Analysis: Traditional Thermal Evaporation vs Baffled Box Sources

Selecting the proper evaporation source is a key decision in thermal evaporation systems due to how source design directly affects film uniformity, quality, and consistency of a process. Thermal evaporation offers flexibility through a range of source designs, including traditional evaporation sources or baffled box sources, enabling deposition of a variety of materials.

This analysis evaluates the design of each evaporation source and the application contexts where complex designs demonstrate advantages. Results of this are summarized in the Evaporation Source Selection Table by the end of this review.

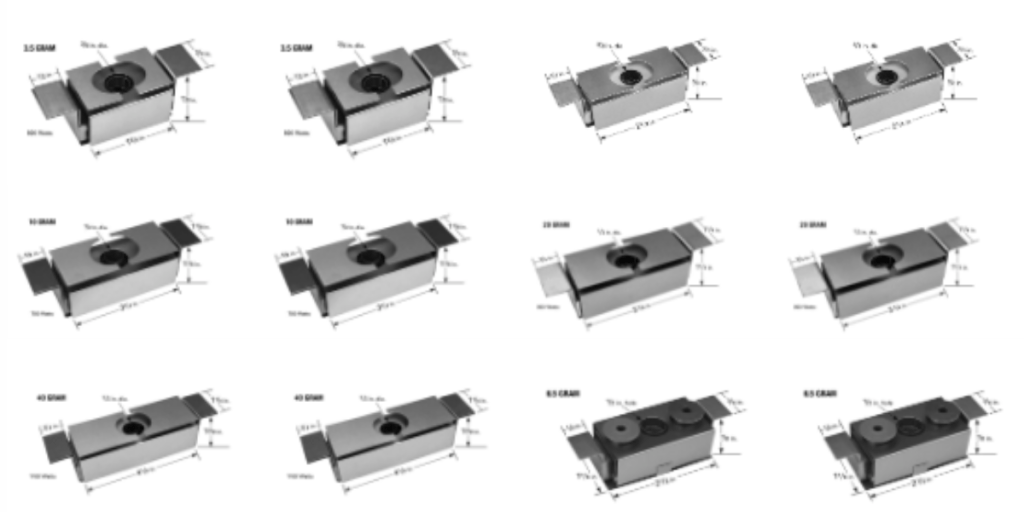

1. Baffled Box Source

1.1. Design

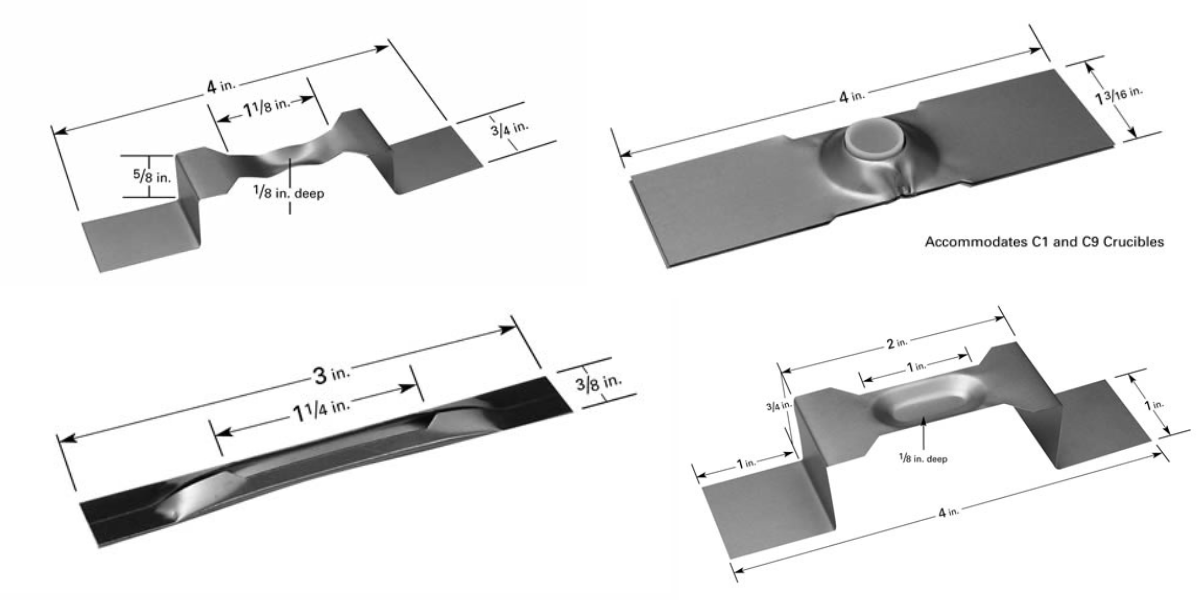

Baffled box sources are a specialized type of resistive thermal evaporation source that integrate internal baffles into an enclosed box. These baffles create a controlled path for the vapor stream that filters solid particulates captured in the vapor. In comparison, simple boat sources have direct line-of-sight that can introduce pinhole defects if working with material that spits.

Alongside baffling, these box sources incorporate heat shielding to achieve better thermal efficiency and reduce radiant heat that can damage vacuum chamber components. Exhaust ports or chimneys are used in this type of design to control the direction of the evaporated material. These can be used to redirect the vapor stream in horizontal or downward directions.

1.2. Advantages

- Uniform deposition: Exhaust ports and baffles redirect the vapor flux, resulting in more uniform coatings.

- Blocking spitting: The baffles help to reduce particulates in the vapor stream. This reduces pinhole defects for applications that require smooth films.

- Material efficiency: These sources have higher material utilization rates, as baffles help minimize waste.

- Versatility: Suitable for a wide range of materials, including silicon monoxide and zinc sulfide.

1.3. Challenges

- Complexity: Their design and operation are more complex than traditional sources, requiring more sophisticated handling and maintenance.

- Cost: Generally, baffled box sources are more expensive upfront due to their specialized design.

