Choosing the Right Crucible for Your Laboratory Applications

Processing and storing materials at elevated temperatures requires proper equipment selection and procedure. Crucibles are widely used for handling sensitive compounds across several applications. Options such as tungsten, boron nitride, or alumina crucibles are commonly available for different process requirements, making the selection process critical for success.

1. About Crucibles

1.1. What Is a Crucible?

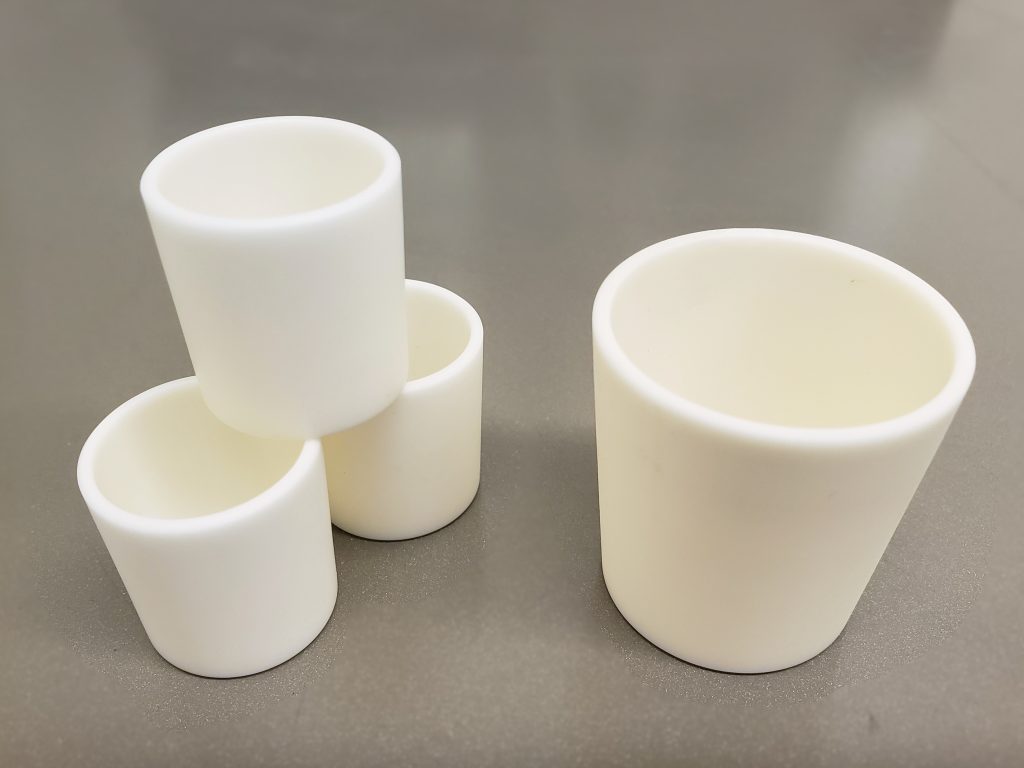

A crucible is a container used to contain material for processing during operations such as heating or chemical reaction. Their geometry, which is typically in the shape of a cup, allows for easy loading and unloading. Metallurgy, materials research, and laboratories use a wide range of crucibles of different types.

The crucible can come in many (customizable) sizes, shapes, and materials including high temperature metals, graphite, quartz, or ceramic materials. Aluminum oxide, a white ceramic, is a notable crucible material for its thermal stability, chemical resistance, and mechanical strength.

2. Factors to Consider

2.1. Temperature Resistance

One of the most critical factors to consider when selecting a crucible is its temperature resistance. Different laboratory processes require varying degrees of heat, and thus choosing a crucible that can withstand the intended temperature range is essential for process safety.

Tungsten crucibles and other refractory metal crucibles can endure conditions with extreme temperature changes and thermal shock.

