Applications: Tungsten Wire in Modern Industries

Tungsten, a high performance metal with exceptional properties, has established itself into many industries due to its unique combination of mechanical and electrical properties. One of the key forms in which this material is used is in the shape of tungsten wire.

1. Tungsten Wire in Materials Science

1.1. General Characteristics

For broad applications, tungsten exhibits properties such as good electrical conductivity, strength, and heat resistance. However, tungsten differentiates itself from other metals by maintaining these properties in extreme temperature ranges, with the material having a melting point of approximately 3410°C.

1.2. Vacuum Characteristics

Combined with a low vapor pressure, tungsten is ideal for contamination-free applications within vacuum environments. For high temperature applications, tungsten wire can also form non-sagging heating elements that resist deformation and thermal expansion.

2. Applications in Thermal Evaporation

2.1. Introduction

Thermal evaporation is a vacuum deposition process that uses resistive heating to vaporize evaporation materials, which then condense to form a thin film on the surface of a substrate. Tungsten wire is one of the materials which these resistive heating elements (evaporation sources) are fabricated from, which includes:

These wire sources are used for thin films of many electrical components such as aluminum or nickel for reflective layers on solar panels, diffusion barriers on PCBs, and much more.

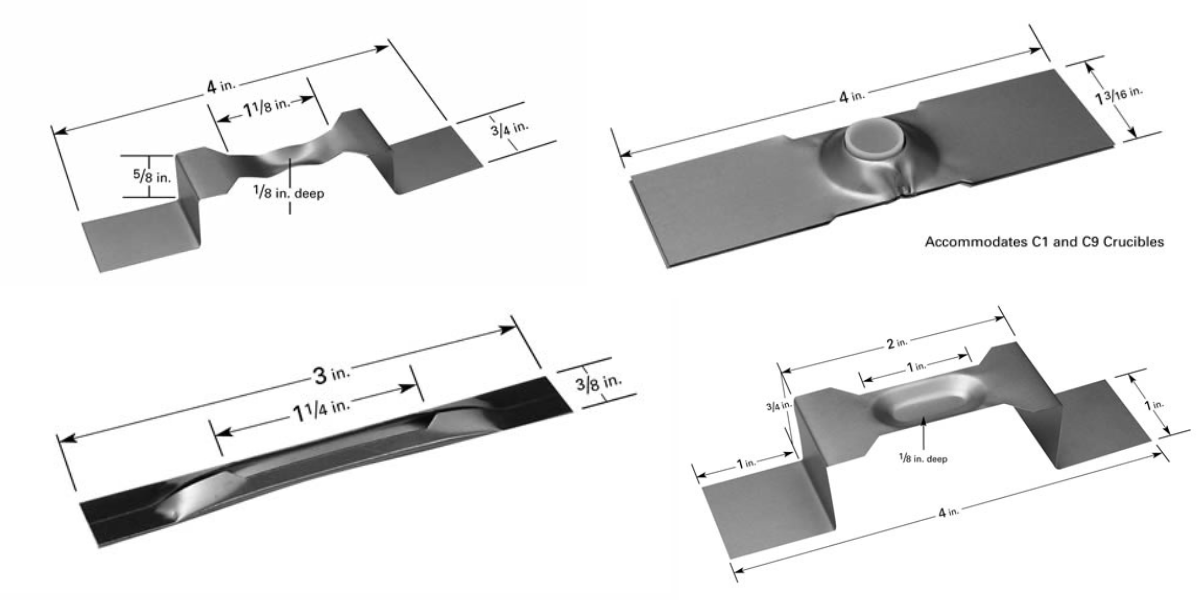

2.2. Tungsten Filaments, Baskets, vs. Basket Heaters

In tungsten filaments and baskets, the wire, which is typically multi-stranded to increase surface area, holds material for thin film deposition through wetting of molten material. Depending on the type of coating and direction of vapor needed, both tungsten filaments and baskets see use in thermal evaporation.

Although similar to tungsten baskets, basket heaters are designed to be fitted with crucibles and thus do not use wetting nor direct heat conduction to heat materials to their vaporization temperature. This style of resistive heating also allows deposition of evaporation materials with poor wetting or chemical compatibility.

3. Electron Emission Technology

3.1. Electron Beam

Tungsten filaments are used as a cathode to generate electron beams, which are used in applications, i.e. cathode-ray tubes. Deposition systems use this in a e-beam evaporator, using the generated flow of electrons and directing them to produce a beam of high energy. Localized heating occurs, which vaporizes atoms and subsequently condenses material into thin film coatings.

4. Miscellaneous Vacuum Applications

4.1. Substrate Heating

Resistive wire heating elements are used for thermal evaporation purposes, but can also be used as substrate heaters. While other processes, such as sputter deposition, might not directly use tungsten wire, they can employ substrate heaters to improve film properties.

4.2. Thermocouples

There are many different wire types used for thermocouple applications. Depending on the temperature range, these wires are accordingly made from a variety of different metals and alloys.

Tungsten rhenium wires, which is an alloy comprised mostly of tungsten, see use in some vacuum applications as an extremely high-temperature thermocouple wire.

4.3. Emerging Technologies

As technology advances, so does the use of tungsten wire. Emerging technologies, such as 3D printing and nanotechnology, are exploring tungsten’s unique properties for various applications.

Sourcing High Purity Tungsten Wire

Tungsten wire exhibits a combination of high mechanical strength, thermal stability, and electrical conductivity, making it a critical material across numerous industries. Its ability to perform reliably under extreme conditions has established tungsten wire as a preferred material for a wide range of applications.

R.D. Mathis Company has consistently been a source for tungsten wire products that meet demanding standards for research and industry use. Our team manufactures tungsten filaments in many shapes and forms, including high vacuum applications to furnace heating elements for laboratories and research. For more information, please contact us for a quote.

Shop for our tungsten filament sources today.