, like the S3.

Do you have any comments or concerns you want to share with us?

Please give us a call for further questions about The Evaporator.

Phone: (562) 426-7049

Email: info@rdmathis.com

Website: rdmathis.com

| Tech Xplore |

(Image: Nature Energy, 2024)

Researchers at University of Oxford, the Faraday Institution, Nissan Motor Co. Ltd. and other research institutes recently carried out a study exploring the different technologies and processes.

| Oak Ridge National Laboratory |

(Image: Chris Rouleau ORNL, U.S. Dept. of Energy)

A novel tool developed at Oak Ridge National Laboratory that leverages those technologies has demonstrated that AI can influence materials synthesis and conduct associated experiments without human supervision.

| Max Planck Society |

(Image: Max-Planck-Institut for Polymer Research)

Scientists led by Denis Andrienko of the Max Planck Institute for Polymer Research and Falk May from Display Solutions at Merck have now developed a simulation method.

Fremont, CA | February 27, 2025

Fremont Marriott Silicon Valley, 46100 Landing Pkwy

Anaheim, California | March 16-21, 2025

Anaheim Convention Center, Anaheim Marriott, and Hilton Anaheim

Booth: 655 | Website

Nashville, Tennessee | May 20-21, 2025

Gaylord Opryland Resort & Convention Center

Booth: 919 | Website