0

You have 0 items in your cart

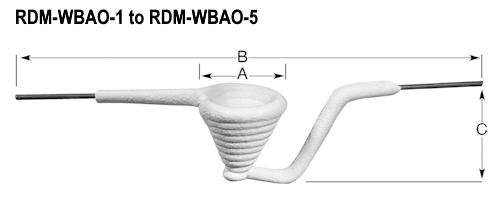

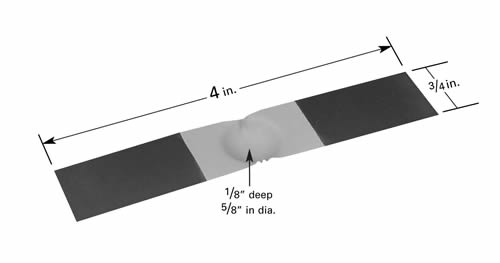

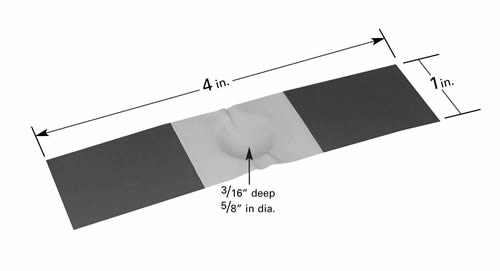

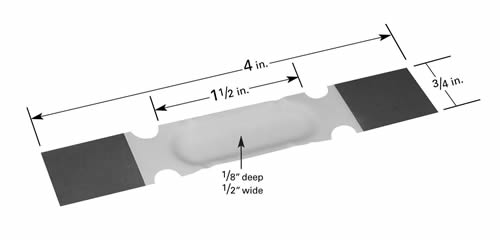

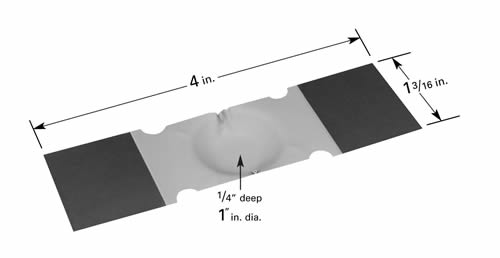

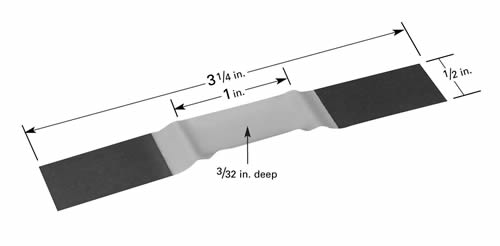

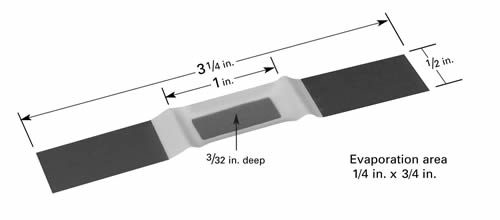

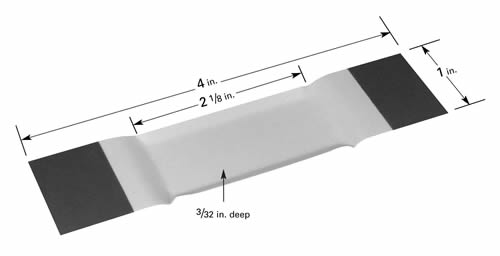

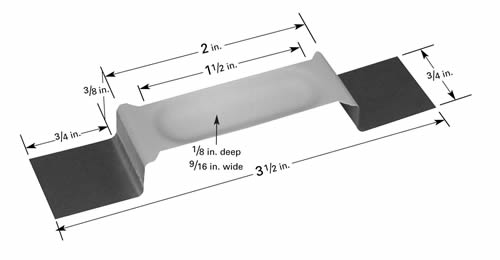

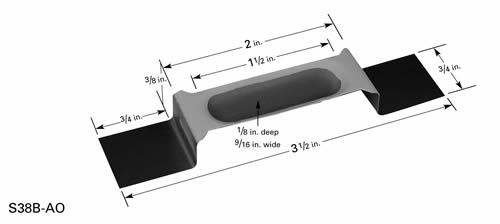

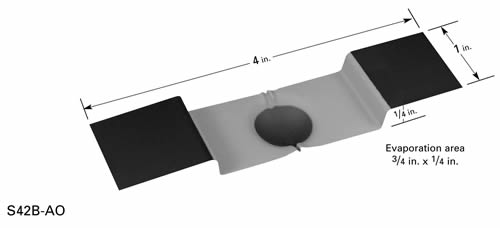

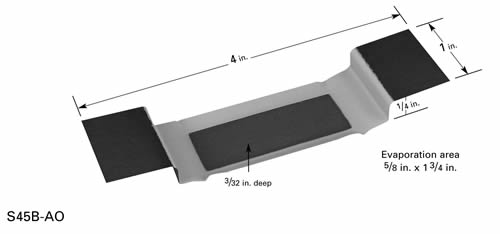

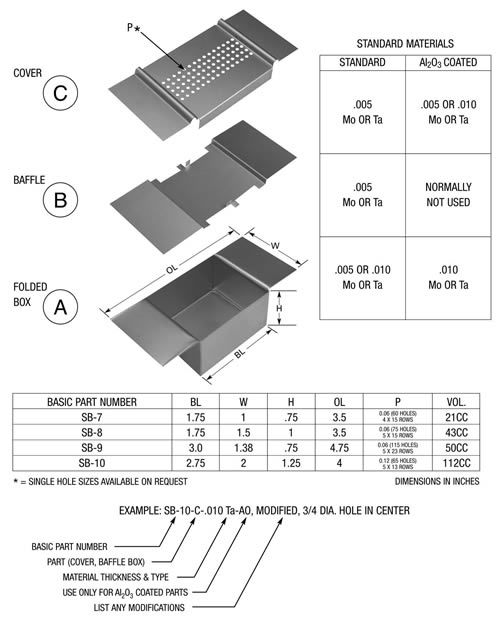

The aluminum oxide (AO) coated evaporation sources was developed to replace alumina crucible boats in thermal evaporation. Semiconductor-grade aluminum oxide is applied to the boat/basket by plasma spray technique.

