0

You have 0 items in your cart

- Home

- Products

- Evaporation Sources

- Alumina Coated Sources

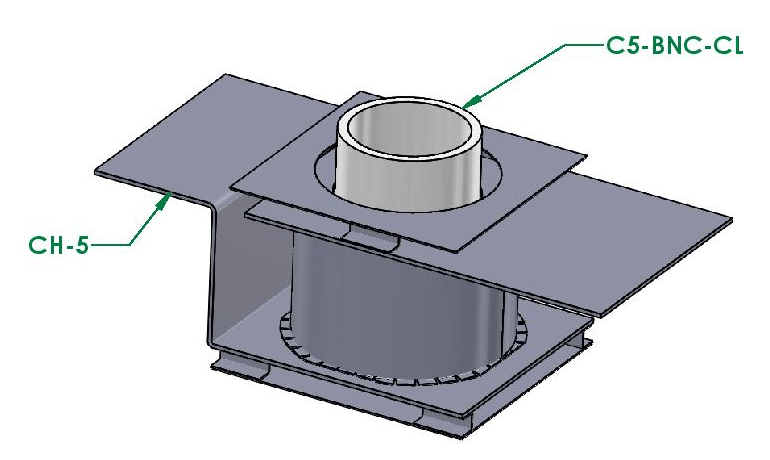

- Baffled Box Sources for SiO and ZnS

- Baskets and Heaters

- Chrome Plated Tungsten Rods and Tungsten Screens

- Crucibles and E-Beam Liners

- Folded Baffled Box Sources

- Folded Boats

- Micro Electronic Sources

- Point Source Filaments

- Shielded Crucible Heaters

- Special Boats Tantalum

- Tungsten Filament Evaporation

- Tungsten, Tantalum and Moly Evaporation Boat Sources

- Evaporation Materials

- Equipment & Accessories

- Evaporation Sources

- Technical Library

- FAQ

- Media

- About Us

- News/Blog