About Tungsten Evaporation Sources

In thermal evaporation, pure tungsten is used (in the form of boats, filaments, or rods) due to its high melting point, low vapor pressure, and chemical inertness, which provides high compatibility with the elevated temperatures needed to form thin film coatings.

1. What Are Tungsten Evaporation Sources?

Tungsten evaporation sources are components made from high‑purity tungsten used to contain and heat source materials until vaporization occurs within a vacuum chamber. These include:

During vacuum evaporation, the tungsten boat is heated using a power source such as a high-current power supply. As the temperature of the tungsten evaporation source increases due to resistance heating, the material inside begins to vaporize and deposit on the substrate.

2. Tungsten Evaporation Boats

2.1. Function

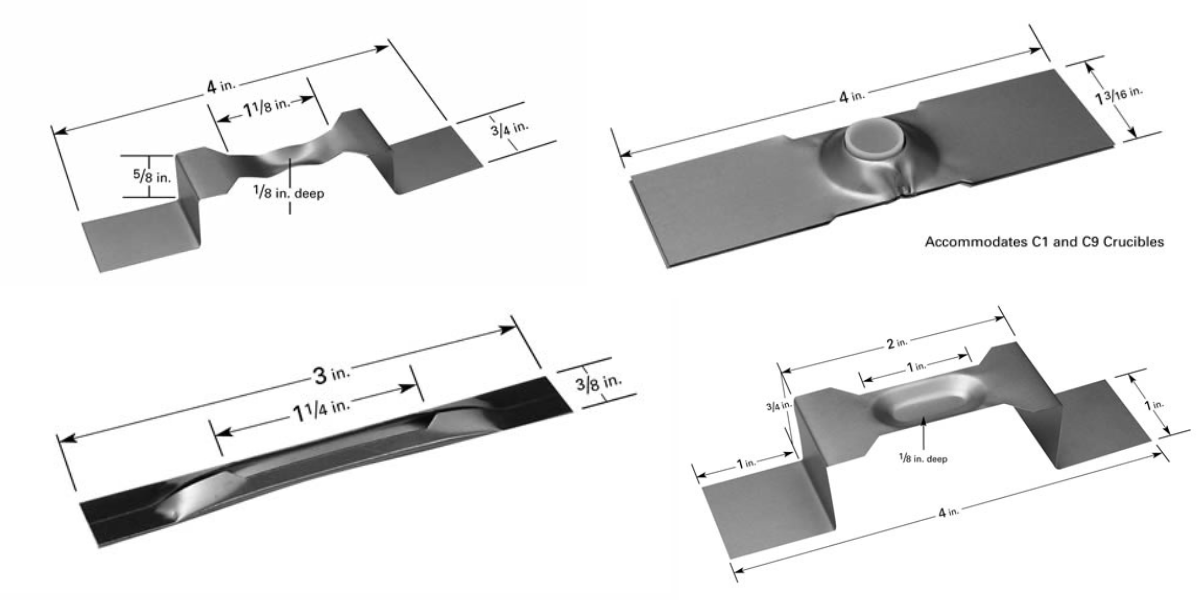

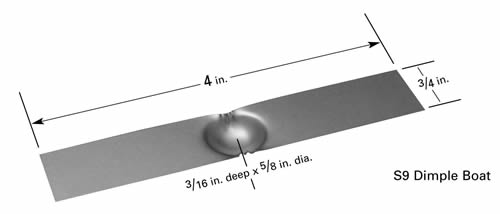

Tungsten boats are resistively heated elements with a recess, or “dimple”, that contains evaporation material during thermal evaporation. The most simple form of this evaporation source is a rectangle with a dimple in the center, as shown with the S9 Dimple Boat. However, many different geometries can be applied for these boats.

Tungsten boats are ideal for use with high-melting-point materials, such as titanium. They are also commonly used in the semiconductor industry for thin-film deposition of electrical contacts.

2.2. Design

One design aspect that affects the boat is the dimple area, which can be fabricated to different capacities. Round circular dimples focus evaporation material in the center, but dimples can also be formed into a long pan shape instead.

Bends on a boat source can be used to accommodate for thermal expansion when clamped into electrodes. Compared to flat boats, this geometry helps with maintaining the boat lifetime when exposed to repeated high temperature cycles.

