0

You have 0 items in your cart

Applications

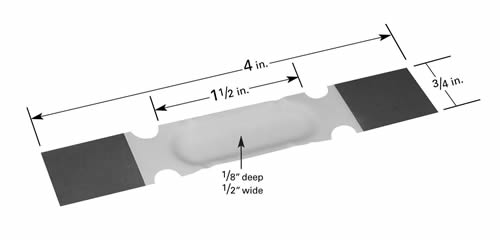

These types of thermal evaporation sources measure under 2 inches and enable coating applications with limited power systems at more affordable prices. Because of their size, micro-electronic sources require less power to get up to temperature.

Material Cost-Effectiveness

Coating methods such as e-beam or sputtering require a minimum fill level or utilize expensive targets, discouraging small-scale applications.

Micro-electronic sources work well in cases where only small amounts of evaporation material is needed. This makes them particularly useful for one-off coatings or other small batch applications.

The Evaporator

1. World-first solar thermal demonstrator targets net zero breakthrough for industry and agriculture

2. Technical Tip – Maximizing Boat Lifetime

3. Less is more: Efficient hydrogen production with less precious metals

| University of South Australia |

Leveraging more than a decade of research into durable, weather-resistant reflective coatings, the project – funded by the Federal Government’s Australia’s Economic Accelerator (AEA) Ignite program – will fabricate and install a novel, two-module CST demonstrator incorporating the mirrors.

The panels incorporate a multilayer aluminium-silica reflective coating developed by UniSA’s Future Industries Institute, applied via a physical vapour deposition to ensure durability and optimal solar reflectivity. Dr Llusca Jane says the AEA funding is critical to the project’s success.

Maximizing Boat Lifetime

Maximizing Boat LifetimeOver time, boats will need to be replaced as they go through cycles of extreme heat and cooling down. However, some materials, when molten, can alloy or corrode through metals.

Improper boat selection can lead to source failure, causing unnecessary inefficiencies in your thin film coating process.

| University of Twente |

In a step towards sustainable energy, a team of researchers at the University of Twente led by Dr. Marco Altomare has demonstrated a new method to reduce the use of precious metals such as platinum in green hydrogen production without sacrificing performance.

Polymer electrolyte membrane (PEM) water electrolyzers and fuel cells use precious metal catalysts such as platinum and iridium to make hydrogen production and conversion as efficient as possible. However, these catalysts are expensive and scarce and thus limit large-scale development of hydrogen technologies.

Fremont, CA | Feb 26, 2026

Fremont Marriott Silicon Valley

We appreciate your honest feedback and would like to see what our readers have to say about our company, service, and products. Thank you for reading The Evaporator.

Let us know how we can improve our customer experience through social media or email.