Applications: Gold Evaporation Materials and Sputtering Targets in Thin Film Deposition

Gold (Au) is a precious metal with exceptional electrical, optical, and chemical properties, making it valued for a wide range of applications. In particular, gold evaporation materials enable thin film deposition processes, enabling engineered coatings with specific performance criteria to be applied to components.

1. Gold Evaporation Materials

1.1. Description

Evaporation materials are substances specifically designed for the process of physical vapor deposition (PVD). This technique involves the transformation of high purity solid material (for example, 99.999% pure material, or 5N pure for short) within a vacuum environment into a vapor phase. Atoms travel in a line-of-sight towards a substrate, subsequently condensing on the surface to produce a uniform thin film.

Image: Gold evaporation material in the form of pellets.

2. Gold Applications

2.1. Properties

Gold has high electrical conductivity, corrosion resistance, and optical reflectivity, making it useful for applications within electronic devices and optical systems. Aside from its functional properties, decorative coatings also use vacuum deposited gold for goods such as jewelry and watches.

2.2. Examples

- Electronics industry

- Gold evaporation materials find extensive use in microelectronics and semiconductor industry. They are employed to create thin films for components such as capacitors, resistors, and interconnects. Excellent conductivity and non-oxidizing properties of gold ensures reliability and efficiency of these devices.

- Optical coatings

- Components such as infrared mirrors and optical filters use gold films for its high reflectance. These gold coatings contribute to the development of high-performance optical systems.

- Medical devices

- Biocompatibility and resistance to tarnishing make gold suitable for applications in the medical field. Gold evaporation materials are used to coat medical devices, improving their durability and compatibility with the human body. This includes applications in prosthetics, implants, and also diagnostic tools.

- Decorative coatings

- Gold’s aesthetic appeal has made it a popular choice for decorative coatings. Thin films of PVD gold are vacuum deposited onto luxury goods to provide a durable finish compared to other coating methods.

3. Gold Evaporation Materials and Sputtering Targets

3.1. Methods

With a melting point of 1062°C, gold can be deposited using physical vapor deposition processes, depending on the system requirements and constraints. This includes:

- Thermal evaporation

- E-beam evaporation

- Sputter deposition

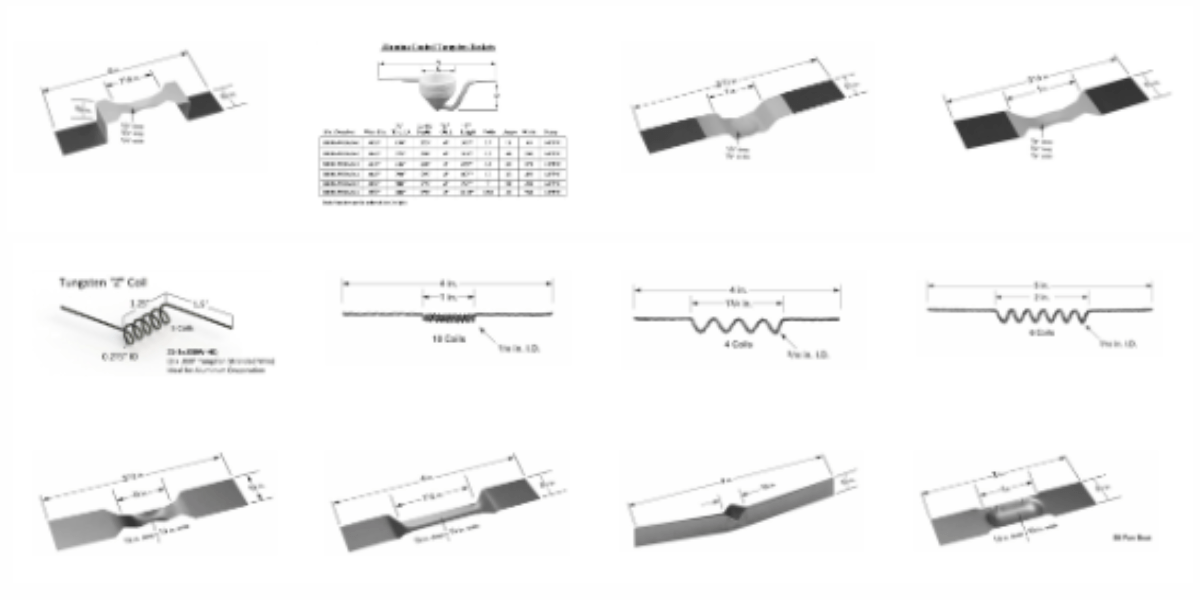

For smaller gold depositions, thermal evaporation is preferred. Alumina-coated evaporation sources maximize gold utilization by preventing material loss due to creep or corrosion of the source. The optimal evaporation source and method depend on parameters such as the required deposition quantity.

E-beam evaporation minimizes damage to heat-sensitive substrates due to how the electron beam produces localized heating on evaporation material. Sputter deposition uses ion bombardment rather than heating, which also prevents thermal damage to the substrate. It should be noted that meeting minimum fill levels for e-beam liners or sputter target costs may not be viable for smaller-scale coatings.

- Uniform deposition

- High purity gold evaporation materials, reaching purities such as 99.999%, enable the production of thin films with a high degree of uniformity to ensuring consistent performance.

- Controlled film thickness

- Researchers and manufacturers can also achieve precise monitoring and control over the thickness of the deposited gold film. This is done to control the film’s properties, meeting specific requirements of a specific application.

- Enhanced adhesion

- Gold evaporation contribute to improved adhesion of the thin film to the substrate, enhancing the overall durability and reliability of the coated material. Other processes, like electroplating, may wear out and scratch over time.

Sourcing Gold Evaporation Materials

R.D. Mathis Company supplies a range of evaporation materials produced to controlled specifications for thin film deposition applications. Whether you are in the electronics industry, optics, or any other field requiring superior thin film coatings, we provide gold evaporation materials known for their conductivity, corrosion resistance, and optical properties.