What is Thermal Evaporation?

Thermal evaporation is a specialized type of method used in manufacturing and research to deposit thin films of material onto a substrate. This process involves heating a material in a vacuum chamber until it vaporizes and then condenses onto a substrate.

1. Process Overview

1.1. Vacuum Set-Up

The thermal evaporation process begins with a vacuum chamber, typically made of stainless steel, providing an environment to minimize contamination. Inside this chamber, the high purity materials to be deposited (also known as the evaporant) is placed inside:

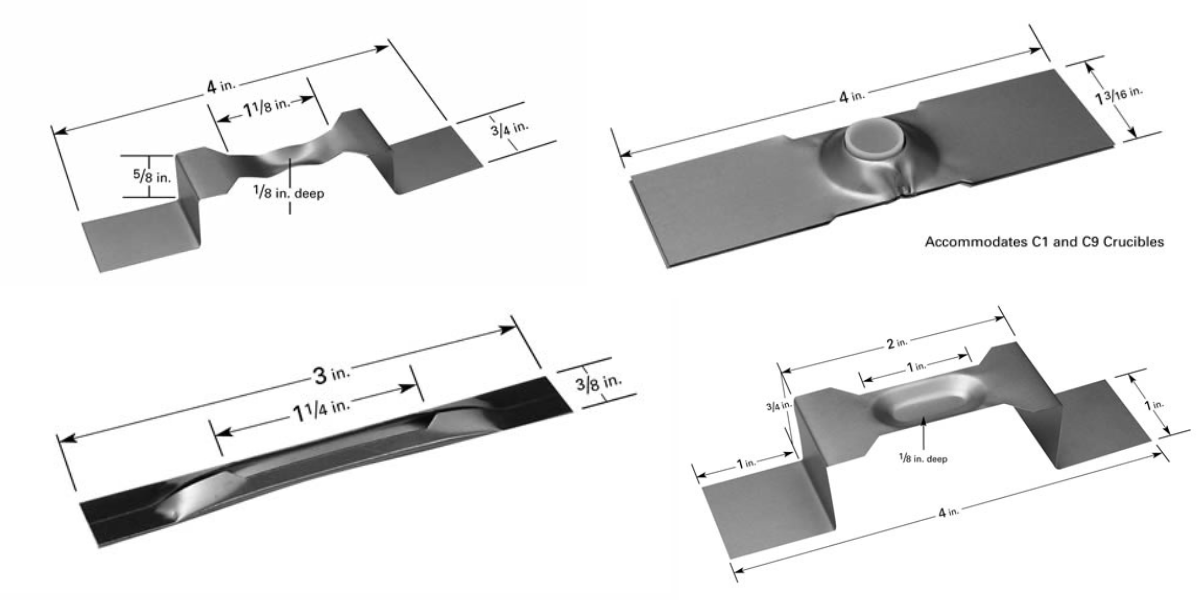

- a refractory boat, fabricated from either tungsten, molybdenum, or tantalum;

- crucible, paired with a crucible heater;

- or tungsten filament/basket.

