An Overview of the Purification of Inert Gases

Inert gases, such as nitrogen, argon, helium, and neon, are widely used in advanced manufacturing and analytical science processes. However, even trace impurities such as moisture, oxygen, hydrocarbons can affect performance. Inert gases must undergo a purification process to meet stringent requirements, employing the use of an inert gas purifier.

1. Inert Gases

1.1. Background

Inert gases, also known as noble gases, occupy Group 18 of the periodic table and exhibit inertness due to a stable electron configuration. These gases and their lack of reactivity makes them ideal for applications where other gases might cause unwanted chemical reactions. Common inert gases include nitrogen (N2), argon (Ar), helium (He), krypton (Kr), xenon (Xe), and neon (Ne).

2. The Need for Inert Gas Purification

2.1. Inert Gas Sources

While inert gases are commercially available, they often contain impurities in various forms, such as moisture, hydrocarbons, oxygen and other reactive elements. These impurities can have adverse effects on specific applications.

For instance, in gas chromatography or semiconductor manufacturing, even trace amounts of impurities at a parts-per-million level can result in measurement inaccuracies or compromised wafers and component performance. High‑purity inert gas environments are therefore critical to ensuring reproducibility and reliability in research and production settings.

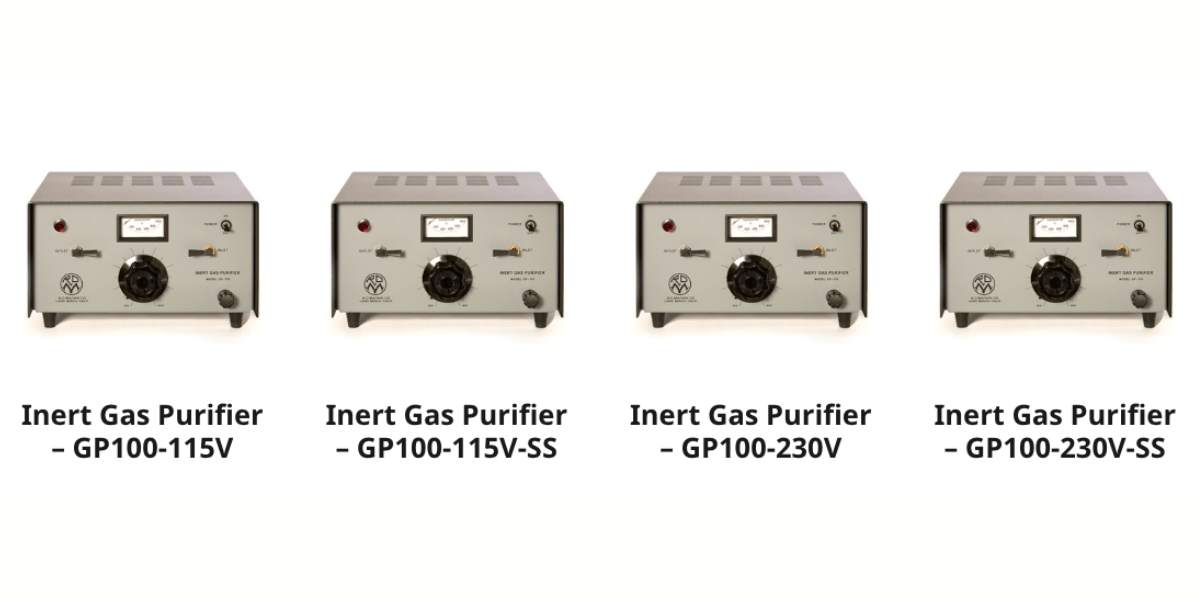

Image: R.D. Mathis Company Inert Gas Purifier

3. Gas Purification Methods

An inert gas purifier can be selected based on purification technique, which vary in cost, efficiency, and suitability for specific applications.

3.1. Cryogenic Distillation

This method utilizes the differences in boiling points to separate inert gas from contaminants. By cooling inert gas to temperatures close to its boiling point, impurities can be selectively liquefied and separated. Repeating this process can increase inert gas purities but consumes large amounts of power and is more suitable for larger-scale operations.

3.2. Pressure Swing Adsorption (PSA)

PSA uses adsorbent media that bind to impurities found in the inert gas mixture based on pressurization. In the first stage, adsorbent selectively binds to contaminant gases in high pressure conditions. The next phase involves depressurization to release the contaminant gases, regenerating the adsorbent media.

Nitrogen purification is often done using PSA. For other inert gases, such as those often used in vacuum deposition systems (Ar, Ne, or Kr), adsorbent media can be limited or ineffective.

3.3. Membrane Separation

Membrane systems use differential permeability to separate contaminant gases based on molecular size. Smaller molecules pass through the membrane, leaving impurities behind. However, maximum purities are limited with this approach, unable to reach ultra-high inert gas purities in most cases.

3.4. Chemisorption

Chemisorption uses reactive materials that form strong chemical bonds with impurity gases. These materials are known as “getters”, and include materials such as titanium or zirconium. Since inert gases do not react with the getter element, they can be purified to very high levels using this method.

For further reading, see the published paper on inert gas purification in Technical Papers in the technical library.

4. Benefits of High-Purity Inert Gases

4.1. Examples

An inert gas purifier is a useful appliance in certain sensitive applications. High purity inert gases provide benefits in several varying cases, including:

- Contamination-free environments: Thin film depositions are conducted in vacuum and are sensitive to contaminants. To ensure coatings for sputtering meet performance requirements, the argon gas used must be extremely pure.

- Process monitoring: The extra level of purity provides accurate testing in controlled environment experiments and gas chromatography.

- Quality control: Laser cutting specialty materials benefit from inert gas purity to allow for consistently smoother cuts and preventing trace oxidation formation.

Some examples of industries that require inert gas purification include defect-free semiconductor manufacturing, nitrogen purging in pharmaceutical applications, and gloveboxes using inert gases to displace oxygen for cleanroom environments.

R.D. Mathis Company’s Inert Gas Purifiers

R.D. Mathis Company supplies inert gas purification systems, power supply equipment, and evaporation sources for vacuum deposition applications. Supported by technical papers and extensive industry experience, R.D. Mathis Company supplies gas purifiers for processing inert gases to levels required for ultra-sensitive applications.

Visit our website to learn more.