Exploring Alumina Boat Crucibles: Properties, Applications, and Benefits

Alumina boat crucibles have emerged as indispensable tools for high-temperature materials processing. With their unique properties, wide-ranging applications and a host of benefits, these crucibles are essential for industries that require precision and reliability in extreme heat conditions.

Properties

Alumina crucible boats are crafted from high-purity aluminum oxide (Al2O3), commonly known as alumina. This material exhibits remarkable thermal stability, enabling the crucibles to withstand temperatures well over 1700°C without compromising their structural integrity.

Alumina’s excellent thermal conductivity ensures uniform heat distribution, crucial for processes such as melting, sintering and annealing. Furthermore, its chemical inertness prevents reactions with various molten metals and corrosive materials, maintaining the purity of processed substances. This combination of properties makes these crucibles ideal for demanding applications that involve reactive materials and high temperatures.

Applications

The versatility of alumina boat crucibles is evident in their widespread applications across various industries. In laboratories, these crucibles find utility in material research, thermal analysis and quality control due to their consistent heat distribution and inert nature.

Industries such as semiconductor manufacturing rely on these crucibles for the growth of single crystals and the deposition of thin films. In metal casting and foundries, they serve as reliable containers for molten metals during casting processes. Alumina crucible boats also play a critical role in ceramics production, supporting the sintering of ceramics to achieve desirable shapes and properties. In essence, wherever high-temperature processing is involved, alumina boat crucibles step up to the challenge.

Benefits

The benefits of alumina crucibles are multifaceted. Their exceptional thermal stability ensures consistent performance under extreme heat, leading to improved process control and repeatability. The chemical inertness of alumina safeguards against contamination, crucial in industries that demand high material purity. Their durability and resistance to thermal shock contribute to their longevity and reliability.

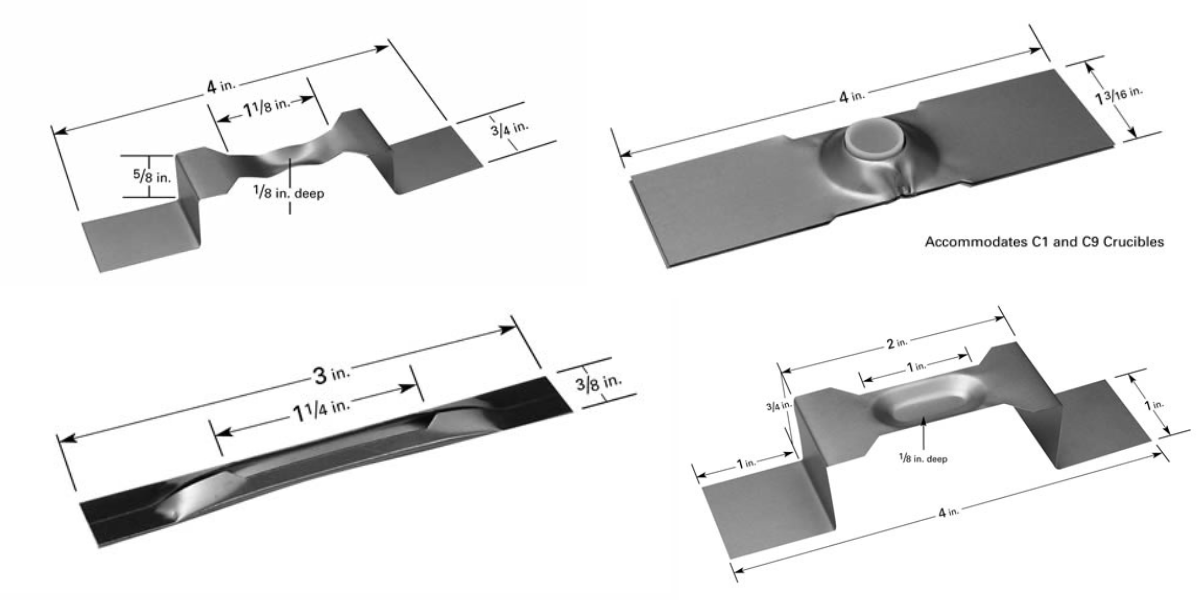

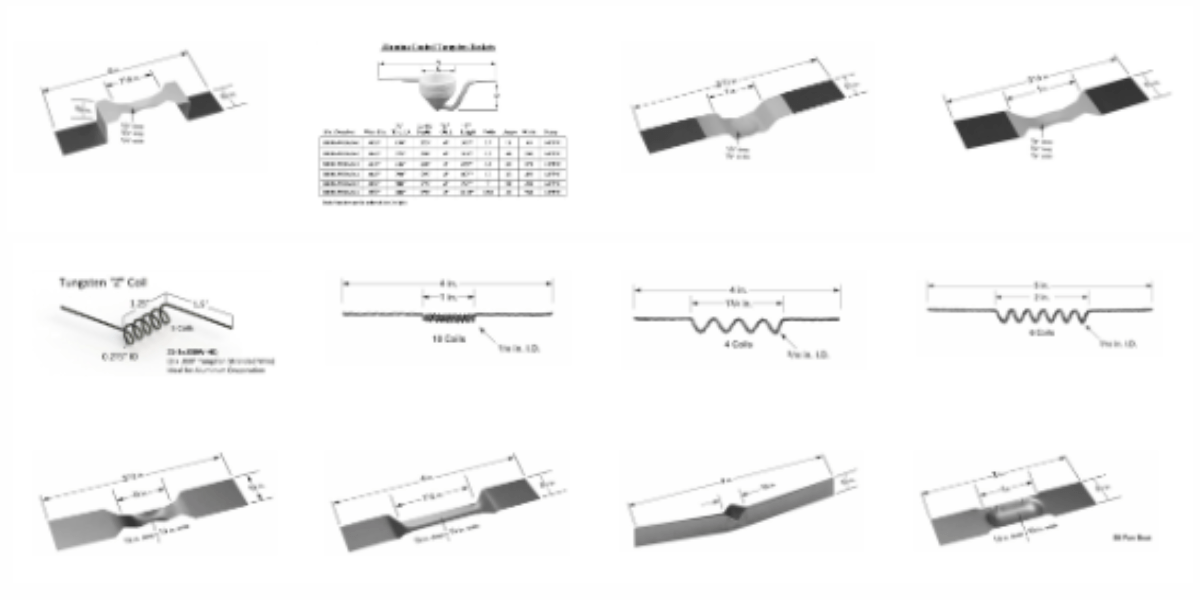

Moreover, alumina crucibles are available in various shapes and sizes, offering customization options to suit specialized applications. These are not only efficient, but also environmentally friendly, as alumina is a readily available and recyclable material.

Shop Alumina Boat Crucibles

R.D. Mathis Company’s alumina boat crucibles stand as a cornerstone of progress, enabling industries to achieve precision and excellence in the most demanding high-temperature processes.