Applications of Gold Evaporation Materials and Sputtering Targets in Thin Film Deposition

Gold evaporation materials’ unique properties make them valuable for a wide range of applications, particularly in thin film deposition processes. Let’s explore the diverse applications of these materials and delve into the crucial role played by gold sputtering targets in advancing thin film deposition technologies:

Understanding Gold Evaporation Materials

These evaporation materials are substances specifically designed for the process of physical vapor deposition (PVD). This technique involves the transformation of a solid material into a vapor phase that subsequently condenses onto a substrate to form a thin film. Gold, with its excellent conductivity, corrosion resistance, and optical properties, is an ideal material for such applications.

Applications

- Electronics and Semiconductor Industry: Gold evaporation materials find extensive use in the electronics and semiconductor industry. They are employed to create thin films for components such as capacitors, resistors, and interconnects. The exceptional conductivity of gold ensures the reliability and efficiency of these electronic devices.

- Optical Coatings: The optical properties of gold make it a preferred choice for thin film coatings in optics. Gold evaporation materials are utilized to create films for mirrors, filters, and other optical components. These coatings enhance reflectivity and contribute to the development of high-performance optical systems.

- Medical Devices: Gold’s biocompatibility and resistance to tarnishing make it suitable for applications in the medical field. Gold evaporation materials are utilized to coat medical devices, improving their durability and ensuring compatibility with the human body. This includes applications in prosthetics, implants, and diagnostic tools.

- Decorative Coatings: Gold’s aesthetic appeal has made it a popular choice for decorative coatings. Gold evaporation materials are used to create thin films on various surfaces, contributing to the production of jewelry, luxury goods, and decorative elements in architecture.

Gold Sputtering Targets: A Key Player in Thin Film Deposition

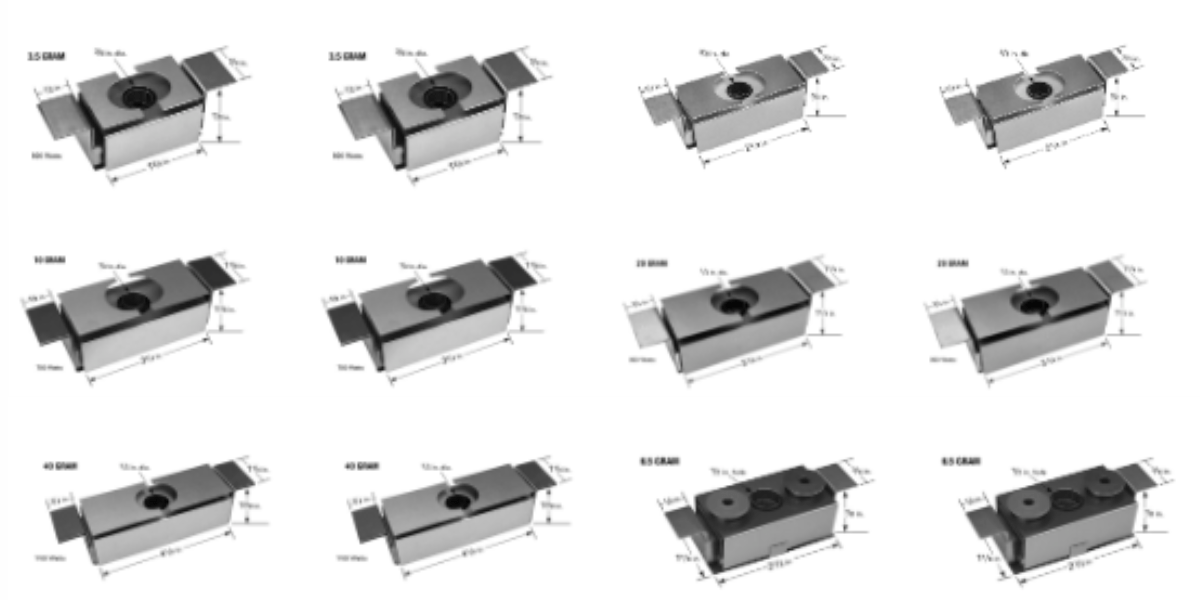

In addition to evaporation, another vital technique in thin film deposition is sputtering, and gold sputtering targets play a pivotal role in this process. Sputtering involves the removal of atoms from a target material, which then deposit onto a substrate. Gold sputtering targets are crafted with precision to ensure a controlled and uniform deposition of gold onto the substrate, offering the following advantages:

- Uniform Deposition: Gold sputtering targets enable the production of thin films with a high degree of uniformity, ensuring consistent performance across the coated surface.

- Controlled Film Thickness: Researchers and manufacturers can achieve precise control over the thickness of the deposited gold film, meeting the specific requirements of different applications.

- Enhanced Adhesion: Gold sputtering targets contribute to improved adhesion of the thin film to the substrate, enhancing the overall durability and reliability of the coated material.

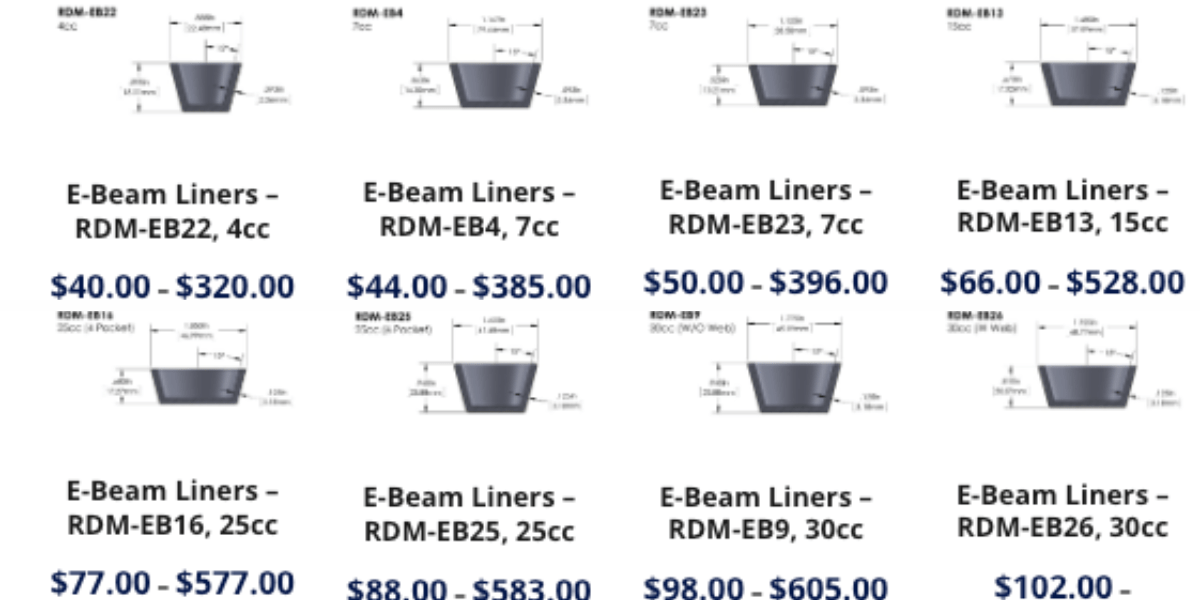

Shop R.D. Mathis’ Gold Evaporation Materials

As a trusted leader in the field of thin film deposition, R.D. Mathis Company offers a comprehensive selection of evaporation materials crafted to exacting standards. Whether you are in the electronics industry, optics, or any other field requiring superior thin film coatings, we provide gold evaporation materials known for their exceptional conductivity, corrosion resistance, and optical properties.