Applications: Boats, Crucible Liners & Ceramic Crucible Boats

In high-temperature processes and material handling, component selection is critical for maintain process consistency. Common options include refractory boats, ceramic crucible boats, and crucible liners for containment of materials.

1. Refractory Boats

1.1. Description

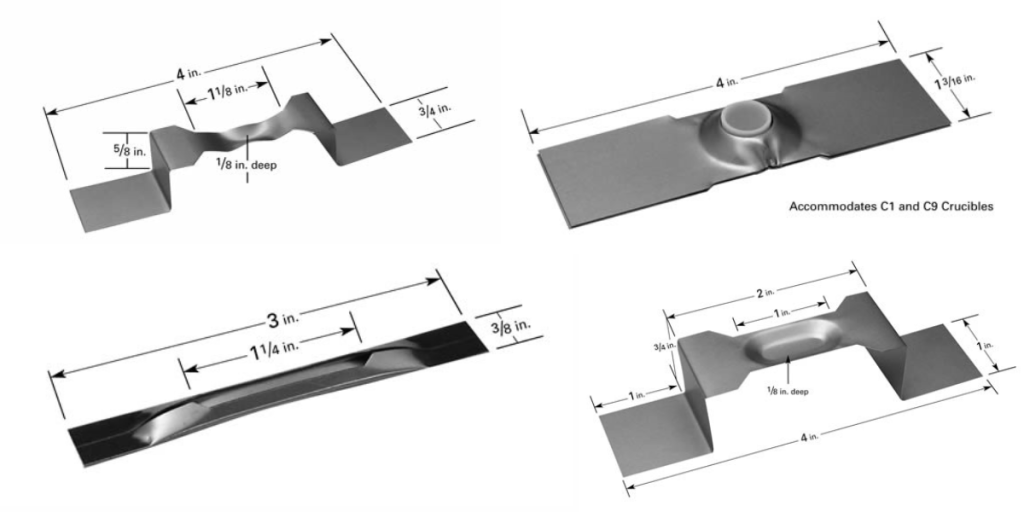

Refractory boats are metal containers fabricated from high melting point materials such as tungsten (W), molybdenum (Mo), or tantalum (Ta). These refractory metals are characterized by their extremely high melting points, which is necessary to facilitate vaporization under resistive thermal evaporation.

1.2. Design

In thermal evaporation, these boats are used as both containers and resistive heating elements under high vacuum conditions. As current is run through these boats, evaporation material placed inside turns into a vapor phase. The mechanical strength, material compatibility, low vapor pressure, and minimal outgassing ensures little contamination while undergoing several cycles.

In terms of choice, selections can be made based on factors such as evaporant compatibility, cost effectiveness, and flexibility. Molybdenum is often more budget friendly, tantalum can be shaped into various types of sources like crucible heaters and boxes, while tungsten is best to endure corrosion from materials like aluminum.

Further information about molybdenum, tungsten, and tantalum boats can be viewed here.

2. Ceramic Crucible Boats

2.1. Description

Ceramic crucible boats, made from high-purity ceramics like alumina, provide a vessel for containing materials during high-temperature processes such as sintering. Alumina provides thermal shock resistance and chemical inertness, providing stability for corrosive or high-temperature materials.

This type of container must be heated using an external heat source. For thermal evaporation, alumina coatings serve a similar purpose while retaining the ability to be resistively heated.

2.2. Thermal Evaporation Use Case

Alumina coated refractory boats handles issues of corrosive material containment during thermal evaporation deposition due the combination of resistive heating of tungsten or molybdenum and a layer of alumina. For the evaporation of materials such as gold, nickel, and copper, this inert layer helps keep material contained while avoiding corrosion due to alloying.

3. Crucible Liners

3.1. Description

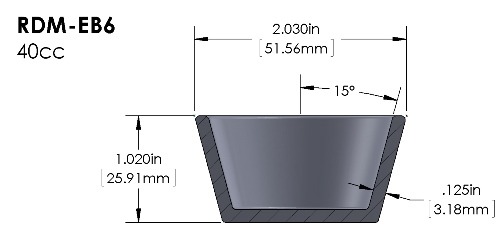

Crucibles serve as purely containment and rely on another source to provide thermal energy. In e-bean deposition, crucible liners are used alongside a electron beam for vaporizing material. These liners can be fabricated from a wide variety of different materials, i.e. ranging from copper or vitreous carbon crucible liners to aluminum oxide and boron nitride.

One notable material includes tungsten, known for its high melting point, dense structure, and low vapor pressure also make them suitable for this high vacuum process. Depending on individual compatibility with the deposited material, metals, intermetallics, and ceramics are all used for different e-beam liner applications.

Image: Diagram of a crucible liner

Boat and Crucible Sourcing

Refractory boats, ceramic crucible boats, and crucible liners provide solutions for material containment and handling in high-temperature deposition processes. The R.D. Mathis Company offers a comprehensive range of these components to support diverse thin-film and vacuum applications.

With decades of experience in high-temperature process equipment, the R.D. Mathis Company manufactures refractory boats, alumina-coated sources, and crucible liners with precision and expertise. These products deliver reliable performance, durability, and stability under demanding operating conditions.

Visit our website to shop our entire collection, including boats and crucible liners.