The Role of Silicon Monoxide in Vacuum Evaporation

In the realm of materials science and thin film deposition, silicon monoxide (SiO) has emerged as a key player, contributing significantly to the efficiency and performance of vacuum evaporation processes. This post will shed light on the multifaceted role it plays in this critical aspect of material engineering:

Understanding SiO and the Evaporation Process

Silicon monoxide, or SiO, is a black compound comprised of a single silicon and oxygen. In thin film deposition processes, SiO is valued for its ability to form stable, uniform films. Heating SiO to its vaporization point in a vacuum forms thin films with particular optical and electrical properties.

Thin films of SiO exhibit many relevant properties. One of these properties includes its anti-reflective properties, making it used as an optical coating for lenses. Its low electrical conductivity allows it to be used as an insulating layer in electronics. Additionally, protective layer on mirrors see use of SiO due to its abrasion resistance.

Silicon Monoxide Process Advantages

- Stability and uniformity

- SiO exhibits remarkable stability during the coating process, ensuring consistent film quality. Its high melting point ensures its thermal stability, preventing it from breaking down under extreme temperature fluctuations.

- Compatibility with substrates

- SiO demonstrates good adhesion to substrates such as glass, expanding its applicability in different industries.

- Controlled deposition

- With proper procedure, SiO deposition rates can be controlled, creating uniform layers. This allows fine-tuning of the coating thickness, a crucial factor in manufacturing precision electronic and optical devices.

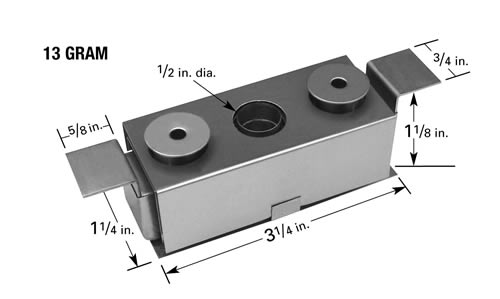

These advantages of SiO make it perform particularly well with thermal evaporation. To eliminate issues with SiO during thermal evaporation, the elimination of particulates and controllable evaporation rates are to be achieved. Baffled evaporation sources, such as the SO-24, streamline this process.

Sources for Silicon Monoxide Deposition

Baffled sources operate by making vapor follow an indirect path, eliminating particulates from depositing onto the substrate. The addition of heat shielding around the box ensures uniform temperatures during deposition. These sources are refillable for continued use, and can additionally come in larger capacities. See R.D. Mathis Company’s full selection of baffled box sources for more information.

Further details about SiO can be found in the following papers: Silicon Monoxide Evaporation with the Multi-Baffled Box Source and Silicon Monoxide – Properties and Evaporation Techniques.

R.D. Mathis Company’s Silicon Monoxide Evaporation Materials

With the continuous collaboration between industry and research, silicon monoxide thin films offers precision and efficiency for groundbreaking applications. Not only do we offer publications about silicon monoxide’s properties and evaporation source characteristics, but we have a technical library with more resources. We have supported academia and industry alike for vacuum coating technologies.

The R.D. Mathis offers both silicon monoxide evaporation material and sources for SiO depositions. Contact us for more information and assistance.