2.2. Chemical Compatibility

Chemical interactions between crucible and transported substances can damage the container. Crucible materials vary significantly in their chemical inertness depending on the conditions. For instance, alumina crucibles are generally resistant to most acids, bases, and solvents, but compatibility may vary depending on specific reagents used in your laboratory.

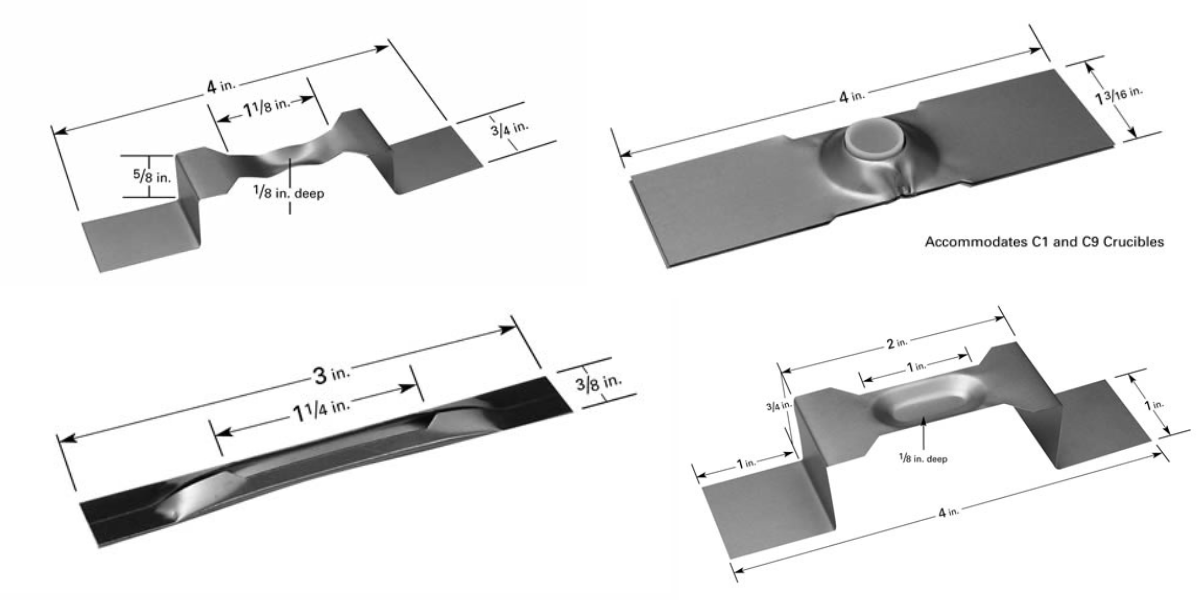

2.3. Size and Capacity

Crucibles come in a range of sizes and capacities to accommodate different volumes. Consider the volume of material to be handled and space available within your laboratory set-up. For example, undersizing a crucible and doing multiple pours can affect end results in applications like metallurgy.

2.4. Purity and Finish

The surface finish of the crucible can impact its performance in certain applications. A smooth surface significantly reduces friction, minimizes the risk of sample contamination, and facilitates easy cleaning. Glossy carbon and graphite, while both carbon based, also have different surface finishes.

Crucible purity can also prevent contamination in sensitive environments. Therefore, high-purity alumina crucibles have become preferred for analytical work and processes where sample contamination must be minimized.

3. Thermal Evaporation Applications

3.1. Conditions Under Thermal Evaporation

Thermal evaporation systems use crucibles to contain source material, then vaporize and condense it to form thin films. These crucibles operate under vacuum at extremely high temperatures and work in conjunction with crucible heaters or basket heaters to achieve the required temperatures.

RD Mathis Company offers a wide selection of alumina crucibles and other crucible materials for use in scientific research and laboratory applications. These products are designed to accommodate diverse experimental and processing requirements. For more information about crucibles or crucible heaters, see the R.D. Mathis website for information.