Applications: Uses for Tungsten Sheet and Refractory Sheet Metals

Refractory metals, including options such as tungsten sheet, exhibit various strong properties in terms of melting points, density, and hardness. As a result, these characteristics provide benefits in environments with elevated temperatures or radiation.

Between tungsten, molybdenum, tantalum, and niobium, relevant industries make use of these for their specialized applications.

1. High Temperature Sheet Applications

Refractory sheet metal are high-performance materials for challenging environments, being classified into the “refractory” label due to their extreme melting points. Because of this, at high temperatures, these sheet materials are durable, thermally stable, and maintain integrity.

1.1. Heat Shielding Applications

Refractory metals are used in many applications where heat shielding is required, resisting high temperatures and also being able to reflect heat back into systems to improve heat retention and efficiency.

In particular, molybdenum sheet metal sees use as a material in vacuum furnaces by creating furnace linings or other components that need to endure operating temperatures. Tantalum and niobium are also used for fabricating shields to protect heat-sensitive components in semiconductor fabrication.

1.2. Resistive Heating Elements

By running current through refractory sheet metal, it creates resistive heating that can go up to temperatures of 2000°C in some cases.

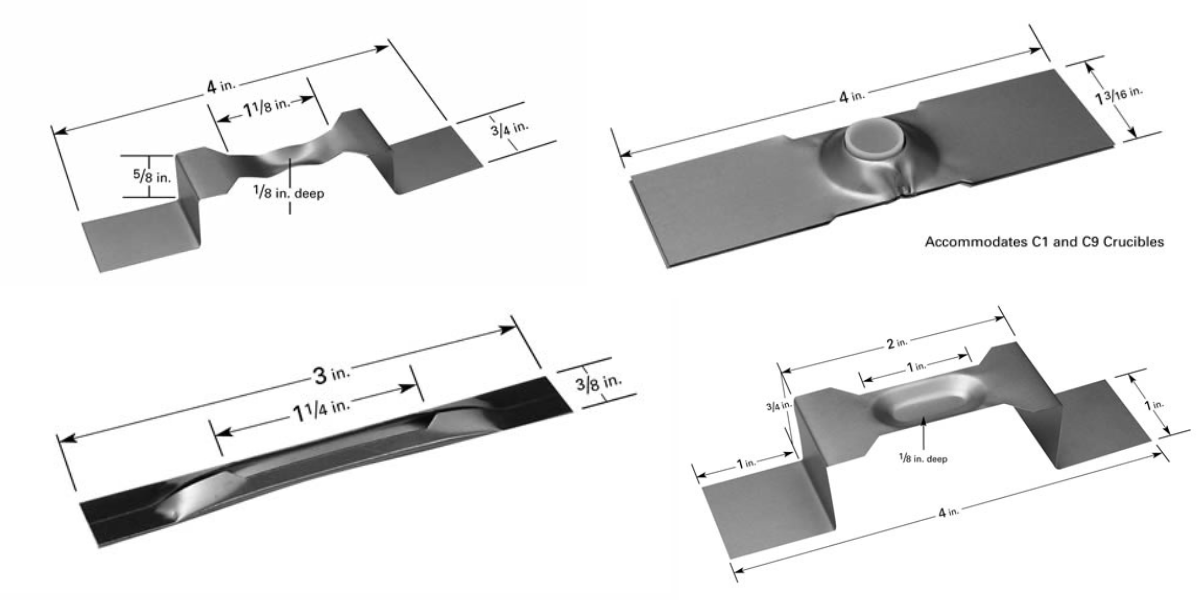

Tantalum, molybdenum, and tungsten sheet are used with this principle to create boats or boxes for thermal evaporation. The temperatures reached in this process enable vaporization of evaporation material held in the boat cavity, also called the dimple. When performed within a vacuum environment, this results in the gas-phase material to condense onto a substrate to form thin-film coatings.

2. Density of Tungsten Sheet

In particular, tungsten is one of the most dense elements on the periodic table, allowing it to exhibit unique characteristics due to this atomic structure.

2.1. Radiation Shielding

As a result of high density, tungsten sheets are highly effective in blocking radiation. Tungsten is used in healthcare and dental applications within medical imaging rooms. To get proper x-ray pictures, tungsten is used as a blocking element when requiring x-rays of specific regions of the human body.

Combined with the previously mentioned heat shielding applications, tungsten sheet metal can both manage heat and radiation in nuclear reactors. This sets it apart from lead, which is potentially more hazardous and is another material used to shield radiation.

2.2. Counterweights

Tungsten plates can be used to compensate for center-of-gravity imbalances or vibrations/oscillations. This is particularly relevant for aerospace applications, where environments may also require durability when these components are subject to high heat or forces.

3. Miscellaneous Applications

Although known for their wear-resistant physical properties, other use cases exist for materials like niobium. Niobium sheet can be used in superconducting applications, as pure elemental niobium has the highest critical temperature among pure elements.

Some of these refractory sheet metals show biocompatibility, expanding their use within medical fields as well. These unique properties make refractory metals useful, despite being more difficult to work with when compared to typical sheet metal materials.

Manufacturers for Tungsten Sheet Parts

At R.D. Mathis Company, we offer a comprehensive range of high-quality tungsten products to meet the most demanding applications. With years of experience in fabrication processes involving refractory sheet metal, our team is capable of working with designs using this material.

Visit the R.D. Mathis website to explore our extensive tungsten, molybdenum, and tantalum sheet products for specialized vacuum requirements.