How Certain Materials for Evaporation Impact Thin Film Characteristics

Thin film deposition is a crucial process in various industries, ranging from electronics to optics. The materials used for evaporation play a pivotal role in determining the characteristics and performance of the thin films produced.

Let’s explore the impact of specific evaporation materials on thin film properties:

The Significance of Evaporation Materials

The thin film deposition process involves the deposition of a thin layer of material onto a substrate, and the choice of evaporation material significantly influences the properties of the resulting film. The characteristics of the material, such as its melting point, thermal stability, and conductivity, all contribute to the final thin film’s attributes.

Example: Aluminum and Tungsten Evaporation Materials

Tungsten, with its high melting point and excellent thermal stability, is a robust evaporation material widely employed in thin film deposition processes. When utilized, tungsten contributes to the formation of durable and heat-resistant films. Its applications extend to the production of microelectronic devices, aerospace components, and coatings for high-temperature environments.

Aluminum, known for its low melting point and exceptional thermal and electrical conductivity, is a staple in thin film deposition. When employed, aluminum facilitates the creation of lightweight yet sturdy films with widespread applications. Its use spans from semiconductor manufacturing to protective coatings and packaging materials in the electronics industry.

Considerations for Specific Applications

Different industries require specific thin film characteristics to meet their unique needs. Whether it’s in semiconductor manufacturing, optics, or electronics, the selection of the right evaporation material is paramount. Factors such as conductivity, adhesion, and transparency must be carefully considered to ensure optimal performance in the intended application— an example we saw from the aluminum and tungsten evaporation comparison.

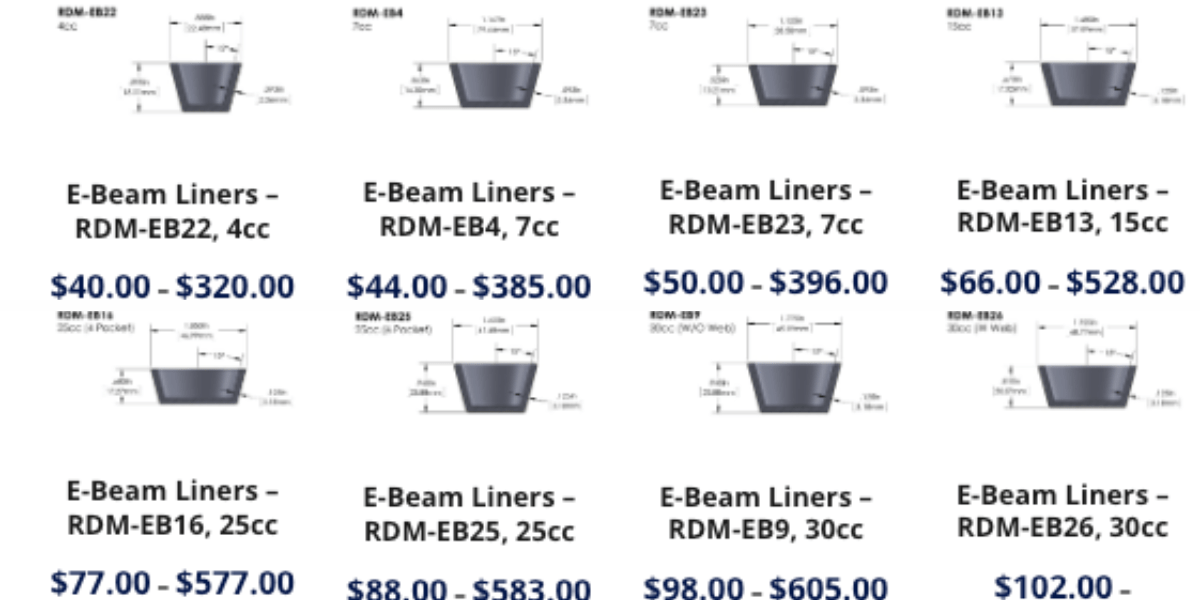

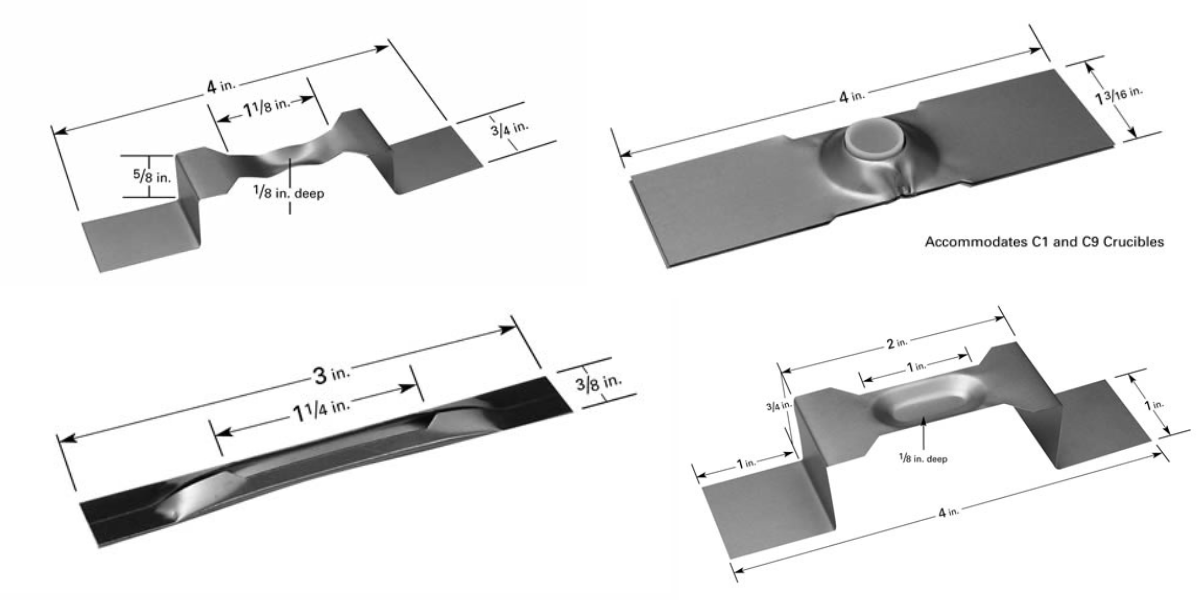

Shop R.D. Mathis Company’s Collection

With a reputation for excellence, R.D. Mathis Company stands as a prominent provider of high-quality evaporation materials, contributing to advancements in materials science and engineering.

Visit our website to shop our collection.