0

You have 0 items in your cart

For complex coating applications or extremely high temperature materials, sputter deposition’s strengths can complement other deposition methods such as thermal evaporation.

Typical sizes of sputtering targets come in 2″, 3″, or 4″ diameters with 0.25″ thickness. Our standard available selection include common elemental metal targets. Some notable materials include aluminum, gold, and niobium sputtering targets.

For custom sizes and thicknesses, including millimeter sputtering targets, or compound targets, such as titanium nitride, let us know! Please contact us with your needs for specialty sputtering targets and we can see what we can do.

Copper is a well-known material for its electrical conductivity, making it used in applications such as semiconductors.

Thermal evaporation of copper is done using molybdenum boats, coming in many styles for different configurations.

Since thermal evaporation uses resistance heating to deposit material, copper’s conductive properties can affect the deposition.

However, this can be accounted for with aluminum oxide coating, for example: Part# S21-AO-Mo.

By applying this alumina to the full region of the evaporation area, current flowing through the source is unaffected by the copper evaporation material.

If higher capacity requirements are necessary for copper deposition, deeper areas of folded boats (FBs) may be needed. Upon request, these can also be coated in alumina to help deposit copper.

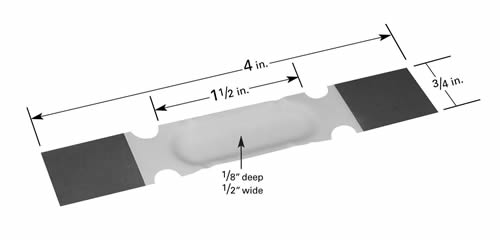

Folded Boat styles

Questions about copper depositions or any other material? Email our team at tech@rdmathis.com. Let us know if our selection can help you out.

Do you have any comments or concerns you want to share with us?

Please give us a call for further questions about The Evaporator.

Phone: (562) 426-7049

Email: info@rdmathis.com

Website: rdmathis.com

| IEEE Spectrum |

(Image: ISTOCK)

While lithium-ion batteries have become a global standard, the need for batteries with higher energy densities is prompting more research into other promising battery architectures.

| University of Osaka |

(Image: Applied Physics Letters, 2025)

A study published in Applied Physics Letters, led by researchers from SANKEN at The University of Osaka, has revealed a technique for recovering magnetism in a degraded spintronics device.

| Pennsylvania State University |

(Image: Jon-Paul Maria)

Now, turning a non-ferroelectric material into one may be possible simply by stacking it with another ferroelectric material, according to a team led by scientists from Penn State.

Boston, MA | Nov 30-Dec 5, 2025

Hynes Convention Center

Booth: TBA | Website

Fremont, CA | Feb 26, 2026

Fremont Marriott Silicon Valley