What is a Tantalum Thermal Boat?

Tantalum thermal boats (or Ta boats) are a type of specific boat-shaped container fabricated from tantalum metal. These are often used for high-temperature environments in the fields of materials science, chemistry, and research laboratories.

Thermal boats can be made from different materials, but tantalum stands out as a refractory metal. Notably, tantalum is versatile due to how it can be shaped and welded into different forms. This enables a level of customization that is needed for various specific high temperature applications.

See also: molybdenum thermal boat and tungsten thermal boat.

1. Design and Purpose

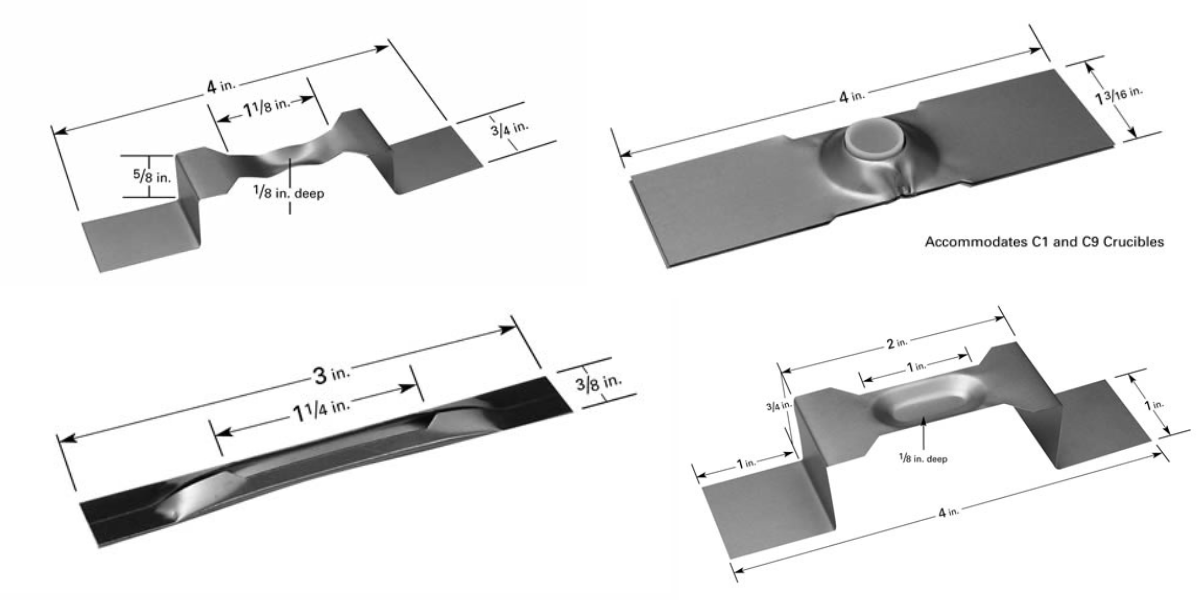

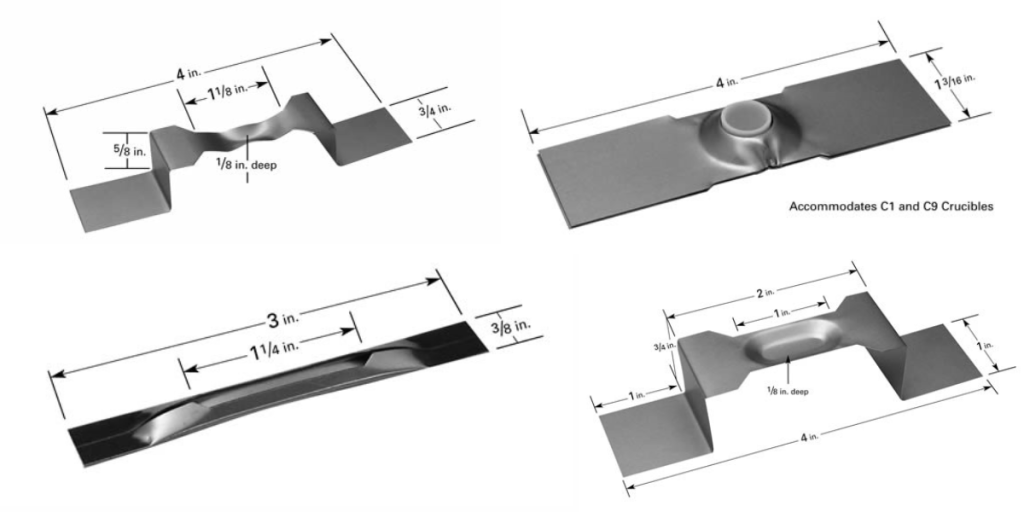

A thermal boat’s design typically consists of a trough-like structure with raised edges that resemble a simple boat. Tantalum is a refractory metal and its high-temperature properties lends itself to a very high melting point, good thermal conductivity and resistance to chemical attack at elevated temperatures.

The main purpose of a tantalum thermal boat is to hold and transport materials during high-temperature processes, such as thermal evaporation and furnace applications. These boats are loaded with solid materials which need to be heated to high temperatures to facilitate vaporization.

2. Common Applications

As a refractory metal, tantalum is able to withstand high-temperatures without deforming or reacting with the materials it holds, making it essential for research and industrial applications.

2.1. Thin Film Deposition

- In physical vapor deposition (PVD) processes, tantalum boats are used to hold the evaporant material (e.g., metal, alloy or other material) that is heated to produce a vapor. This vapor then condenses on a substrate, forming a thin film.

- Special tantalum boats offer higher capacity than typical boats and can be used with baffling and covers to control vapor streams.

2.2. High-Temperature Reactions

- Tantalum boats or furnace elements see use during high-temperature reaction applications that require precision control and containment of reactants.

2.3. Materials Testing

- These boats are used in laboratories in conjunction with various material characterization and analysis techniques, allowing preparation for thermal analysis, high-temperature microscopy and thermogravimetric analysis.

Due to its formability, tantalum thermal boats can be fabricated to different sizes, thicknesses, and configurations. Additionally, tantalum can be formed into boxes and heating elements durable for very specific applications for different requirements.

Sourcing Tantalum Thermal Boats

R.D. Mathis Company manufactures tantalum thermal boats for high-temperature thin-film deposition applications. These components are fabricated in the United States from high-purity tantalum and exhibit excellent thermal conductivity and strong resistance to corrosion under elevated operating temperatures.

All of our evaporation boats are available in a variety of materials and thicknesses — visit our website to shop now.