See the Evaporation Source Selection Table section below for summarized findings.

2. Traditional Thermal Evaporation Sources

2.1. Basics

Traditional thermal evaporation sources most notably include refractory boats or tungsten filaments, which enable resistive heating of material to travel with line-of-sight trajectory towards a substrate. These have been foundational in thermal PVD systems due to their ease of use.

2.2. Advantages

- Simplicity: Traditional sources are easier to design, operate, and integrate into vacuum systems. Because of this, custom manufacturing is available for specific processes or chamber configurations.

- Cost-effectiveness: Lower upfront costs and maintenance expenses are attractive for budget-constrained, experimentation, or prototyping operations.

- High-temperature capabilities: Certain refractory boats or filaments are capable of extremely high temperatures, suitable for evaporating high-melting-point materials.

2.3. Challenges

- Material wastage: Without control over the vaporized material, there can be significant material wastage.

- Uniformity issues: Achieving uniform thickness over larger areas can be challenging due to the simplistic vapor flux control.

3. Evaporation Source Selection Table

These comparisons have been generalized in the table below, based on the advantages and challenges described prior. For recommendations for specific materials, more information can be found by contacting the R.D. Mathis team.

Figure 1. Table comparing baffled box sources vs. traditional sources based on process factors.

Evaluating the Baffled Box Source

The choice between traditional thermal evaporation sources and more complex sources, like the baffled box, will be dependent on specific project requirements and system constraints. Overall, understanding the strengths of each evaporation source provides an understanding of the capabilities of the deposition process.

R.D. Mathis Company provides a comprehensive selection of evaporation sources, including both traditional and baffled box configurations, to support a variety of thermal evaporation applications and process requirements. Modifications are available for process-specific solutions through contacting technical support.

Shop our baffled box source selection or contact us with any questions you might have.