0

You have 0 items in your cart

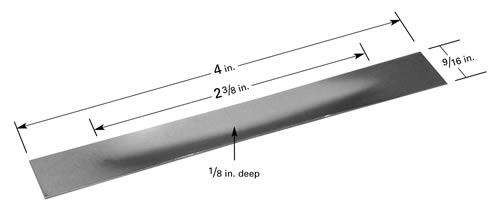

At their core, evaporation boats are made to hold and heat up material. These come with varying dimples or troughs, depending on the capacity needed.

Other design features can enhance the deposition process. Bends provide relief from thermal expansion. Notches allow heat to be focused into specific areas. These unique geometries allow flexibility for different processes.

With short lead times and affordable prices due to flexible tooling, we have offered many specialized boats to customers.

Our selection of boats is easily adaptable to different lengths, bends & other features needed. Let us know how we can help.

Thin films of aluminum are widely used for numerous applications, such as optical coatings making use of its reflective properties.

Although aluminum does not have problems like spitting, keep in mind the following when depositing aluminum:

To optimize aluminum deposition, choose tungsten as the boat or coil material with large thicknesses, such as an S47 boat.

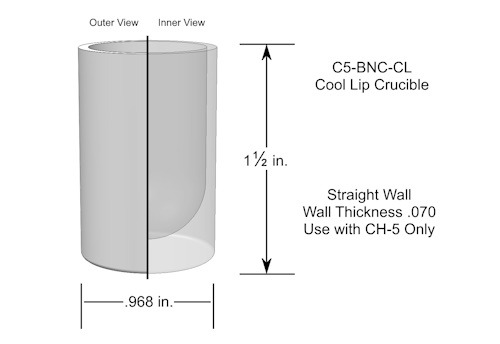

For crucible heating, boron nitride composite (BNC) is an excellent choice to prevent the molten aluminum from wetting to the side walls.

Cool lip style crucibles are particularly designed for aluminum evaporation, with extended walls inhibiting migration.

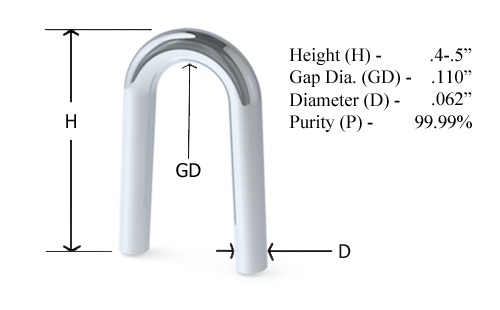

This aluminum evaporation material comes in many forms, including pellets, wire, and also cane or clip shapes.

For more information about aluminum materials and aluminum thermal evaporation, feel free to email or call us.

Do you have any comments or concerns you want to share with us?

Please give us a call for further questions about The Evaporator.

Phone: (562) 426-7049

Email: info@rdmathis.com

Website: rdmathis.com

| University of Florida |

(Image: Acta Crystallographica Section A, 2025)

Research led by University of Florida engineering professor Megan Butala enables a novel way to look at the atomic structure of thin films on single-crystal substrates.

| University of Tokyo |

(Image: Kazunori Nishio, Science Tokyo)

Using dLab, his team demonstrated the autonomous synthesis of lithium-ion positive-electrode thin films and their structural evaluation via X-ray diffraction pattern measurements.

| National Renewable Energy Laboratory |

(Image: National Renewable Energy Laboratory)

A compelling reason to find ways to produce stable thin films with layered, nearly two-dimensional structures is that many of them have unusual chemical, semiconducting, or quantum properties.

Charlotte, NC | Sept 21-26, 2025

Charlotte Convention Center

Booth: TBA | Website

Boston, MA | Nov 30-Dec 5, 2025

Hynes Convention Center

Booth: TBA | Website