Vacuum Deposition Solutions: Impact of Inert Gas Purification

1. Background

Vacuum deposition is a crucial process in various industries, from semiconductor manufacturing to optical coatings and advanced materials research. The objective of vacuum deposition is to create thin films with precise mechanical, optical, and electrical properties, but this requires stringent control and monitoring. An inert gas purifier provides valuable control over the vacuum environment to improve process reliability.

1.1. Impact

Commercially available inert gases often contain residual gases or vapors. As is, these inert gases may be sufficient for general industrial applications such as food processing or production welding. For vacuum processes, these gases (which can be around 99.8% pure) may need purities reaching levels such as 99.9991% pure.

2. Process Control in Vacuum

2.1. Reduced Contamination

Contamination, whether from moisture, oxygen, or other impurities, can severely impact the quality and performance of processes that require inert gases in vacuum. Such examples include handling sensitive materials, including specialty metals in vacuum furnaces or ion beam etching on substrates.

In the context of thin film deposition, trace contaminants in inert gases used in physical vapor deposition systems can form unwanted oxides or other compounds in the source material. Without using an inert gas purifier, defect incorporation and decreased film uniformity can occur.

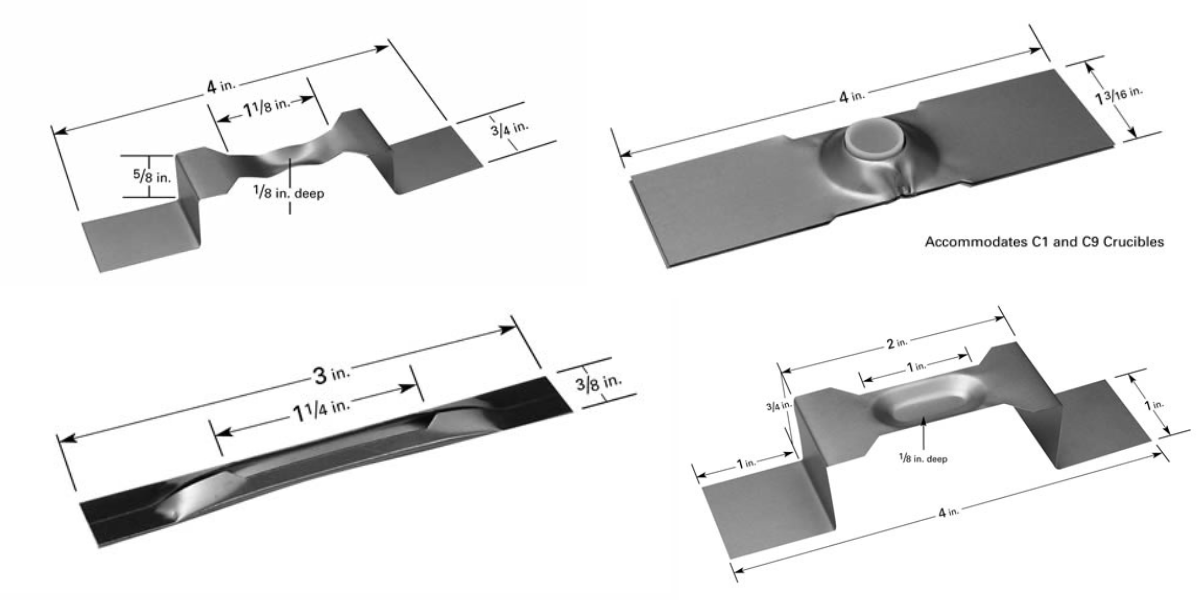

R.D. Mathis Company Inert Gas Purifier

2.2. Controlled Reactions

Some applications use inert gases as a non-reactive environment (replacing atmospheric gases) to control chemical reactions for reactive compounds. Laboratories may require chemical reactions to occur in a glove box for the synthesis of materials that oxidize easily.

Sputter deposition processes use similar principles, using argon as a sputtering gas while flow of reactive gas is managed to facilitate controlled reaction. This enables the reaction of elemental source material to form compound thin films, e.g. silicon forming silicon dioxide or titanium forming titanium nitride films.

3. Effects on Process

3.1. Film Purity and Uniformity

Uniform stochiometric thin films are essential in many applications where materials need to meet certain electrical or optical properties. Film non-uniformity and defect sites can lead to performance inconsistencies or device failure, especially in semiconductor applications.

3.2. Substrate Sensitivity

Alongside thin film coating materials, certain substrates used in vacuum deposition are highly sensitive to environmental conditions. Exposure to water vapor, oxygen, or other contaminants can degrade the substrate’s properties. Silicon wafers can form silicon dioxides on its surface, which need to be removed or otherwise prevented with an inert gas purifier.

Sourcing Inert Gas Purifier Models

In conclusion, inert gas purifiers mitigate risks associated with unwanted residual particles when used in vacuum chambers or as a purging gas. These contaminant-free, dry, and inert conditions enable processes such as thin film deposition, synthesis of easily oxidizing materials, and vacuum metallurgy.

RD Mathis Company delivers specialized solutions in vacuum deposition equipment, enabling precise control and high-quality outcomes in thin film coating processes. For literature about the purification of inert gases, see published papers within the technical library.