E-Beam Evaporation: Materials, Sources, and Crucibles

Electron beam evaporation (or E‑beam evaporation) is a high‑precision physical vapor deposition technique used to deposit thin films for use in fields such as electronics, optics, and materials science.

E-beam deposition can be broken down into key components, including the materials to be deposited, the sources used, and the crucibles that contain the material during evaporation.

1. E-Beam Evaporation Materials

1.1. Introduction

E-beam deposition relies on the vaporization of specific materials to deposit a thin film onto a substrate. The choice of materials is critical and depends on the desired properties of the thin film. Common materials include metals, dielectrics, and organics.

1.2. Examples

Thin film metal deposition for metals such as aluminum, gold, and titanium are often used for electrical conductivity and optical applications. Dielectrics like silicon dioxide and silicon nitride are chosen for their insulating properties. Organics generally may include polymers or organic semiconductors. This broad range of materials allows e-beam deposition to be compatible with many applications requiring controlled films.

Evaporation Material Fill Levels

Keep in mind the amount of material used for E-beam deposited coatings. Underfilling can cause damage to the crucible liner that holds your material. For smaller quantities, you may want to consider vacuum thermal evaporation instead.

Image: Various different evaporation materials, including pellets and sputtering targets

2. E-Beam Evaporation Sources

2.2. Working Principles

E-beam sources are responsible for generating the electron beam that heats the evaporation material. In an e-beam system, a tungsten filament emits electrons when heated. These electrons are then focused into a beam using magnetic fields and directed towards a target region. As a result of the beam striking the material, vaporization occurs and enables deposition onto a substrate.

Due to the targeted heating enabled by e-beam sources, these systems enable high levels of control over the precision and uniformity of thin films for use in applications such as semiconductor manufacturing. Additionally, the temperatures provided by these sources allow for high melting point materials, such as refractory metals, to be deposited.

3. E-Beam Evaporation Crucible

3.1. Purpose

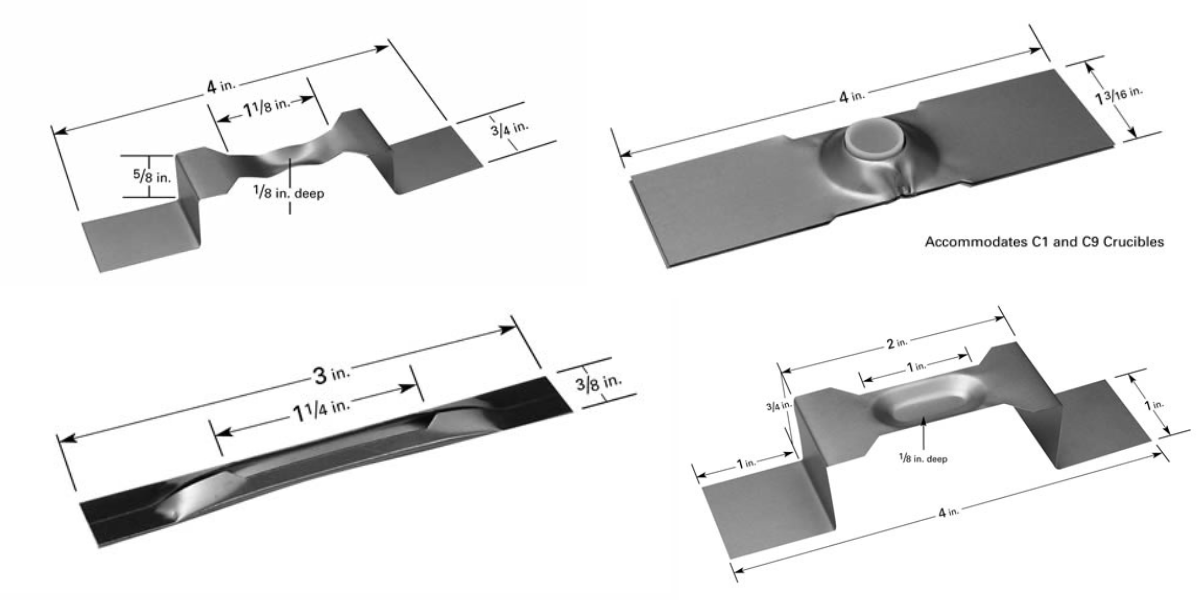

An e-beam evaporation crucible is a container that holds the evaporation material during the deposition process. Crucibles, made to fit with specific e-beam system sizes, are fabricated from materials chosen for their stability at the high temperature required for vaporization. Some common materials include molybdenum and tungsten crucible liners for their extremely high melting points.

3.2. Criteria

The selection of e-beam evaporation crucibles depends on the specific application as well as scaling the amount of material to be evaporated. It is essential to choose a crucible liner that is compatible with the evaporation material, fits within the e-beam pocket, and provides enough volume for the quantity needed for coating.

Sourcing E-Beam Crucible Liners

By selecting the right parameters and ensuring material compatibility, e-beam deposition can be versatile for depositing thin films in a variety of different industries. Aligning crucible design and material choice with the deposition material enhances both the efficiency and reliability of the process.

R.D. Mathis Company’s availability of e-beam crucibles can be used to support standard e-beam systems, or custom needs as well. See also more about Dual E-Beam evaporation technology.