The Advantages of Using a Boron Nitride Crucible in High-Temperature Applications

In the realm of high-temperature materials and applications, using boron nitride crucibles has emerged as a game-changer, revolutionizing industries such as semiconductor manufacturing, materials research and metal melting. These crucibles, made from a compound of boron and nitrogen (BN), offer a range of advantages that set them apart from traditional crucible materials like graphite or ceramics.

Inert and Non-Wetting

Boron nitride exhibits excellent chemical inertness. It does not react with most molten metals, ceramics, or other materials commonly used in high-temperature processes. This property prevents contamination and ensures purity of the materials being processed, a critical factor in industries like electronics and metallurgy, or preserving the purity of thin films.

This non-wetting property makes is an ideal material to reduce creeping during thermal evaporation, preventing material from going up the crucible wall and escaping.

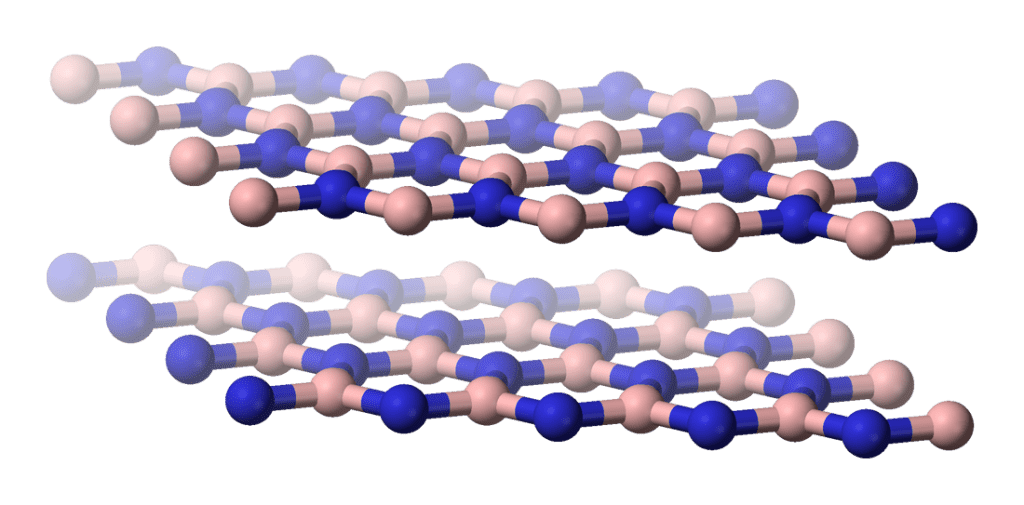

Diagram: Chemical structure of hexagonal boron nitride

Exceptional Thermal Properties

A boron nitride crucible can withstand temperatures exceeding 2000°C without undergoing significant structural changes. The low coefficient of thermal expansion of boron nitride helps maintain the integrity of the crucible even when exposed to rapid temperature changes. This makes boron nitride and ideal for processes requiring extreme heat, such as crystal growth, thermal analysis, and ceramic sintering.

Boron nitride’s high thermal conductivity allows for efficient heat transfer, leading to uniform temperature distribution within the crucible. As a result, the processed materials experience minimal temperature gradients, reducing the risk of thermal stress and improving overall process control for procedures like material synthesis.

Excellent Electrical Insulation

In industries like semiconductor manufacturing, where precise control of electrical properties is crucial, boron nitride’s electrical insulating properties come to the forefront. It allows for the handling of materials without unwanted electrochemical reactions or interference, ensuring the integrity of the final products.

Shop boron nitride crucibles, boron nitride composite crucibles, and evaporation sources today.

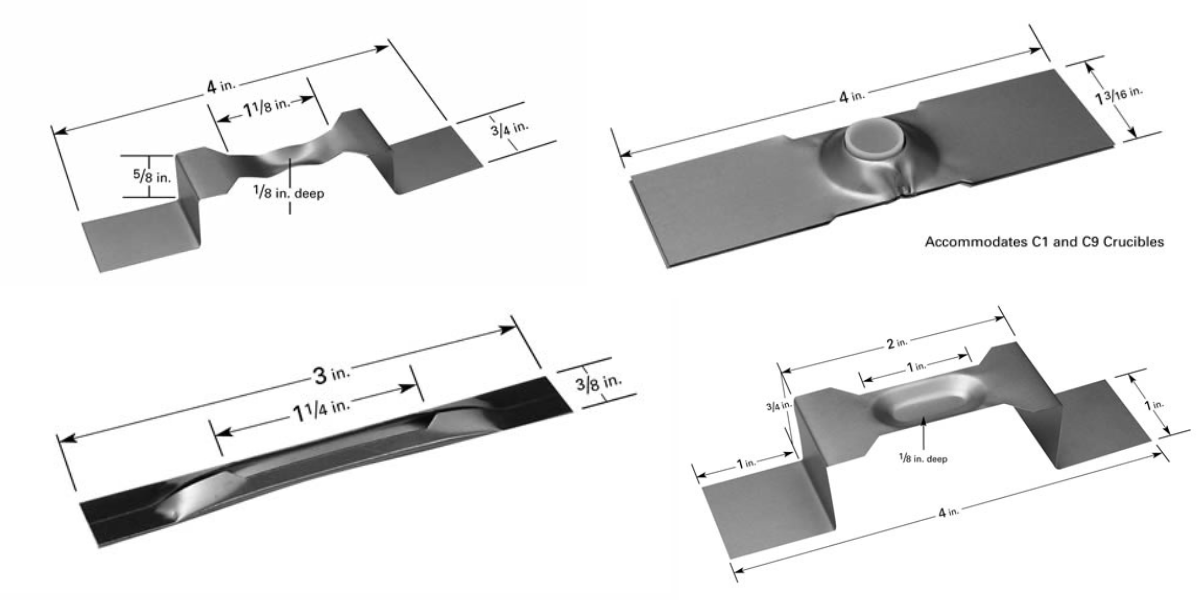

Easy Moldability and Customization

Boron nitride is highly moldable, enabling the production of crucibles in various shapes and sizes. This flexibility facilitates the optimization of crucible designs for specific processes, ensuring efficient material usage and reduced waste. Boron nitride can also be incorporated into composite materials, allowing further customization depending on the application.

Shop Our High-Quality Boron Nitride Crucibles

Renowned for our superior quality and precision engineering, R.D. Mathis Company’s boron nitride crucibles are designed to excel in the most demanding high-temperature applications.

Shop our collection of crucibles and evaporation sources today.