What is a Tungsten Thermal Boat?

The tungsten thermal boat, or W boat (named after its chemical symbol), is container made from tungsten sheet resembling a boat. These commonly see use for extremely high-temperature processes, such as those in the materials science, chemical or research industries.

Thermal boats are made out of refractory metals; however, tungsten sees use for its exceptional corrosion-resistant properties and notably higher melting point. This makes tungsten thermal boats ideal for extreme temperature conditions for research and manufacturing applications.

See also: molybdenum thermal boat and tantalum thermal boat.

The Design and Purpose

A thermal boat’s design typically consists of a trough-like structure with raised edges that resemble a simple boat. Tungsten, known as a refractory metal, has the highest melting point on the periodic table. This, alongside its chemical resistance and good thermal conductivity, thus makes tungsten ideal for manufacturing thermal boats.

The main purpose of a tungsten thermal boat is to hold and transport materials during high-temperature processes, such as thermal evaporation, sublimation and furnace applications. These boats are loaded with solid materials, such as metals, semiconductors or compounds, which need to be heated to high temperatures to facilitate vaporization or reaction.

Common Applications

- Thin Film Deposition

- In physical vapor deposition (PVD) processes, tungsten boats are used to hold the evaporant material (e.g., metal, alloy or other material) that is heated to produce a vapor. This vapor then condenses on a substrate, forming a thin film.

- Thicker tungsten thermal boats are used for evaporants that may corrode through other boat materials or thinner boats.

- High-Temperature Reactions

- Tungsten boats or heating elements are well known for their use in high-temperature reactions, allowing pinpoint control of temperature during the containment of reactants.

- Tungsten boats or heating elements are well known for their use in high-temperature reactions, allowing pinpoint control of temperature during the containment of reactants.

- Crystal Growth

- For crystal growth processes that require melting and crystallizing of materials, tungsten can act as a container or crucible, facilitating growth of single crystals.

- For crystal growth processes that require melting and crystallizing of materials, tungsten can act as a container or crucible, facilitating growth of single crystals.

- Materials Testing

- These boats are used in laboratories, used jointly with various material characterization and analysis techniques, making them relevant for thermal analysis, high-temperature microscopy and thermogravimetric analysis.

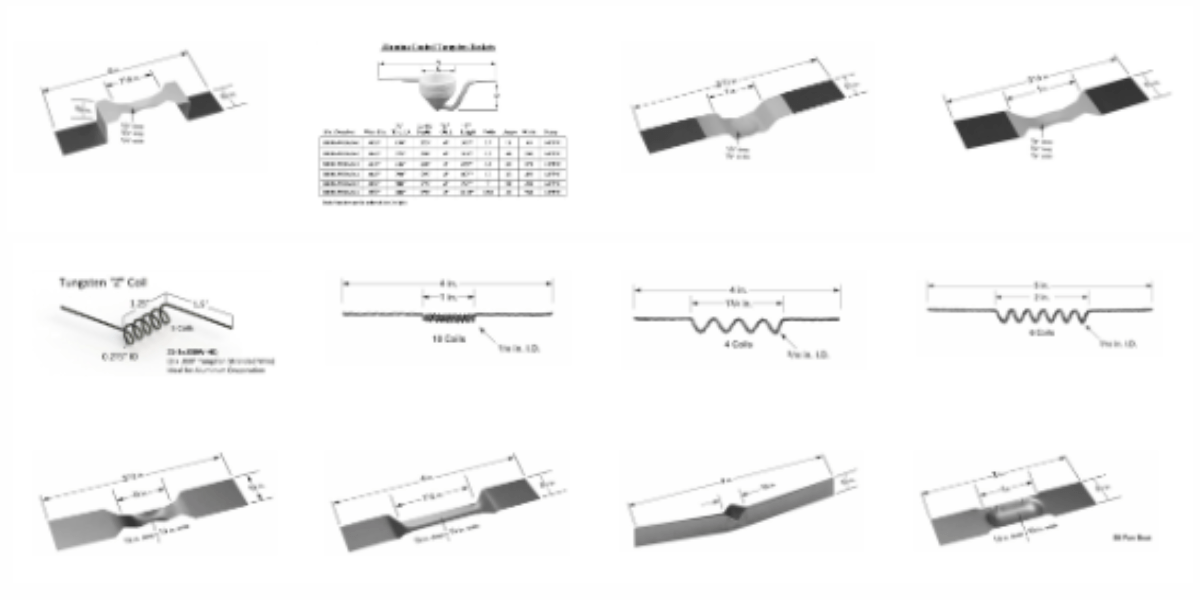

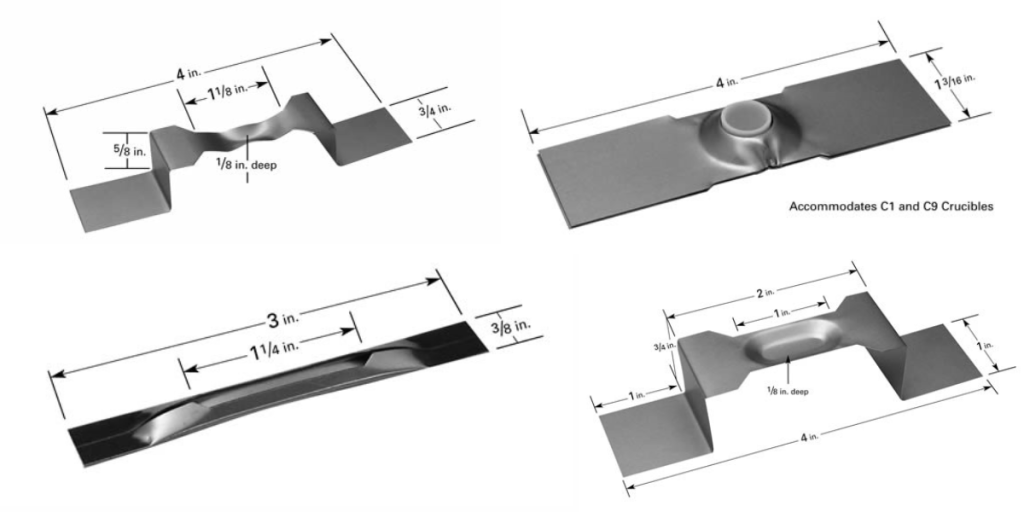

These tungsten thermal boats come in a variety of thicknesses, sizes and geometries for various evaporation applications and set-ups. For high temperature materials, tungsten is recommended for these applications due to its ability to resist deformation or reacting at these conditions. These boats are highly durable and long-lasting as tried and proven tools within industry and research.

Shop Tungsten Thermal Boats

Our tungsten thermal boats at R.D. Mathis Company are widely known for their outstanding reliability in high-temperature applications. Quality manufacturing from high purity tungsten guarantees superior thermal conductivity and chemical resistance for high temperature industrial and research applications.

All of our evaporation boats are available in a variety of materials and thicknesses — visit our website to shop now.