E-Beam Evaporation Sources in Modern Thin Film Deposition

Electron beam evaporation (also known as electron beam deposition) stands out as a versatile and widely used process for thin film deposition. This method falls under a class of vacuum-based techniques known as physical vapor deposition (PVD), characterized by the physical transformation of source material into a vapor phase, condensing onto a substrate to form a thin film.

1. Electron Beam Deposition

1.1. Overview

E-beam deposition utilizes a high-energy electron beam to provide localized heating to vaporize evaporation material. As a result, vapor travels inside the vacuum chamber environment, ensuring minimal contamination and allowing precise control over deposition parameters.

E-beam evaporation sources are specifically designed to generate and focus a high-energy electron beam onto a target material, causing it to heat up and sublimate. The sublimated material then condenses onto the substrate, forming a thin film with the desired properties. This source is responsible for delivering the necessary energy to vaporize the target material and controlling the direction and intensity of the electron beam.

1.2. Advantages

E-beam evaporation sources offer several advantages over other PVD techniques. The electron beam enables efficient heating of the source material, resulting in extremely pure films of extremely high temperature materials. This makes this technique ideal for applications that require high-quality thin films of materials such as molybdenum or tungsten.

These e-beam systems can handle a diverse range of materials, including metals, oxides, semiconductors and organic compounds. This versatility allows for the deposition of multi-component films, alloys and graded structures, expanding the possibilities for tailoring material properties.

They also offer excellent control over deposition parameters, such as film thickness, deposition rate and uniformity. The ability to modulate the electron beam intensity and scan the substrate ensures precise and reproducible results.

2. E-Beam Evaporation Sources

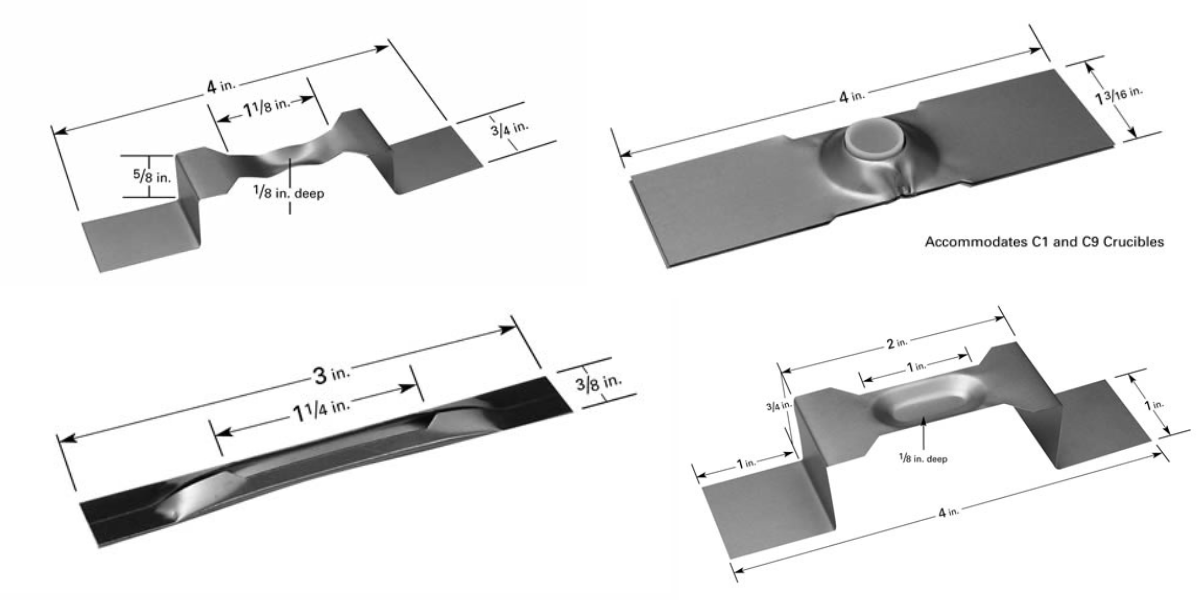

An e-beam system is equipped with liners and other parts to handle material and producing the electron beam. For more information about e-beam evaporation, see more about the materials, sources, and crucibles used or briefly explore advanced dual e-beam evaporation technology and their capabilities.

R.D. Mathis Company is a widely-used and reputable manufacturer of vacuum deposition products and accessories, which includes e-beam crucible liners, evaporation materials, and e-beam filaments. Visit our website to learn more or view our selection.