0

You have 0 items in your cart

Applications

Chromium coatings are known for its resistance to corrosion and shiny finish. However, chromium can be a difficult for thermal evaporation due to how it sublimes at low pressures. To have successful pinhole-free coatings, controlled heating is required. These rods provide a reliable alternative to pellets.

Material Cost-Effectiveness

Chrome-plated rods (CRWs for short) are tungsten rods that are preloaded with chromium across its length for user-friendliness and repeatability. Cylindrical geometry and known dimensions enables uniform heating. These also require low power, reducing heat radiation to the vacuum chamber.

The Evaporator

1. Toxic artillery: Paradigm Shift Technologies on chrome plating

2. Technical Tip – Silver Evaporation

3. Solar perovskites power U.S. Army deployable microgrid demonstration

| Paradigm Shift Technologies |

Electromagnetically enhanced Physical Vapour Deposition (EPVD) is an alternative to chrome plating in the production of artillery barrels that found its origins in coating petrochemical tubes for use in high pressure, high temperature conditions.

Chrome plating, which has been used on artillery since 1922, extends the lifetime of the barrel by 50-100%, potentially doubling the number of shells fired before replacement. Still, thermal impact leads to erosion, fatigue, and failure.

Silver Evaporation – How to Evaporate Silver

Silver Evaporation – How to Evaporate SilverThin films of silver are used in various applications: such as optical, semiconductor, and sensor technology. For example, silver electrodes see use in solar cells.

Compared to other materials used in thermal evaporation, silver deposits well due to being non-corrosive at high temperatures. Silver is easily deposited from a variety of boat styles. Molybdenum and tantalum are recommended boat materials for this process.

Optimizations for depositing thin films of silver will vary depending on process variables such as desired capacity, mounting bracket set-up, and available power source.

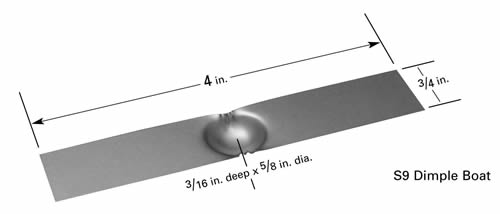

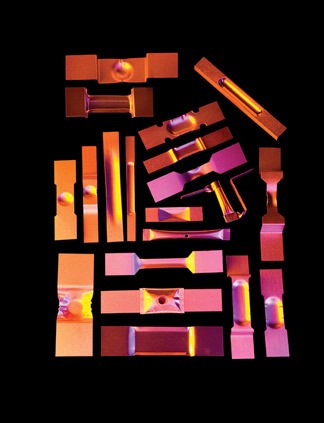

Boats come available in many designs, flexible for specific needs. Different dimples/recesses (round vs. elongated) or step geometry to absorb thermal expansion are design elements that can form consistent procedure for depositing silver.

| Swift Solar |

Solar perovskites have advanced rapidly in both efficiency and durability as developers compete fiercely to commercialize their products.

Swift Solar internally developed a novel vapor deposition technology for its manufacturing process. The new method is a non-batch process that solves two problems associated with the use of established vapor processing in perovskite material manufacturing – the slow speed of deposition and the non-continuous nature of batch processing.

Fremont, CA | Feb 26, 2026

Fremont Marriott Silicon Valley

We appreciate your honest feedback and would like to see what our readers have to say about our company, service, and products. Thank you for reading The Evaporator.

Let us know how we can improve our customer experience through social media or email.