The Role of These 3 Tungsten Rods in Aerospace Applications

In the realm of aerospace engineering, where durability and resilience are paramount, tungsten rods have emerged as indispensable components. Let’s explore the high-performance applications, addressing not only their intrinsic qualities but also specific variations that play a crucial role in advancing aerospace technology:

Unrivaled Strength and Density

Tungsten’s exceptional density and strength position it as a material of choice for aerospace applications. Known for its high melting point and resistance to deformation, a tungsten rod contributes structural integrity to components, ensuring they endure the extreme conditions encountered during aerospace endeavors.

1. Chrome-Plated Tungsten Rods

When used in PVD applications, chrome-plated rods offer an added layer of protection against corrosion. Since tungsten has a higher melting point than chrome, this type of source makes depositing chrome streamlined for aerospace components.

Chrome plating enhances the substrate’s resistance to environmental factors, making them ideal for components exposed to varying atmospheric conditions during flight. This specialized chrome coating ensures longevity and reliability in aerospace systems, a critical consideration in these applications.

2. Tungsten TIG Rods

In aerospace fabrication, precision is key. Tungsten TIG rods, designed specifically for Tungsten Inert Gas (TIG) welding, play a vital role in joining aerospace components. The high melting point and non-consumable nature of tungsten TIG rods make them ideal for creating strong and precise welds in the fabrication of aircraft structures.

3. Tungsten Cathode Rods

Aerospace welding demands materials that can withstand the intense heat generated during the welding process. Tungsten cathode rods, with their high melting point and excellent thermal conductivity, contribute to the integrity of electron beam welding used in aerospace applications. These rods facilitate the creation of robust welds that meet the stringent safety and quality standards of the aerospace industry.

Challenges and Ongoing Developments

While these rods, including chrome-plated, TIG, and cathode rods, offer exceptional performance in aerospace applications, challenges such as weight considerations and cost-effectiveness persist. Ongoing research explores innovative alloys and manufacturing techniques to address these challenges, pushing the boundaries of aerospace technology.

