Choosing the Right Source for Your Thermal Evaporation Process

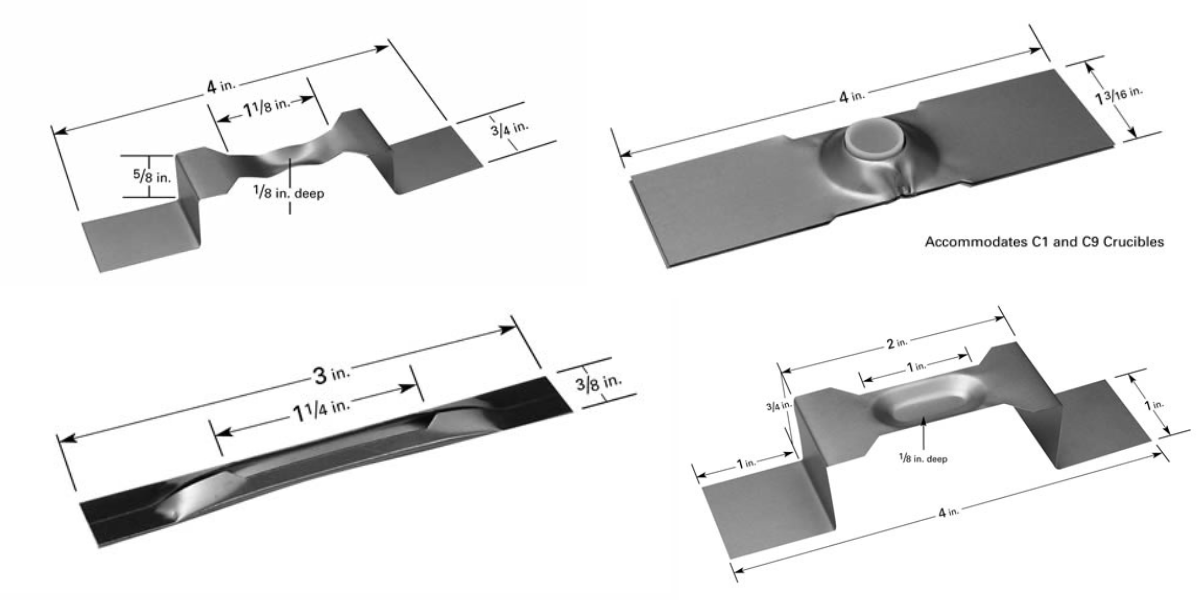

In thermal evaporation, the evaporation source provides both containment and heating for high purity evaporation materials. These sources range in terms of refractory material, form factor (varying designs for boats and filaments), and thicknesses.

Choosing the right source for your thermal evaporation process affects process consistency and source lifetime. Source selection depends on many factors, such as the evaporation material and the system used for the thin film process.