3. Tungsten Filaments

3.1. Function

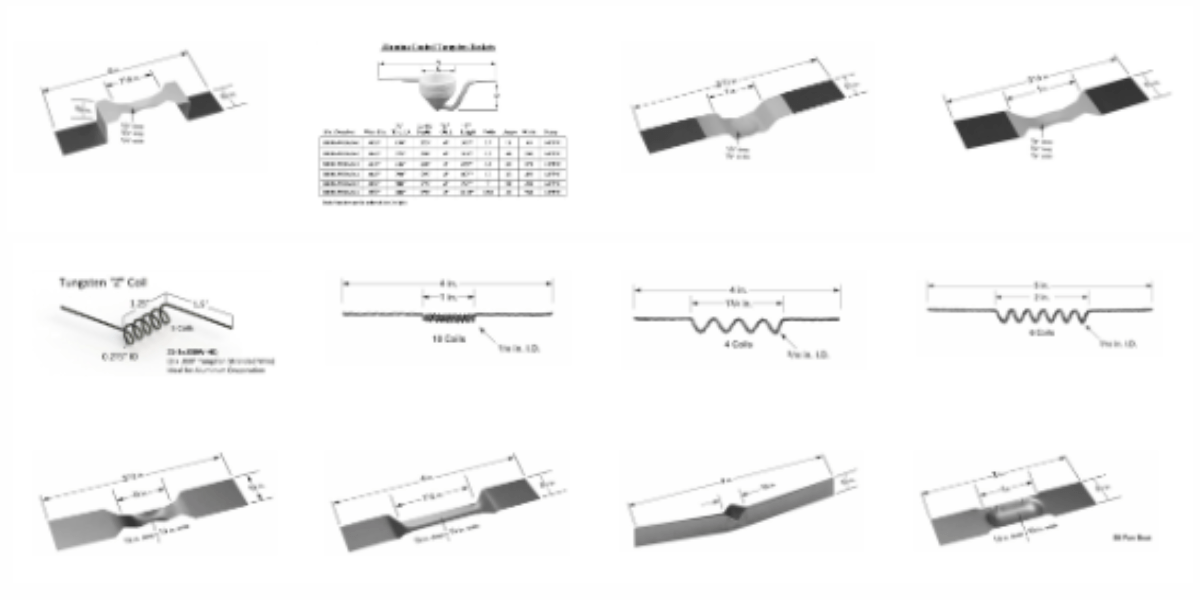

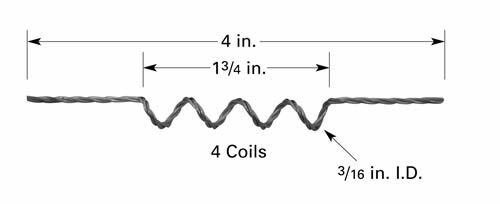

Tungsten filaments operate similarly to tungsten boats. However, material (in the form of wire, canes, or clips) is held onto these sources due to how material wets onto the surface area of the filament. This type of source can be versatile and have low operating costs.

3.2. Design

These high-purity tungsten wire filaments are available in a variety of diameters and lengths. For varying applications, ranging from optical to semiconductor coatings, this type of source is easily customizable upon request.

- Stranded filaments increase surface area, enabling more material to wet onto the source.

- Tungsten filaments can withstand extremely high temperatures without melting, which is essential for high-temperature electronics.

- Filaments can provide focused evaporation while requiring low power to operate.

- The strength of tungsten filaments ensures a longer operational life compared to other materials, reducing the frequency of replacements.

Tungsten filaments see use in many vacuum coating processes.

Although these filaments are used in PVD for thermal evaporation, electron beam filaments can also be made out of tungsten. In general, tungsten filaments see use across much across research as a high temperature heating element.

4. Tungsten Rods

4.1. Function

Tungsten rod sources are similar to tungsten filaments in that they also operate using the wetting principle. However, this larger diameter source is more durable than typical tungsten filaments, making it an option for corrosive materials like aluminum.

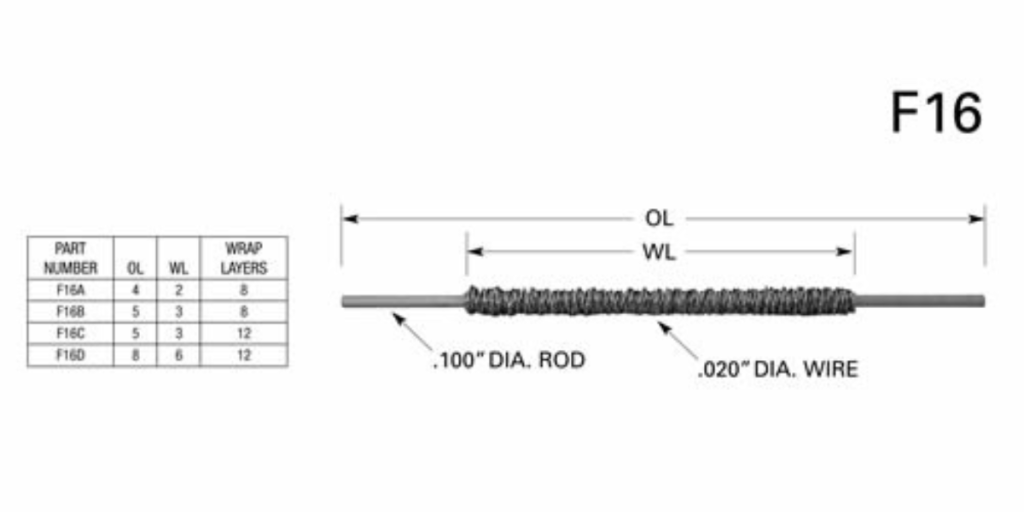

4.2. Design

The tungsten rod is wrapped with layers of tungsten wire to increase its surface area, and evaporation material can be wrapped on top of this tungsten wire.

This can also be preloaded with materials such as nickel, making it ready-to-use upon receipt. For more technical info, contact R.D. Mathis Company about sourcing.

Tungsten Boats, Filaments, and Rods

R.D. Mathis Company manufactures a broad range of tungsten boats, filaments, and rod sources for thin-film deposition applications. These components are produced using high-purity materials and are available in a wide variety of configurations to accommodate different evaporation requirements.

Additional technical information on tungsten boats, filaments, and rod sources is available through the R.D. Mathis Company.