The Role of Silicon Monoxide in Vacuum Evaporation

In materials science and thin film deposition, silicon monoxide (SiO) plays a critical role, contributing significantly through its optical, electrical, and structural properties. This discussion examines the multifaceted functions of SiO coatings in thin film applications.

1. Silicon Monoxide Thin Films

1.1. Introduction

Silicon monoxide (SiO) is a black compound comprised of a single silicon and oxygen. It should not be mistaken with silicon dioxide, which is known to comprise silica or quartz.

Volatile at temperatures above 1100°C, SiO is valued for its use as a thin film material. When thermally evaporated, SiO forms small grain sized amorphous films, which adhere reasonably well to glass substrates.

1.2. Properties

Thin films of SiO demonstrate optical transparency and anti-reflective properties. As such, this material is used in various optical applications as an anti-reflection layer, which also serves to be scratch-resistant coating for lenses and mirrors as well.

Silicon monoxide shows low electrical conductivity which enables it as an insulating layer in electronics. It is used for capacitor dielectrics and also maintains thermal stability in electrical applications. With proper procedure, SiO deposition rates can be controlled for tunable, uniform layers in precision manufacturing.

2. Sources for Silicon Monoxide Deposition

2.1. Understanding the SiO Evaporation Process

In thermal evaporation processes, SiO does not melt before vaporizing, but instead sublimates. Despite this, SiO thin films are preferably deposited using resistive thermal evaporation. To address complications with SiO during thermal evaporation, it is essential to control evaporation rates and minimize particulate spitting.

Literature regarding SiO can be found in the following publications: Silicon Monoxide Evaporation with the Multi-Baffled Box Source and Silicon Monoxide – Properties and Evaporation Techniques.

2.2. Baffled Box Sources

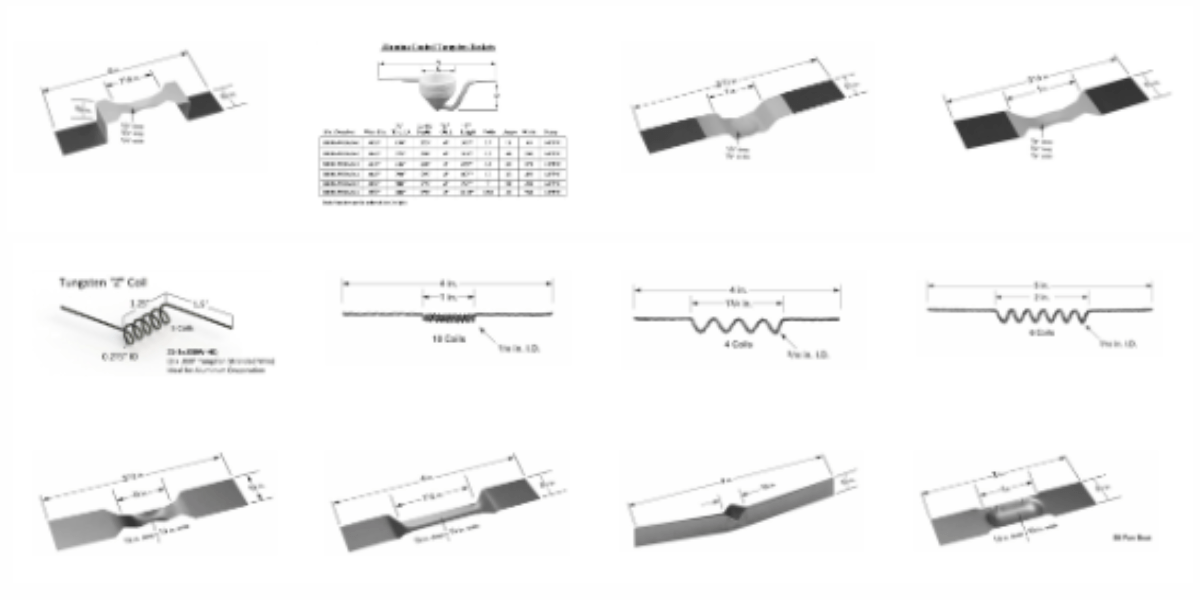

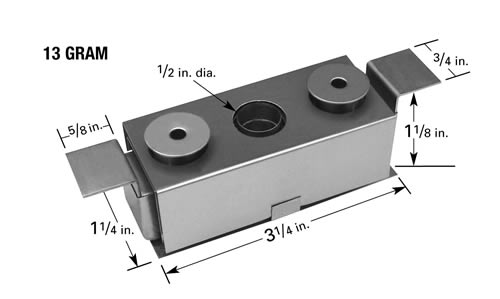

Specialized evaporation sources achieve this through redirecting SiO vapor through an indirect path. Baffled evaporation sources, such as the SO-24, are able to streamline this process. Baffled sources operate by making vapor follow an indirect path, eliminating particulates from depositing onto the substrate. The addition of heat shielding around the box ensures uniform temperatures during deposition. These sources are refillable for continued use, and can additionally come in larger capacities.

Sourcing Silicon Monoxide Evaporation Materials

Through collaboration between industry and research, SiO thin films provide the precision and efficiency needed for advanced applications. In addition to publications on SiO properties and evaporation source characteristics, further resources are offered in the R.D. Mathis technical library. These materials have supported both academic and industrial efforts in vacuum coating technologies.

The R.D. Mathis offers both silicon monoxide evaporation material and sources for SiO depositions. Contact us for more information and assistance.