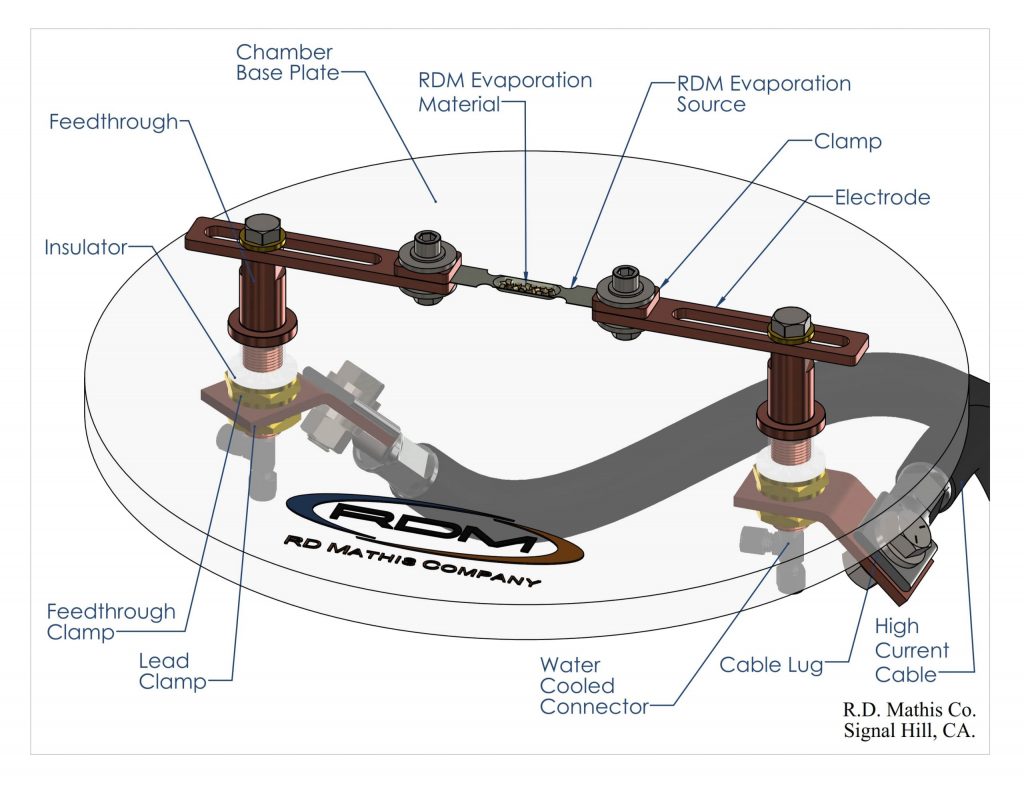

The diagram above illustrates the typical layout of a thermal evaporation system within a vacuum chamber.

1. Factors to Consider When Choosing a Source

Selecting optimal sources is dependent on several process factors. This includes material compatibility, system limitations on space and power, and film thicknesses. This leads the way to several options when it comes to sources, such as tungsten, tantalum vs. molybdenum or using alumina coatings to minimize migration and corrosion.

Although a wide selection of evaporation sources are available, specialized processes may require custom fabrications, which the R.D. Mathis Company can provide to meet specific needs.

1.1. Evaporant

Depending on the material being evaporated, the evaporation source material may or may not be compatible with the evaporant. Certain materials can corrode the evaporation source, necessitating thicker material to mitigate cracks and source failure. For more details, see our Thin Film Evaporation Source Reference Guide in our technical library for specific recommendations.

1.2. Temperature

Temperature requirements have an effect on the selection process. Higher temperature processes may benefit from heat shielding to protect components inside the vacuum system. See heat shielded crucible heaters or baffled box sources.

1.3. Dimensions

What is minimum & maximum length that will fit in to your mounting scheme? Some systems may be limited to smaller sources such as filament sources. Micro-electronic sources are an option for space limitations of two inches between electrodes.

1.4. Power Supply

How much power do you have to heat the source (amperage)? Smaller sources and thinner material require less power. Reference power requirements can be found in our technical library under the Power Requirement Table.

1.5. Other Factors

Standard sources are available for specialized applications where large capacity is needed or vapor stream direction needs to be redirected for deposition onto substrates.

- Capacity: What capacity will you need to achieve your desired thickness?

- Direction: Are you evaporating upwards, downwards or sideways?

- Source to Substrate: What is your required throw distance?

2. Thermal Evaporation of Gold

Gold thin film deposition by thermal evaporation can be achieved through a variety of methods, including boats, baskets, crucibles, or filaments. However, proper handling of gold is necessary to ensure a repeatable deposition process.

2.1. Alumina Coatings

In liquid state under vacuum conditions, gold is moderately corrosive and will wear down sources such as boats. Under these conditions, gold will also creep to cooler areas of the boat, leading to process losses during the deposition.

Alumina-coated evaporation boats provide an ideal solution to solve these problems. Compared to uncoated boats, alumina-coated boats are more heavy duty and require approximately 30% more power input. Typical material is .010″ thick tungsten, which offers enough to withstand corrosion for several deposition cycles. This alumina coating is utilized in many ways to enhance thermal evaporation applications.