1.2. Source Heating

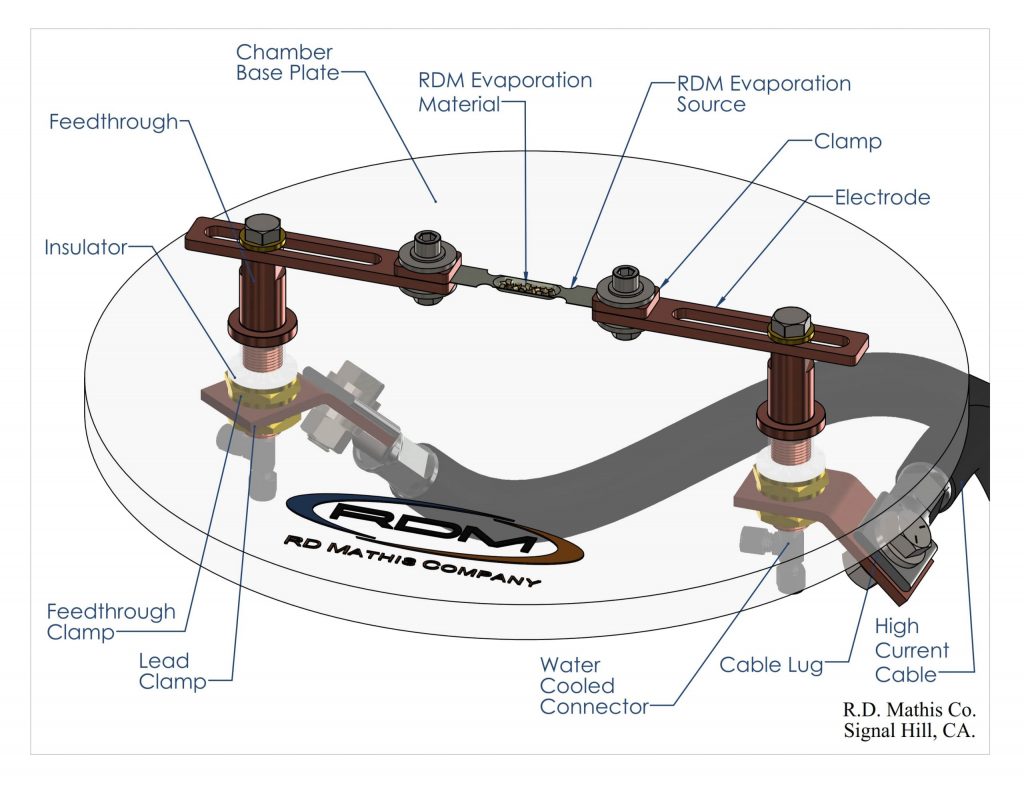

These boats, filaments, and baskets are known as evaporation sources and operate through resistive heating. This type of heating specifically requires a high current power supply, connected to the vacuum chamber via feedthroughs and electrodes.

The system evacuates the chamber to a high vacuum to remove residual gases that could interfere with deposition. Depending on the deposited material, the required vacuum level typically ranges from 10^-5 to 10^-7 Torr.

1.3. Film Formation

Deposition systems use substrates, typically placed on a holder that moves and rotates to ensure uniform deposition across its surface. Substrates may also be heated to promote adhesion between the deposited material and the substrate.

As the evaporant heats up, it vaporizes into a cloud of atoms travelling in a straight line towards the substrate. Afterwards, this vapor cloud condenses on the surface of the substrate, forming a high-purity thin film. Film thickness is controlled by monitoring factors such as:

- temperature of the evaporant (thermocouple monitoring)

- rate of deposition (quartz crystal monitors, QCMs tracking real-time thickness)

- and also the distance between evaporant and substrate (throw distance)

By controlling these factors, such as ensuring a controlled rate and sufficient source-to-substrate distance, uniform films can be deposited repeatedly and reliably with thermal evaporators.

2. Advantages of Thermal Evaporation

2.1. Benefits

Thermal evaporation is a versatile method that can deposit a wide range of materials, including metals, semiconductors, and organic compounds.

Compared to other PVD methods, this vacuum deposition process is widely used due to its simplicity and cost-effectiveness. Methods such as e-beam evaporation (minimum fill level of liners) or sputtering (target utilization costs) have higher upfront costs due to the source material costs.

2.2. Applications

The ability to deposit ultra-thin films allows precise control over electrical conductivity, reflective properties, and wear resistance. Researchers and manufacturers commonly employ this method to fabricate electronic and optical devices, including solar cell contact layers, OLED displays with organic materials, and microelectromechanical systems (MEMS).

See examples of some common materials for thin film applications here.

Resources for Thermal Evaporation

The R. D. Mathis Company is the leader in thermal evaporation sources and has a wide selection of products in the catalog as well as custom fabrication to meet your specific needs.

Visit our website for more information.