Alumina displays inertness with most molten metals. AO coated sources will require 30-50% more power to affect evaporation due to differences in thermal conduction. When evaporation is affected, power should be slightly reduced to avoid overheating.

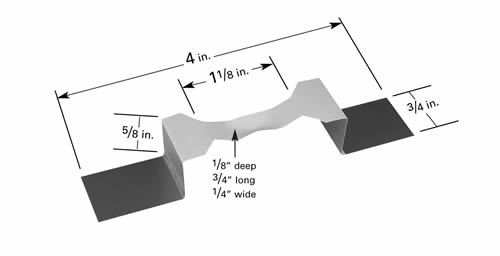

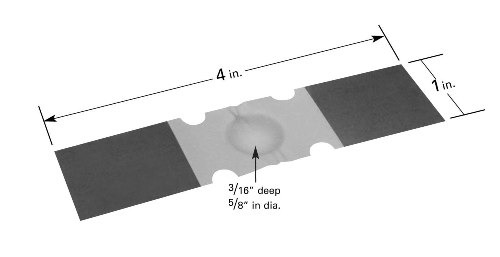

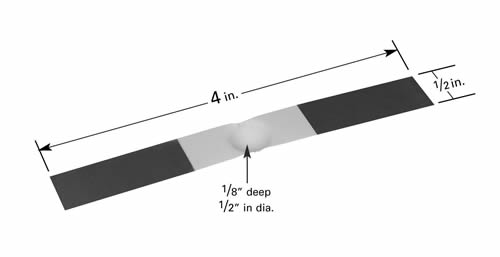

Alumina coatings done in a barrier-style exposes a metal area at the bottom of a boat while maintaining a perimeter of alumina. This allows evaporant to have direct thermal contact with the boat, while also inhibiting material creeping or wetting toward the boat or heat sink.