2.2. Types of Alumina Applications

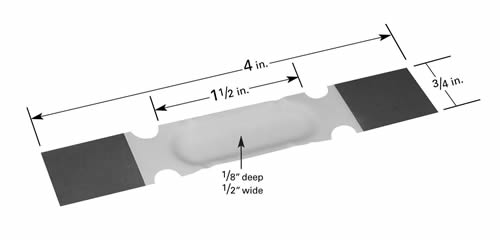

Advantages of fully coated sources, such as the S21-AO-W, comes from the alumina coated dimple area, preventing the gold from wetting which eliminates migration and corrosion.

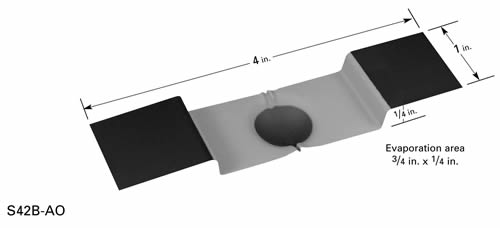

On the other hand, alumina coating can be applied as a barrier style, such as on the S42B-AO-W. This provides similar wetting preventation to full alumina coatings, but also allows thermal contact with the tungsten for heating efficiency.

To support this process, R.D. Mathis Company offers high purity gold pellets, wire and sputtering targets in a variety of sizes and quantities.

3. Thermal Evaporation of Aluminum

Aluminum is a widely used material for thermal evaporation, and spitting (which leads to pinhole defects) is generally not a problem for this material.

3.1. Corrosion-Resistant Sources

Nevertheless, there are a few common problems that occur during aluminum evaporation. In contrast with gold, aluminum metal reacts with aluminum oxide coatings, which interferes with film composition. Moltent aluminum is highly corrosive which leads to premature failure of evaporation sources during the deposition. In addition, aluminum exhibits migration or creeping as it wets to the source surface and escapes the evaporation area.

Tungsten demonstrates the most resilience to aluminum corrosion. For small aluminum depositions, filaments, baskets, or rod sources are suitable. Larger amounts necessitate the need for boats, boxes, or crucible heaters for deposition. Specialized cool lip crucibles are offered specifically to control wetting of aluminum, minimizing migration out of the crucible for higher volume processes.

For more information about cool lip crucibles, see R.D. Mathis Company’s ½” diameters and 1” diameters, designed to be compatible with crucible heater sources.

4. Thermal Evaporation of Nickel

Similar to gold and aluminum, nickel exhibits corrosive and migratory behavior during thermal evaporation, complicating the deposition process. Not only is nickel corrosive with most source materials, but it also demonstrates aggressive wetting and often escapes the evaporation area.

4.1. Nickel Deposition Strategies

Several strategies can be used to manage these difficulties, achieving repeatable successful evaporation processes. For small nickel depositions, tungsten baskets fabricated from stranded tungsten wire are applicable. Stranded baskets are cost-effective, simple to operate and replace, and require low power requirements, making them well-suited.

For processes requiring extended source lifetime, R. D. Mathis Company’s series of alumina-coated tungsten baskets are a suitable option. These sources operate at comparable power levels to stranded baskets while offering increased durability to control nickel behavior during evaporation

Additional information about alumina coated tungsten baskets and related evaporation sources can be found by contacting the R.D. Mathis Company.

5. Conclusion

These considerations offer baseline factors for determining the appropriate thermal evaporation source for your application. Drawing on decades of experience in the thin film industry, R.D. Mathis Company offers additional technical assistance for both basic processes or application-specific custom requirements.

The R.D. Mathis Evaporation Source Selection Guide is available for reference. This guide outlines difference source geometries depending on process conditions and what optimal conditions they operate under. See more under the expanded technical library section from R.D. Mathis Company.