0

You have 0 items in your cart

Evaporants for deposition come in multiple forms. Small pellets or granular pieces are common, allowing uniform heating.

Powders are another option, but can introduce spitting. By adding baffles, forcing vapor to move across indirect paths, certain source designs filter out particulates.

For thermal evaporation using filament sources, wire, clip, or cane materials are used. When the evaporant melts, it wets to the filament’s surface.

Sputtering targets, starter slugs, and specialty alloys are available, up to 5N purity. Contact us for more information about our wide range of materials or customization.

In thermal evaporation processes, chromium is unlike many other materials due to how it sublimes at low pressures.

If approached using small pellet material or other similar sizes, chromium acts erratically which affects film uniformity. To best approach deposition, it must be very controllable.

Rather than using a boat or a crucible source for chromium, plated tungsten rods provide unique advantages.

1. With preloaded chrome, this makes depositions more user-friendly, repeatable, and consistent.

2. The cylindrical surface with known dimensions provides uniformity.

3. Low power is required, which also leads to a small degree of heat radiation to the vacuum chamber.

For deposition processes, these chrome rods allow controllable film thicknesses that are high purity without any pinhole defects.

These are tried and proven method for chromium coatings in both research applications and also for high volume production use.

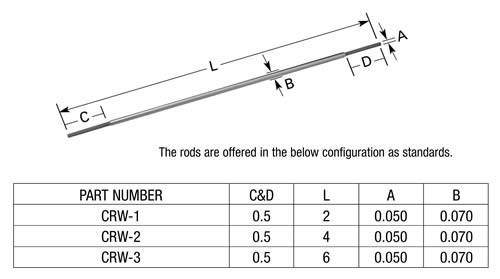

Standard sizes for these chromium-plated tungsten rods (CRWS) are available in 2 inch, 4 inch, and 6 inch lengths.

For inquiries about chromium deposition using this product, please email us at tech@rdmathis.com. Otherwise, see our product page here:

Do you have any comments or concerns you want to share with us? Please give us a call for further questions about The Evaporator.

Phone: (562) 426-7049

Email: info@rdmathis.com

Website: rdmathis.com

| Electro Optics |

(Image: U.S. Food and Drug Administration)

There has also been a resurgence in thermal evaporation techniques, according to Chris Cook, principal engineer at Edmund Optics. Most precision optics are still coated with evaporation techniques.

| National Aeronautics and Space Administration |

(Image: NASA)

Innovators at NASA Goddard Space Flight Center have developed an advanced method to produce Al mirrors protected with a LiF overcoat using a novel room-temperature reactive Physical Vapor Deposition (rPVD) process.

| National Renewable Energy Laboratory |

(Image: Advanced Photonics Nexus 2025)

As technology advances, photonic systems are gaining ground over traditional electronics, using light to transmit and process information more efficiently. One such optical system is laser beam scanning (LBS).

Boston, MA | Nov 30-Dec 5, 2025

Hynes Convention Center

Fremont, CA | Feb 26, 2026

Fremont Marriott Silicon Valley