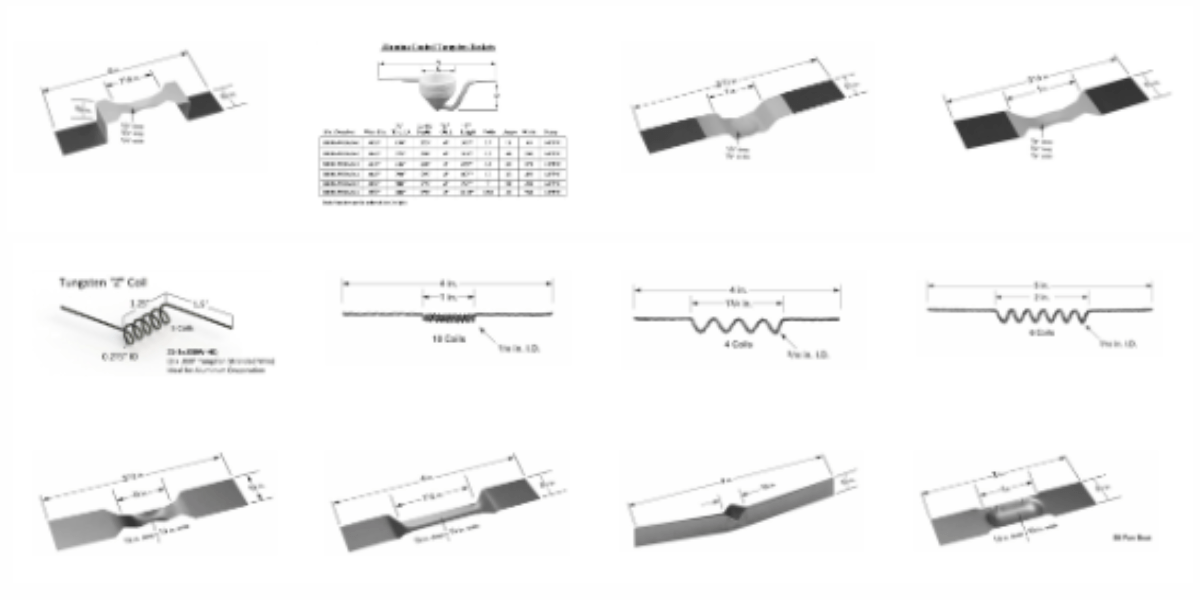

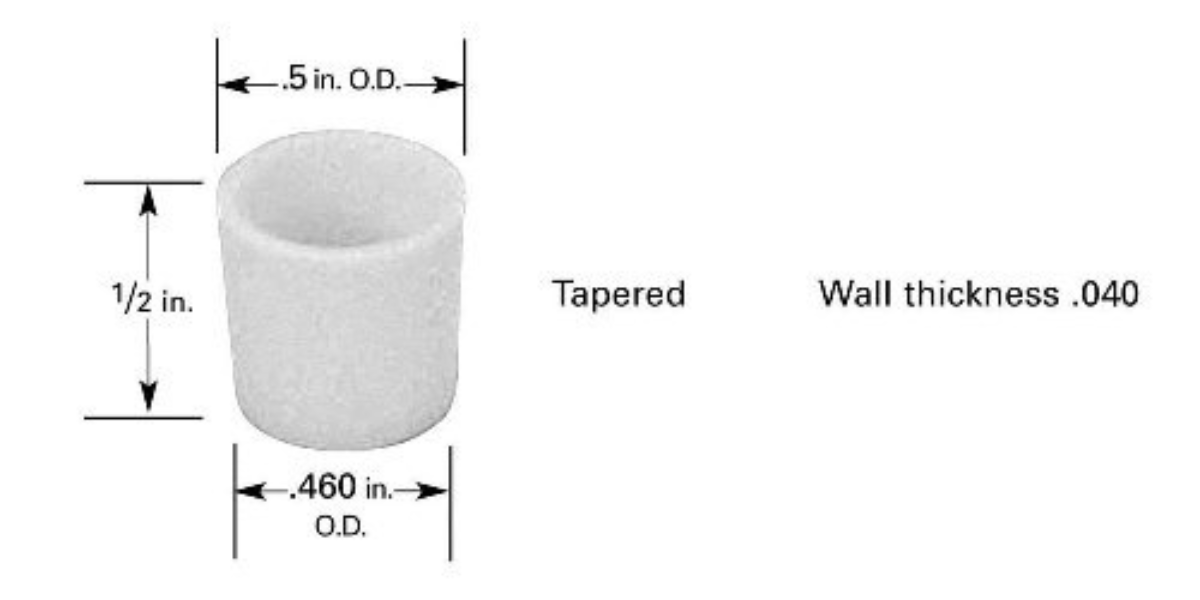

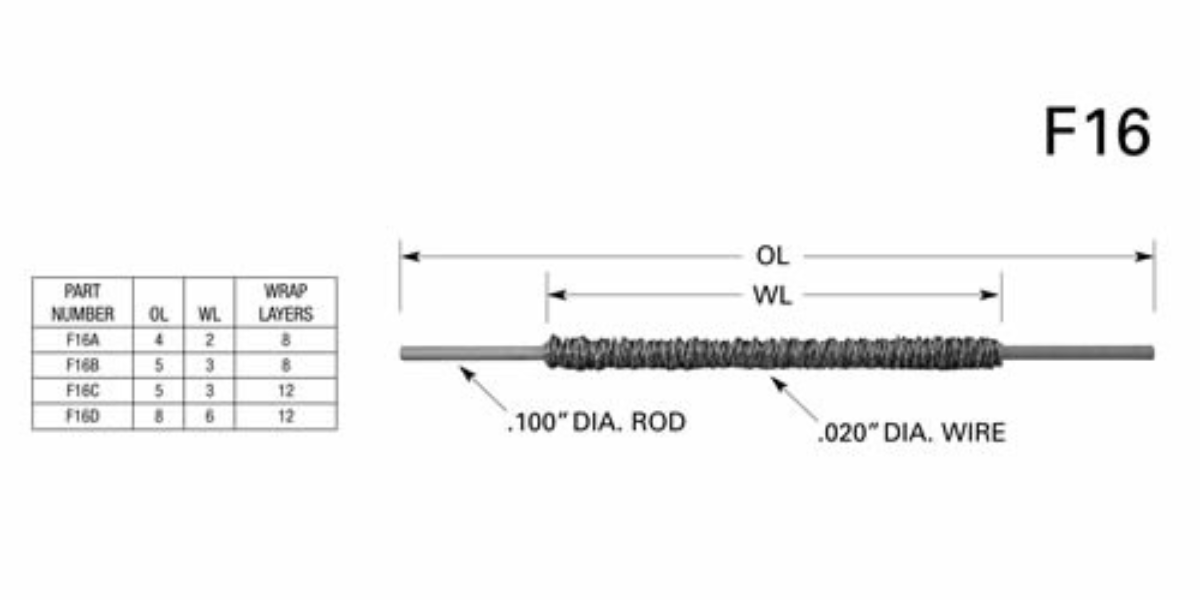

Shop R.D. Mathis Company’s High-Temperature Application Products

R.D. Mathis Company stands out as a leading provider of tungsten rods, contributing to the innovation and reliability crucial in space exploration and aviation. With a commitment to excellence and a focus on cutting-edge solutions, we exemplify the role of these products in shaping the future of aerospace technology.

Visit our website to shop our collection of tungsten materials.