Specialty Applications of Tungsten Products

Tungsten is a remarkable material known for its high density, strength, and resilience under extreme conditions. Industrial uses for tungsten include forming extremely hard tungsten carbide, fabricating alumina coated tungsten boats, or tungsten shielding against radiation.

1. PVD Processes Utilizing Tungsten

Among different processes within physical vapor deposition (PVD), tungsten is widely utilized due to its high melting point, low vapor pressure, and thermal stability. This includes the following:

- Thermal evaporation

- E-beam evaporation

- Sputter deposition

The role of tungsten and its material properties becomes clearer when examining specific use cases within the aforementioned PVD processes, particularly in components such as alumina-coated tungsten boats, sputtering targets, and crucibles.

2. Tungsten in Thermal Evaporation

Tungsten boats, made out of pure tungsten, are used to resistively heat material for thermal evaporation processes. However, these sources may wear out due to the corrosive properties of certain molten materials, such as gold.

2.1. Alumina Coated Tungsten Boat

Alumina-coated tungsten boats exhibit extended source lifetimes during repeated high-temperature deposition cycles. The alumina coating enhances performance by improving corrosion resistance, increasing thermal stability, and minimizing contamination:

- An alumina layer protects the tungsten boat from corrosive materials, such as nickel, preserving the boat’s integrity and extending operational lifespan.

- The coatings help maintain deposition yield under extreme temperatures by eliminating material migration, ensuring consistent repeatable results.

- Film contamination is minimized, hence leading to higher-quality coatings.

What is barrier coating used for on boat sources?

Barrier-style coatings, such as on the S38B-AO, allow evaporation materials to have good thermal contact with the exposed metal. At the same time, it keeps molten material from escaping due to the “barrier” of aluminum oxide.

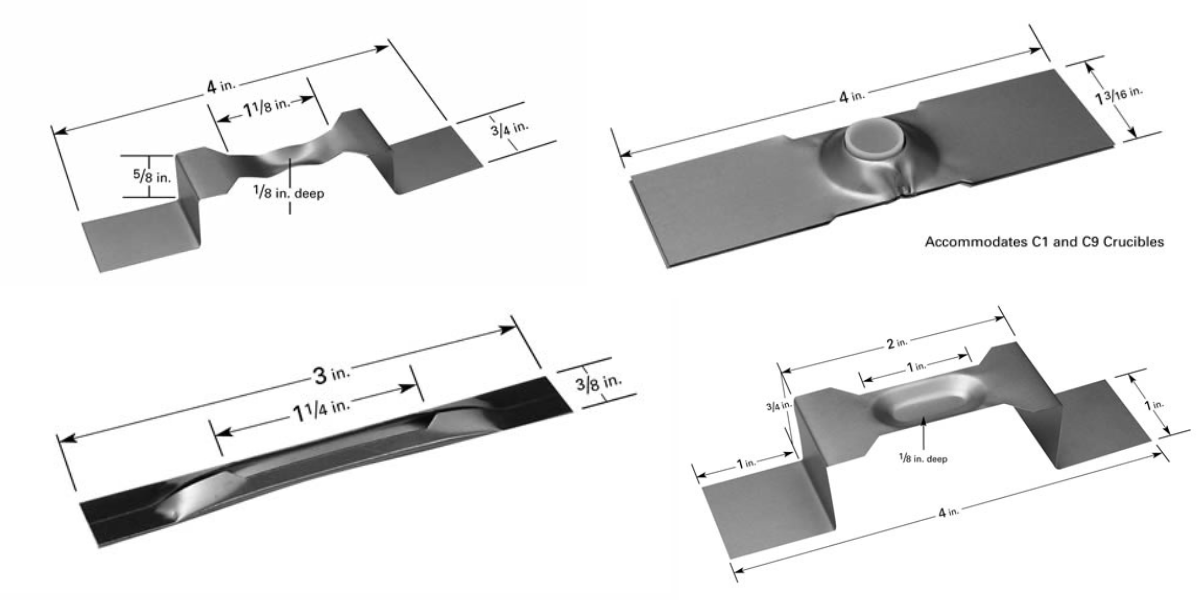

2.1. Tungsten Folded Boats

Folded boats are another variation of the thermal evaporation boat. These boats, however, are designed with higher capacities that a typical boat would not have, facilitating certain advantages over them.

- The higher sidewalls of folded boats allow more capacity than typical boats.

- Folded boats can have customizable lengths and widths of the evaporation area.

For higher volume of material, tungsten folded boats serve as a suitable solution. Contact the R.D. Mathis Company for further information about tungsten folded boats, available upon request.

3. Tungsten in E-Beam Evaporation

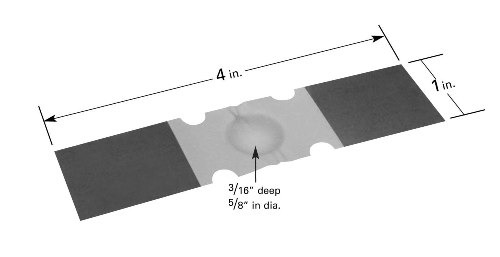

3.1. Tungsten Crucible Liners

For e-beam evaporation, due to the material’s high melting point and resistance to thermal stresses, tungsten crucible liners are selected to contain material undergoing extreme localized heating. Under these heating and vacuum conditions, the low vapor pressure also prevents the tungsten from contaminating the deposition as well.

4. Tungsten in Sputter Deposition

4.1. Tungsten Sputtering Targets

For sputter deposition processes, tungsten acts as the deposition material itself in the form of tungsten sputtering targets. In metallization processes, tungsten has various strengths as a choice of thin film:

- Sputtering targets offer high purity and density, which are crucial for producing quality tungsten thin films for high performance in sensitive electrical applications.

- Tungsten’s thermal conductivity ensures even heating during deposition, enabling uniform films.

- Tungsten sputtering targets are used in a wide range of applications, including semiconductor manufacturing, optical coatings, and solar panels.

The use of tungsten expands to many vacuum deposition technologies, making it versatile and a critical material for many applications.

Sourcing Tungsten PVD Products

Each of these tungsten products provides specific use cases depending on the application.

Additional information about alumina coated tungsten boats, tungsten crucible liners, and tungsten sputtering targets can be found available from R.D. Mathis Company’s technical support.