Intro to Dual E-Beam Evaporator Source Technology

Dual electron beam (dual e-beam) evaporator sources represent a significant advancement in physical vapor deposition, offering expanded control and flexibility when compared to single e-beam evaporators. This technology enables broad co-deposition processes across applications such as research or thin film electronics.

See more about E-Beam PVD:

Part 1: Revolutionizing Thin Film Deposition

Part 2: Materials, Sources, and Crucibles

Part 3: Dual E-Beam Evaporator Source Technology

1. Dual E-Beam Evaporators

1.1. Introduction

In a dual e-beam process, the system is equipped with two electron guns that produce a beam that causes localized heating which vaporizes materials (in forms such as slugs or pellets), allowing the stream of atoms to condense onto a substrate. As with single gun e-beam systems, the beam is also adjustable to control deposition rates and produce films with precise compositions.

With two of these electron beams, this notably enables co-deposition, or the depositing of two different evaporation materials simultaneously. Due to how e-beam evaporators already handle wide ranges of materials, this increases the versatility in material selection even further.

2. Dual E-Beam Evaporator Source Advantages

Dual e-beam systems offer several advantages over their single-beam counterparts and other deposition techniques. For complex thin film depositions, these advantages provide a valuable use case for these dual systems.

2.1. Deposition Rates

With two independent beams, deposition rates can be higher compared to single-beam systems, optimizing efficiency and process times. Dual-beam configuration allows for better control over thickness uniformity across larger areas, crucial for applications requiring consistent film properties.

2.2. Co-deposition

As stated previously, dual e-beam guns enables co-deposition. The simultaneous deposition of two different materials can be used to mix into complex compounds, such as specific alloy compositions. Multiple pockets in a dual e-beam evaporator enables sequential depositions without breaking vacuum for multi-layer coatings.

3. Applications in Research and Industry

3.1. Use Cases

- Optoelectronics: For depositing thin films used in optical coatings, anti-reflection coatings, and photovoltaic devices. Moreover, dual e-beam can be used to tune refractive indexes or other properties.

- Semiconductor manufacturing: Particularly in the production of integrated circuits and thin-film transistors to control alloy compositions.

- Magnetic storage media: Ni-Fe films can be co-deposited using dual e-beam systems.

- Research and development: Facilitating the exploration of new materials and the development of novel thin-film structures. Used in many nanofabrication facilities.

As seen, dual e-beam evaporator sources are applied for many different use cases across industry and academia. These applications are broadened even further with the different options provided by some dual e-beam deposition systems.

3.2. Combined Thermal Evaporation and Sputtering

Some vacuum systems are designed with thermal evaporator and sputtering capabilities as well. This allows for further co-deposition processes. Notably, some materials may be better suited for resistive thermal evaporator or sputtering, in which case these systems also add a layer of versatility.

Sourcing for Dual E-Beam Evaporation Source Systems

Dual e-beam evaporator sources provides precision and versatility in thin film technology, expanding thin film capabilities by enabling co-deposition. With the possibilities to integrate with other physical vapor deposition processes (thermal evaporation and sputtering), these dual e-beam systems introduce further possibilities.

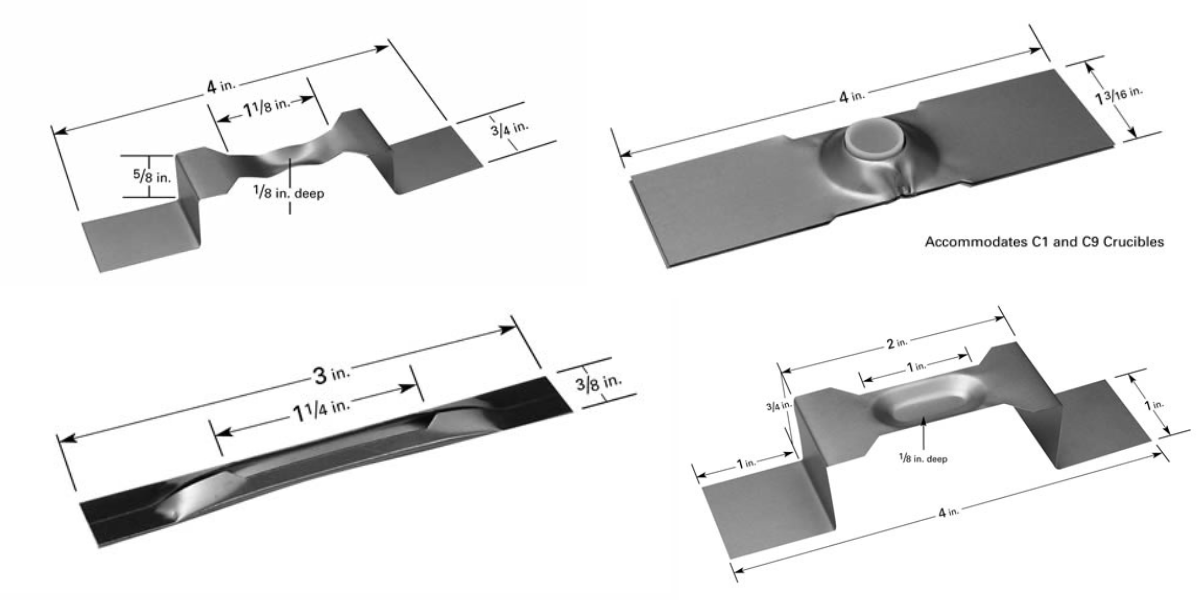

R.D. Mathis Company supplies electron beam liners for advanced thin-film deposition applications. In addition, our production team offers a range of thermal evaporation sources, sputtering targets, and evaporation materials to streamline deposition processes.

Visit our website to shop e-beam liners today, or contact us to get a quote on e-beam filaments or specialty materials.